Inoramba ichikanda Michina

Iyo basa musimboti weyakajairika mhando inoenderera mberi yekukanda michina yakavakirwa pamazano akafanana seyedu vacuum pressure yekukanda michina. Panzvimbo pekuzadza iyo mvura muflask unogona kugadzira / kudhirowa pepa, waya, tsvimbo, kana chubhu uchishandisa graphite mold. Zvese izvi zvinoitika pasina mabhuru emhepo kana kupera porosity. Iyo vacuum uye yakakwira vacuum inoenderera yekukanda michina inonyanya kushandiswa kugadzira yakakwirira-yekupedzisira mhando waya senge bonding waya, semiconductor, aerospace munda.

-

Hasung-Yakakwirira Vacuum Inoenderera Kukandira Equipment YeMasimbi Akakosha

Masimbi anoshanda:zvinhu zvesimbi zvakaita segoridhe, K goridhe, sirivha, mhangura, uye alloys yavo

Maindasitiri ekushandisa:bonding wire materials, jewelry casting, precious metal processing, mayunivhesiti marabhoritari nezvimwe zvine chekuita neminda

Product zvakanakira:

1. High vacuum (6.67 × 10-3pa), high vacuum melting, high product density, low oxygen content, pasina pores, yakakodzera kubudisa tambo yepamusoro yekubatanidza;

2. Anti oxidation, inert gasi kudzivirira kunatsa, kugadzirisa dambudziko realloy oxidation;

3. Uniform ruvara, electromagnetic uye yemuviri inomutsa nzira dzinoita kuti alloy ruvara ruwedzere kufanana;

4. Chigadzirwa chakapedzwa chine nzvimbo yakatsetseka uye inotora dhizaini yekukwevera pasi. Iro vhiri rekukwevera rakave nekurapwa kwakakosha, uye chigadzirwa chakapedzwa hachina kukuvadzwa kwepamusoro uye nzvimbo yakatsetseka;

5. Kudzora tembiricha chaiyo ± 1 ℃, uchishandisa mamita ekudzora tembiricha kubva kunze kwenyika uye yakangwara PID yekudzora tembiricha system, ine musiyano wetembiricha we± 1 ℃;

6. 7-inch full-color touch screen, zviri nyore kuona / kubata, itsva system, nyore UI interface, nyore kushanda nekubata kamwe chete;

7. Kudzivirirwa kwakawanda, kuchengetedzwa kwakawanda kwekuchengetedza, kunetseka kusununguka kushandiswa

-

Masimbi Anokosha Horizontal Vacuum Continous Casting Machine

Horizontal vacuum inoenderera mberi ichikanda muchina Zvakanakira

1. Kuvandudza chigadzirwa chemhando

2. Kuvandudza maitiro ekutonga

3. Kuwedzera Kubudirira

4. Kushanda kwesimba

Hunhu hwehorizontal vacuum inoramba ichikanda muchina

1. Horizontal Casting Design

2. Vacuum Chamber

3. Kutonhora system

4. Automation uye control system

5. Kunyungudika kukuru

6. Yakanaka yemhando yekukanda chigadzirwa

-

Unoramba Uchikanda Muchina weGoridhe Silver Copper Alloy 20kg 30kg 50kg 100kg

1.Pakarepo sirivha yegoridhe strip waya chubhu tsvimboinoenderera mberi ichikanda muchinanokuti zvishongo zvakatangwa pamusika, yakagamuchira mhinduro yakanaka kubva kune vatengi vakawanda, avo vakati rudzi urwu rwechigadzirwa runogona kugadzirisa zvinobudirira zvavanoda.Uyezve, chigadzirwa chacho chinoshandiswa zvakanyanya muMetal Casting.

2.Inoenderera mberi Casting Machine yeKugadzira Rod Strip Pipe ine 20kg 30kg 50kg 100kg kana ichienzaniswa neyakafanana zvigadzirwa pamusika, ine zvisingaenzaniswi zvakatanhamara zvakanakira maererano nekuita, mhando, chitarisiko, nezvimwewo, uye inonakidzwa nemukurumbira wakanaka mumusika.Hasung inopfupikisa kukanganisa kwezvigadzirwa zvekare, uye inoramba ichivandudza. Izvo zvinotsanangurwa zveUnoramba Uchikanda Muchina weKugadzira Rod Strip Pipe ine 20kg 30kg 50kg 100kg inogona kugadzirwa zvinoenderana nezvaunoda.

