Vacuum Pressure Casting Machines

HASUNG machina ekukanda akakodzera kunyungudusa uye kukanda masimbi ekushisa kwakanyanya kunyungudika. Maererano nemuenzaniso, vanogona kukanda uye kunyunguduka goridhe, Karat goridhe, sirivha, mhangura, alloy neTVC, VPC, VC series, uyewo simbi, platinamu, palladium ine MC series.

Pfungwa huru yeHASUNG vacuum pressure casting machines ndeyekuvhara chivharo nekutanga kudziyisa kana muchina wazadzwa nesimbi.

Kupisa kunogona kusarudzwa nemaoko.

Izvo zvinhu zvakanyungudutswa pasi pekudzivirira gasi (argon/nitrogen) kudzivirira oxidation. Nzira yekunyunguduka yaigona kuonekwa zviri nyore nehwindo rinoona. Iyo crucible inoiswa nechepakati muchikamu chepamusoro chemhepo-yakasimba yakavharwa aluminium chamber mukati meiyo induction spool. Panguva ino iyo flask ine inopisa yekukanda fomu inoiswa muchikamu chezasi chesimbi isina tsvina yevacuum chamber. Imba yevacuum yakarereka uye yakasungirirwa pasi pe crucible. Pakukanda maitiro, crucible inoiswa pasi pekumanikidzwa uye flask pasi pevacuum. Musiyano wekumanikidza unotungamira iyo simbi yemvura mune yakanakisa ramification yefomu. Dzvinyiriro inodiwa inogona kuiswa kubva 0.1 Mpa kusvika 0.3 Mpa.

Iyo vacuum inodzivirira mabubbles uye porosity.

Mushure mezvo imba yekutsvaira inovhurwa uye flask inogona kubudiswa kunze.

Iyo TVC, VPC, VC yakatevedzana michina yakashongedzerwa neflask inosimudza iyo inosundira flask yakananga kune caster. Izvi zvinorerutsa kubviswa kweflask.

Iyo MC yakatevedzana michina iri kurereka vacuum yekukanda mhando, ine 90 madhigirii inotendeuka yakanyatso kugadzirirwa kupisa tembiricha yekukanda simbi. Yakatsiva centrifugal casting.

-

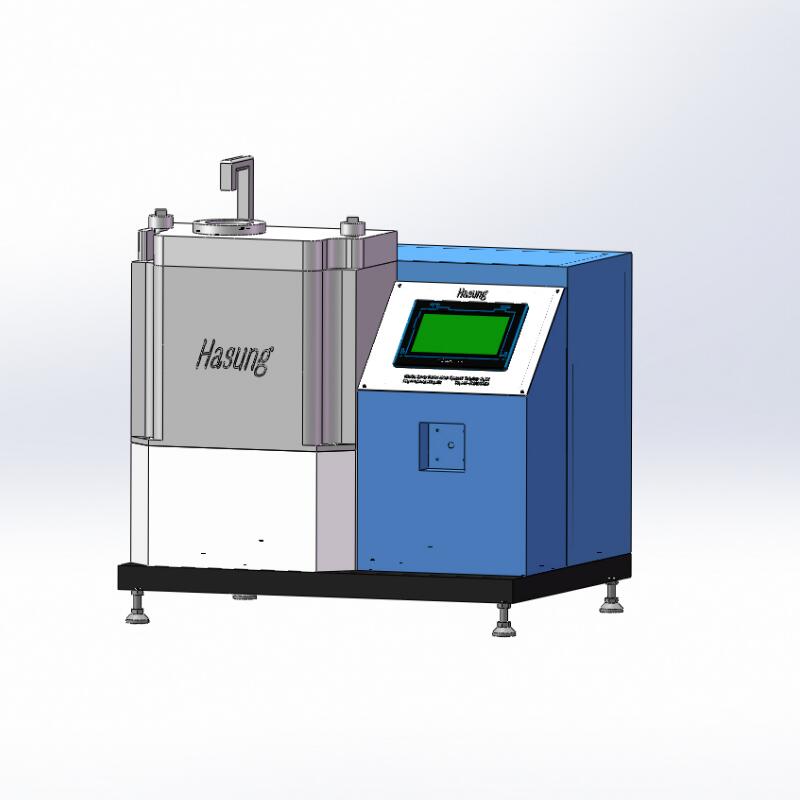

VCT Series Vacuum Pressure Casting Machine ine PLC Kubata Screen

NEXT vacuum pressure machine naHasung ndiwo muchina wako unotevera kugadzira mhando.