-

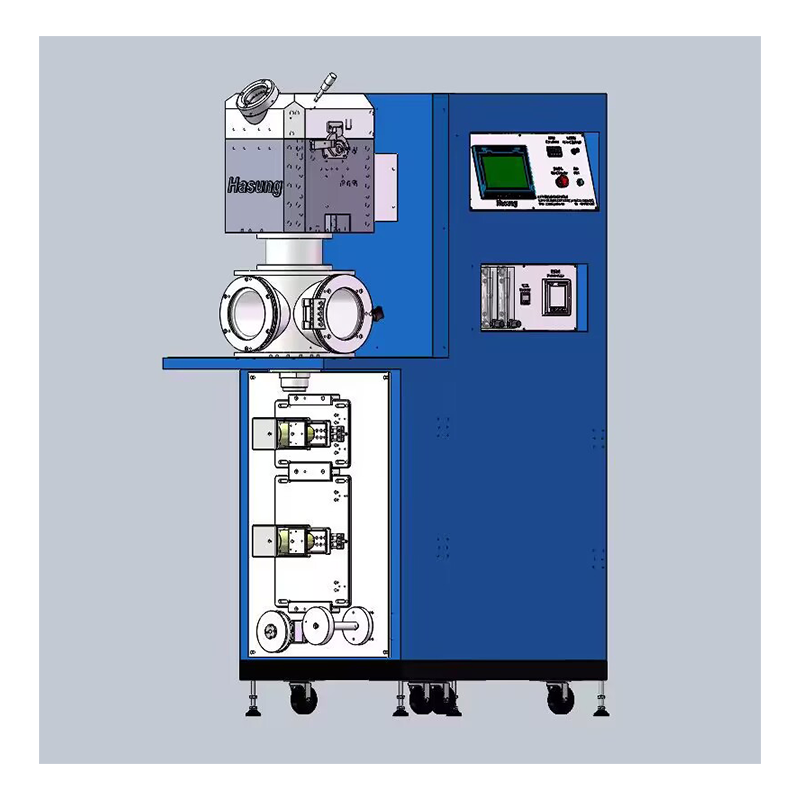

Yakakwira Vacuum Inoenderera Inokanda Muchina YeZvishandiso Zvitsva Kukanda Bonding Goridhe Silver Copper Wire

Kukandwa kwezvinhu zvemagetsi senge bond alloy sirivheri waya yemhangura uye yakakwirira-kuchena yakakosha waya Dhizaini yegadziriro yemidziyo iyi inobva pane izvo chaizvo zvinodiwa zvepurojekiti uye maitiro, uye inoshandisa zvizere tekinoroji yemazuva ano yepamusoro-soro.

1. Adopt German high-frequency heat technology, automatic frequency tracking uye teknolojia yekudzivirira yakawanda, inogona kunyunguduka munguva pfupi, kuchengetedza simba uye kushanda zvakanaka.

2. Iyo yakavharwa mhando + inert gasi kudzivirira kunyunguduka kamuri inogona kudzivirira oxidation yezvinhu zvakanyungudutswa zvakasvibiswa uye kusanganiswa kwetsvina. Mudziyo uyu wakakodzera kukandwa kwepamusoro-kuchena simbi zvinhu kana nyore oxidized elemental simbi.

3. Shandisa yakavharwa + inert gasi kuchengetedza kamuri inonyunguduka. Kana ichinyunguduka mune inert gasi nharaunda, iyo oxidation kurasikirwa kwekabhoni mold kunenge kusingaite.

4. Nekushanda kwe electromagnetic inokurudzira + mechanical inokurudzira pasi pekuchengetedzwa kwegasi inert, hapana kuparadzaniswa kwemavara.

5. Kushandisa Mistake Proofing (anti-fool) automatic control system, kushanda kunowedzera nyore.

6. Uchishandisa PID tembiricha control system, tembiricha yakanyatsojeka (± 1 ° C).

7. HVCC yakatevedzana yakakwira vacuum inoramba ichikanda michina inogadzirwa yakazvimiririra uye inogadzirwa, ine tekinoroji yepamusoro, inoshandiswa kuramba ichikandwa yegoridhe rakachena, sirivha, mhangura nemamwe maalloys.

8. Ichi chishandiso chinoshandisa Mitsubishi PLC chirongwa chekudzora hurongwa, SMC pneumatic uye Panasonic servo mota drive uye zvimwe zvemukati uye zvekunze mhando zvikamu.

9. Kunyunguduka mukamuri yakavharwa + inert gasi yekudzivirira yakanyunguduka, kudyisa kaviri, electromagnetic kubvongodza, mechanical kubvongodza, firiji, kuitira kuti chigadzirwa chive neunhu husina oxidation, kurasikirwa kwakaderera, kusina porosity, kusarura kwemavara, uye kutaridzika kwakanaka.

10. Vacuum Type: High vacuum.

-

Vacuum Inoenderera Inokanda Muchina weGoridhe Silver Copper Alloy

Yakasarudzika vacuum inoramba ichikanda system

Kune yemhando yepamusoro yesemi-akapedza zvinhu:

Kuti tideredze njodzi yeoxidation panguva yekunyunguduka uye panguva yekudhirowa, isu tinotarisisa kudzivirira kusangana neokisijeni uye nekudzikisira nekukurumidza kwekushisa kwesimbi yakadhonzwa.