1 Tsigira flask ine flange uye flask isina flange

2. Kukurumidza kunyunguduka kwakanaka, kuchengetedza simba

3. Inert Gas - ine zvidimbu zvakanaka zvekuzadza

4. Yegeji chaiyo nekuvandudzwa kwekunzwa kudzvanywa

5. Zviri nyore kuchengetedza

6. Yakarurama yekumanikidza nguva

7. Kuzviongorora - Taiwan Weinview PLC touch panel auto-tuning

8. Nyore kushanda, bhodhoro rimwe kupedzisa yose yekukanda maitiro9. Mushure modhi pasina oxidation

10. Kupisa kwakasiyana-siyana kwekurasikirwa kwegoridhe

11. Vacuum pressure, argon pressure, tembiricha, nguva yekudira, nguva yekumanikidza, vacuum nguva.

-

VCTV Series Jewelry Vacuum Pressure Casting Machine ine Vibration System

NEXT vacuum pressure machine naHasung ndiwo muchina wako unotevera kugadzira mhando.

1. Maitiro maviri eflask ane flange uye flask isina flange

2. Vibration system yekukanda zvakanaka

3. Kuwedzera kusanganisa kwekuparadzanisa kwakanaka kwegoridhe

4. Kukurumidza kunyunguduka kwakanaka, kuchengetedza simba

5. Inert Gas - ine zvidimbu zvakanaka zvekuzadza

6. Yegeji chaiyo nekuvandudzwa kwekunzwa kudzvanywa

7. Zviri nyore kuchengetedza

8. Yakarurama yekumanikidza nguva

9. Kuzviongorora - Japan Mitsubishi PLC touch panel auto-tuning

10. Nyore kushanda, bhodhoro rimwe kupedzisa yose yekukanda maitiro11. Mushure modhi pasina oxidation

12. Kupisa kwakasiyana-siyana kwekurasikirwa kwegoridhe

13. Vacuum pressure, argon pressure, tembiricha, nguva yekudira, nguva yekumanikidza, vacuum time, vibration time, vibration hold time inogona kusetwa, Chirongwa cheflask chine flange, chirongwa cheflask isina flange, zvese zviripo, auto mode uye manual mode. zviripo.

-

TVC Series Induction Vacuum Pressure Kukanda Machine yeGoridhe Silver Copper

Yakazara otomatiki Vacuum Pressure Kukanda Machine

Tekinoroji nyowani yekusimudzira mhedzisiro yekukanda

Iyo Hasung Casting System

1.Kuvhara chivharo otomatiki, zvese zviri otomatiki kushanda pakukanda kazhinji zvinovandudza kuyerera kwezvinhu uye kuzadza mold.

2.Castings inoratidzira yakakwirira uye inopindirana density

3.Porosity yakanyanya kuderedzwa

4. Kutsungirira Max. 4 mabara ekukanda kumanikidza.

5. SBS yekucheka system pasina kushandisa gaskets, chengetedza mari.

6.Castings vane kunyanya kunetseka uye elasticity zvinhu, zvichiita kuti zvive nyore kugadzirisa mberi.

7. Easy touch operation ine inobatsira parameter screen

8. 100 zvirongwa zviripo.

-

VPC Series Vacuum Pressure Kukanda Machine yeJewellery

Kudzvinyirira pamusoro peVacuum Casting Machines

VCT imhuri yekudzvinyirirwa pamusoro pemichina yekukanda vacuum yakagadzirirwa kusangana nezvinodiwa zvakanyanya mukurasika kukanda wakisi kugadzirwa kwegoridhe, K-goridhe, mhangura, bhuronzi, alloys. Ivo vanowanzo shandiswa kubatanidza kune 3d printa yekukanda yakananga kuti iwane yekutanga simbi zvikamu zvezvakaoma zvinhu.

Iyi mhuri yemichina inoshanda neitsva, inoshandura kaviri kamuri pfungwa. Iyi innovative system inopa akati wandei mabhenefiti kana ichienzaniswa neyechinyakare single chamber suction system iripo pamusika.

MuVCT, kamuri yekunyunguduka uye kamuri yeflask hazviregi zvachose: paunenge uchikanda, muchina unogona kudzora jekiseni resimbi mu mold nekuisa mutsauko wekumanikidza panguva yekudira. Izvi zvinobereka jekiseni rinokurumidza kana zvichienzaniswa nekungodururwa kwegiravhiti zvine pundutso yekukanda zvinhu pane tembiricha yakaderera. Izvi zvichaguma nekupedzisa kwepamusoro pepamusoro uye kuderedza shrinkage yezvikamu zvakakandwa.Iyo yekukanda kutenderera inotora maminetsi mashoma uye, nepo furasiki yapfuura ichitonhora pasi mukudzivirira gasi pasina oxidation, iyo inotevera inochaja inogona kutakurwa mucrucible uye yakanyungudutswa, nekudaro ichipindirana mavhiri maviri pasina kutambisa nguva.

Muchina uyu unongozviitira otomatiki, une PC yakavakirwa yekutarisa sisitimu yekutora maparamendi ekutora uye kugadzira data manejimendi, ine nyore kugadzirisa kwekukanda zvirongwa zvakakodzera kune akawanda marudzi ealloy.

Uyu muchina weshanduko ndiyo synthesis yeinjiniya yepamusoro uye makore echiitiko mukukandira iyo chete Hasung ichaunza mufekitori yako.

-

Hasung T2 Jewelry Vacuum Pressure Casting Machine

NEXT vacuum pressure yekukanda muchina neHasung ndiyo yako inotevera muchina kugadzira mhando.

T2 zvakanakira:

1. Mushure modhi pasina oxidation

2. Kupisa kwakasiyana-siyana kwekurasikirwa kwegoridhe

3. Kuwedzera kusanganisa kwekuparadzanisa kwakanaka kwegoridhe

4. Kunyungudika kwakanaka

5. De-Gas - ine zvimedu zvekuzadza zvakanaka zvesimbi

6. Yakakwana kaviri-tsono geji ine yakagadziridzwa kudzvanywa kunzwa

7. Zviri nyore kuchengetedza paunenge uchikanda

8. Yakarurama yekumanikidza nguva

9. Kuzviongorora - PID auto-tuning

10. Memory yeparameter yekukanda zvakanaka

11. Kukanda System Vacuum pressure casting system - max. kudzvanywa 0.3MPa nemukati gasi tangi

12. Kutsiva Gasi Single gasi (Argon)

13. Chirongwa Memory 100 ndangariro

14. Kudzora Yakanyatsogadzirwa microprocessor control. Kudzora tembiricha nePID nekururama kwe +/-1 madhigirii centigrade.

15. Heating Induction heat (ine yakanyatsogadzirirwa simbi inomutsa basa). -

Mini Vacuum Pressure Kukanda Machine yePlatinum Palladium Steel Gold Silver

Hasung Precious Metals SVC/MC Equipment zvakanakira

Iyo SVC / MC yakatevedzana yakanyanyisa kuchinjika michina yekukanda yakakodzera kune akasiyana maapplication ekukanda simbi - uye akati wandei sarudzo dzaionekwa sedzisingawirirane kusvika zvino. Saka, nepo MC dzakatevedzana dzakagadzirwa semuchina wekukanda wepamusoro wekukanda simbi, palladium, platinamu nezvimwe (max. 2,100 ° C), maflasks makuru anoita kuti ive yakakodzera kugadzirwa kwehupfumi kuburitsa goridhe, sirivha, mhangura, simbi, alloy nezvimwe zvinhu.

Muchina uyu unosanganisa maviri-chamber differential pressure system ine tilting mechanism. Iyo yekukanda maitiro inowanikwa nekutenderedza iyo yese yekunyungudika-kukanda unit ne90 °. Imwe bhenefiti yetilting system ndeye kushandiswa kwemutengo wehupfumi graphite kana ceramic crucibles (isina maburi uye yekuvharisa tsvimbo). Izvi zvinowanzova nehupenyu hwesevhisi hurefu. Mamwe alloys, akadai semhangura beryllium, anokurumidza kuita kuti macrucibles ane maburi uye masimbi ekuisa chisimbiso ave asina kusimba uye saka asingabatsiri. Nechikonzero ichi, macaster mazhinji kusvika parizvino akagadzirisa alloys akadaro chete mumasisitimu akavhurika. Asi izvi zvinoreva kuti havagone kusarudza kukwidziridza maitiro nekuwedzeredza kana vacuum.

-

Tilting Vacuum Pressure Casting Machine yePlatinum Palladium Goridhe Sirivha Siri

Hasung Precious Metals Equipment zvakanakira

Chigadzirwa chine ruvara rwakafanana uye hapana kupatsanurwa:

Iyo porosity yakaderedzwa, uye density yakakwira uye inoramba iripo, ichideredza post-processing basa uye kuderedza kurasikirwa.

Zvirinani kunyungudika kwezvinhu uye kuzadza mold, njodzi yakaderera yekufarira:

Vibration inovandudza kuyerera kwezvinhu, uye chimiro chechinhu chakanyanya compact. Kuvandudza chimiro kuzadza uye kuderedza njodzi yekupisa kunopisa

Saizi yezviyo inoderedzwa kusvika 50%:

Kusimbisa neyakajeka uye yakawanda yakafanana chimiro

Zvirinani uye zvakagadzikana zvezvinhu zvivakwa:

Iko kusimba kwesimba uye elasticity inowedzerwa ne25%, uye iyo inotevera yekugadzirisa mashandiro inovandudzwa.

Mubvunzo: Chii chinonzi Vacuum Casting Method?

Investment castings, iyo inowanzonzi yakarasika-wax castings, zvikamu zvesimbi zvinogadzirwa neinvestment casting process. Iyi inoshandisika mold process uye zvikamu izvo zvinogadzira zvinonyanya kufarirwa kune zvisingaverengeke maapplication mumaindasitiri mazhinji. Izvi zvinonyanya kukonzerwa nekuti iyo yekudyara dhizaini inoita kuti zvikwanise kugadzira zvikamu zvakaoma zvine hunhu hunoshamisa hwepamusoro uye huchokwadi muhuwandu hwakawanda hwezvinhu uye saizi. Nekudaro, kana chikamu chichida zvakadzama zvakadzama kana undercuts, zvinhu zvinosimbiswa nefiber kana waya, kana kuvharirwa kwemhepo idambudziko, imwe mhando yekudyara nzira yekukanda inoshandiswa. Iyi nzira yekukanda mari haisi imwe kunze kwevacuum casting nzira, iyo yakagadzira vacuum castings. Chii chinonzi vacuum castings? Ramba uchiverenga kuti uzive.

Chii chinonzi Vacuum Investment Castings?

Vacuum castings inhengo dzesimbi dzinogadzirwa nenzira yevacuum casting. Iwo akasiyana pane akajairwa ekudyara castings nekuda kwehunyanzvi hunoshandiswa kugadzira zvikamu zvesimbi izvi. Iyo nzira inotanga nekuisa chidimbu chepurasita mukamuri yekutsvaira. Vacuum yacho inobva yakwevera simbi yakanyungudutswa muforoma. Pakupedzisira, kuumbwa kunosimbiswa muovheni uye mold yacho inobviswa kuitira kusunungura chigadzirwa chekupedzisira.

Kana iwe uine purojekiti inoda emhando yepamusoro vacuum investment castings yezvishongo kana mamwe masimbi, tinogona kukupa iwo. Pano paHasung, isu tinoshandisa ese ari maviri giravhiti akadyiswa uye vacuum yekukanda nzira kugadzira goridhe, sirivheri, platinamu, zvinhu zvesimbi zvinosiyana. Makore edu asingaverengeki echiitiko mune mbiri idzi nzira dzinovimbisa kuti tinokwanisa kupa epamusoro kana pedyo net mambure maumbirwo ayo anoda shoma kana kusapedza basa. Tora majekiseni ekudyara aunoda, akaunzwa nenguva uye nemutengo unokwikwidza, nekutibata nesu nhasi!

Mubvunzo: Nzira yekukanda zvishongo?

Jewelry casting inzira yekugadzira zvidimbu zvezvishongo zvinosanganisira kudirwa kwemvura yesimbi alloy muforoma. Inowanzo kunzi yakarasika-wax casting nekuti mold yekukanda inogadzirwa uchishandisa wakisi modhi inonyungudutswa kusiya kamuri isina mhango pakati peforoma. Iyo tekinoroji yakashandiswa kwezviuru zvemakore, uye ichiri kushandiswa zvakanyanya nhasi nevese mhizha mhizha uye mhizha dzekumba kugadzira chaizvo kudhirowa kwezvimedu zvezvishongo zvepakutanga. Kana iwe uchifarira kugadzira zvishongo zvako uchishandisa nzira yekukanda, tevera matanho aya ekukanda zvishongo.

1. Kugadzira Mold Yako

1) Veza chidimbu chewakisi yakaoma yekuenzanisira muchimiro chaunoda. Tanga zviri nyore ikozvino, sezvo molds dzakaoma zvakanyanya kuchengetedza pamwechete pakutanga. Tora chidimbu chewakisi yekuenzanisira uye shandisa banga chairo, Dremel, uye chero chishandiso chinodiwa kugadzira modhi yezvishongo zvako. Chero chimiro chaunogadzira ikozvino chichava chimiro chechidimbu chako chapera.

Iwe uri kugadzira mufananidzo chaiwo wezvishongo zvako zvekupedzisira.

Kushandisa chidimbu chezvishongo zvaunoda semuenzaniso kuchakubatsira kugadzira zvidimbu zviri nani paunotanga.

2) Batanidza 3-4 "sprues," waya wewakisi inozopa gwara rekuti wakisi inyunguduke gare gare. Uchishandisa imwe wakisi, gadzira tambo refu dzakati wandei kubva muwakisi wodzisungirira kune modhi kuitira kuti dzose dzibude kubva pachidimbu. Izvi zviri nyore kunzwisisa kana ukaona hurongwa hwese-iyi wakisi ichavharwa nepurasita, yobva yanyungudutswa kuita buri rechimiro chechimiro chako. Iwe wobva wazadza mugomba chikamu nesirivha. Kana ukasagadzira sprues, wakisi yakanyunguduka haigoni kubuda uye kuita nzvimbo isina mhango.

Kune zvidimbu zvidiki, semhete, ungangoda sprue imwe chete. Zvidimbu zvakakura, semabhandi mabhandi, zvingada kusvika gumi.

Mapiritsi ese anofanira kusangana panzvimbo imwe chete. Vachada kubatanidzwa kune sprue base.

3) Batanidza mold kune sprue base uchishandisa zvishoma yerabha yakanyungudutswa. Masprue ese anosangana pamwe chete, uye unoisa mold kune sprue base panosangana masprue ese. Izvi zvinoita kuti wakisi inyunguduke nepasi pegasi yosiya mold.

4) Isa furasiki pamusoro pe sprue base, kuve nechokwadi kuti une inch inch pakati pemadziro eflask nemuenzaniso. Flask icylinder hombe inotsvedza pamusoro pechigadziko chesprue.

2. Kuisa Mold

1) Chengetedza modhi yewakisi pasi pefurasiki, uchishandisa wakisi yakanyungudika. Iyo modhi inofanirwa kutsigirwa muflask. Yakagadzirira kugadzirwa kwezvishongo.

Ongorora: Muvhidhiyo, iyo yakawandisa sirivheri zvikamu zvimwe zvidimbu zvezvishongo zvinoenda pamwe nebhandi bhandi. Iwo haasi mamwe masprues kana anodiwa ekuwedzera.

2) Sanganisa zvimisikidzo zvakaomeswa zvegypsum plaster-based investment mold material nemvura, sekurairwa kwemugadziri. Tevedzera mirairo yechero yekudyara mold yaunosarudza kutenga-inofanira kunge iri nyore seti yezviyero.

Pfeka mask kana mhepo yekufemerera pese pazvinogoneka paunenge uchishanda nehupfu iyi-hazvina njodzi kufema.

Enda mberi kana iwe uine musanganiswa kuenderana kwepancake batter.

3) Isa iyo mold yekudyara mukamuri yekutsvaira kuti ubvise chero mabhuru emhepo. Kana iwe usina vacuum sealer, unogona kungoirega igare kwemaminetsi gumi-20. Mhepo dzemhepo dzinogadzira maburi, ayo anogona kubvumira simbi kupinda mukati uye kugadzira chidimbu chekupedzisira chezvishongo.

4) Dururira musanganiswa weinvestment mold muflask, wakatenderedza modhi yewakisi. Iwe unozovhara zvachose mold yako mune plaster. Vhurazve musanganiswa kuti ubvise chero maturu ekupedzisira asati aenderera mberi.

Putira chidimbu chepombi nechepamusoro pefurasiki, kuitira kuti hafu yetepi igare pamusoro pemuromo uye inobatsira kuisa plaster kubva pakutubuka.

Bvumira mold yekudyara kuti igadzikane. Tevedza mirairo chaiyo uye nguva yekuomesa yepurasita yako musanganiswa usati waenderera mberi. Kana wapedza, bvisa tepi uye uparadze chero plaster yakawandisa kubva pamusoro peforoma.

5) Isa furasiki yose mumoto wakagadzirirwa kusvika ku1300 degrees F (600 degrees C). Cherechedza, mapurasita akasiyana anogona kunge aine tembiricha dzakasiyana. Nekudaro, iwe haufanirwe kunge uri pane chero chinhu chiri pasi pe1100. Izvi zvinoomesa mold uye kunyungudutsa wakisi, zvichisiya kamuri isina mhango pakati peiyo yakakandwa jewelry mold.

Izvi zvinogona kutora kusvika maawa gumi nemaviri.

Kana uine honi yemagetsi, edza kuiisa kuti iwedzere kutonhora zvishoma nezvishoma kusvika 1300. Izvi zvinogona kubatsira kudzivirira kuputika.

6) Bvisa flask kubva muchoto uchipisa, uye tarisa pasi pemuumbi wezvipingamupinyi. Ita shuwa kuti wakisi inopisa inogona kubuda nyore kubva muforoma, uye kuti hapana chinoitadzisa. Kana pasina chinhu munzira, zunza furasiki zvinyoronyoro kuti uone kuti wakisi yese yabuda. Panofanira kuva nedhamu rewakisi mudura refurasiki kana kuti pasi pechoto.

Ita shuwa kuti wakapfeka magirovhosi ekuchengetedza uye magirazi.

3. Kukanda Zvishongo

1) Isa simbi yako yesarudzo mudururira crucible, wozonyungudusa mukati meiyo foundry. Tembiricha yekunyunguduka uye nguva ichatemwa nerudzi rwesimbi yauri kushandisa. Iwe unogona zvakare kushandisa blow-torch uye diki crucible kunyungudutsa sirivha yako. Uku ndiko kudira ruoko rwemhando yekukanda kune diki kugadzira chinangwa.

2) Shandisa jeweler's vacuum type casting (Vacuum Pressure Casting Machine) kudira simbi muforoma. Nezvishongo zvehunyanzvi, iwe unozoda vacuum mhando yekukanda muchina ine inert gasi kudzivirira. Izvi zvakafanana zvinogovera simbi nekukurumidza, asi haisi iyo yega sarudzo yaunayo yekukanda. Iyo yakanyanya kirasi, mhinduro iri nyore ndeyekungodira simbi nekuchenjera mugero rakasiiwa nepasi pe mold.

Iwe unogona kushandisa sirinji hombe, yesimbi-chaiyo kupomba simbi muforoma zvakare.

3) Bvumira simbi kuti itonhorere kwemaminitsi mashanu-10, wozoinyudza zvishoma nezvishoma mumvura inotonhora. Nguva yenguva inoda kutonhora inotsamira, hongu, pane simbi yakanyungudutswa uye inoshandiswa. Kurumidza kunyura uye simbi inogona kutsemuka-inononoka kunyura uye zvichange zvakaoma kubvisa plaster yese kubva musimbi yakaoma.

Tarisa nguva dzekutonhora kwesimbi yako usati waenderera mberi. Izvozvo zvakati, kana iwe uri mumucheka unogona kungomirira maminetsi gumi uye wobva wanyura mumvura inotonhora.

Iyo plaster inofanira kutanga kunyungudika paunenge uchiizunza ichitenderedza mvura inotonhora.

4) Tokonya mold zvinyoro nyoro nesando kuti ubvise chero plaster yakawandisa uye uratidze zvishongo. Kuparadzanisa flask kubva pachigadziko chesprue uye shandisa zvigunwe zvako kana bhurashi remazino kuti ubvise chero chekupedzisira chakanamira kune zvishongo.

4. Kupedza Zvishongo Zvako

1)Shandisa kona yeguyo ine vhiri rekucheka-cheka kucheka chero mitsetse yesimbi kubva kune sprues. Cheka zvidimbu zvitete zvesimbi zvawaida kugadzira gomba rekudira simbi. Chikuya chinobatwa nemaoko chinofanira kunge chakasimba zvakakwana.

2)Fungidzira uye kugeza asidhi kana kugeza kuti uchenese chero chidimbu chekupedzisira chepurasita. Kupfurwa kunowanzosiya simbi yakasviba uye yakasviba kutarisa. Iwe unogona kutarisa mune chaiwo washes kune mamwe masimbi, izvo zvinozotungamira kune zvakanyanya kupenya uye basa riri nyore kuchenesa chidimbu gare gare.

3) Bvisa chero zvisizvo pachidimbu chezvishongo uchishandisa simbi inoputika vhiri. Shandisa mafaera, zvipfeko zveenamel, polishes, nezvimwe kuchenesa chidimbu kusvika kune yako yaunoda maitiro. Kana iwe wakaronga kuisa dombo, zviite mushure mekunge wapedza kupukuta.