Zvimiro zvekudzivisa kusangana neokisijeni:

1. Inert gasi system yekamuri yekunyungudika

2. Vacuum system yekamuri yekunyunguduka - yakasarudzika inowanikwa yeHasung vacuum inoramba ichikanda michina (VCC yakatevedzana)

3. Inert gasi ichitsvaira pafa

4. Optical die tembiricha kuyerwa

5. Yekuwedzera yechipiri kutonhora system

6. Zvose izvi zviyero zvakakosha kunyanya kune alloys ane mhangura segoridhe tsvuku kana sirivha sezvo zvinhu izvi zvinowanzoita oxidise nyore.Kudhirowa maitiro uye mamiriro ezvinhu zvinogona kucherechedzwa nyore nekutarisa mahwindo.

Vacuum madhigirii anogona kunge ari maererano nechikumbiro chevatengi.

-

Unoramba Uchikanda Muchina weGoridhe Silver Copper Alloy

Dhizaini yegadziriro iyi yemidziyo inobva pane izvo chaizvo zvinodiwa zveprojekiti uye maitiro, uchishandisa yemazuva ano yepamusoro-tech tekinoroji.

1. Kushandisa German high-frequency heat technology, automatic frequency tracking uye multiple protection technologies, inogona kunyungudutswa munguva pfupi, kuchengetedza simba nekuchengetedzwa kwezvakatipoteredza, uye kushanda kwepamusoro kwekushanda.

2. Iyo yakavharwa mhando + inert gasi kudzivirira kunyunguduka kamuri inogona kudzivirira oxidation yezvinhu zvakanyungudutswa zvakasvibiswa uye kudzivirira kusanganiswa kwetsvina. Mudziyo uyu wakakodzera kukandwa kwepamusoro-kuchena simbi zvinhu kana nyore oxidized elemental simbi.

3. Kushandisa yakavharwa + inert gasi kudzivirira kunyunguduka kamuri, kunyunguduka uye vacuuming kunoitwa panguva imwe chete, nguva iri hafu, uye kubudirira kwekugadzira kunovandudzwa zvikuru.

4. Kunyunguduka mune inert gasi nharaunda, iyo oxidation kurasikirwa kwekabhoni crucible inenge isingakoshi.

5. Ne electromagnetic inokurudzira basa pasi pekuchengetedzwa kwegasi inert, hapana kupatsanurwa kwemavara.

6. Inotora Mistake Proofing (anti-fool) automatic control system, iyo iri nyore kushandisa.

7. Uchishandisa PID tembiricha control system, tembiricha yakanyatsojeka (± 1 ° C). Iyo HS-CC yakatevedzana inoenderera mberi yekukanda michina inogadzirwa yakazvimiririra uye inogadzirwa nehunyanzvi hwepamusoro uye yakatsaurirwa kunyungudusa nekukanda goridhe, sirivheri, mhangura uye mamwe alloys mitsetse, tsvimbo, mashiti, mapaipi, nezvimwe.

8. Iyi midziyo inoshandisa Mitsubishi PLC program control system, SMC pneumatic uye Panasonic servo motor drive uye zvimwe zvinonyatsozivikanwa zvemhando yemhando kumba nekune dzimwe nyika.

9. Kunyunguduka, electromagnetic inokurudzira, uye firiji mukamuri yakavharwa + inert gasi yekudzivirira yakanyunguduka, kuitira kuti chigadzirwa chive neunhu hwekusava neoxidation, kurasikirwa kwakaderera, kusina pores, kusaparadzana kwemavara, uye kutaridzika kwakanaka.

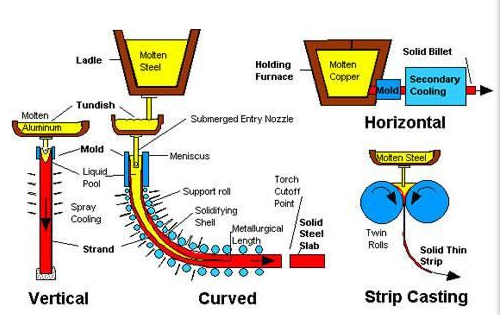

Chii chinonzi continuous casting, ndechei, chii chakanakira?

Iyo inoenderera mberi yekukanda maitiro inzira inoshanda kwazvo yekugadzira zvigadzirwa zvakapera semi-apera senge mabara, profiles, slabs, mitsetse uye machubhu akagadzirwa kubva kugoridhe, sirivheri uye asiri-ferrous simbi semhangura, aluminium uye alloys.

Kunyangwe paine akasiyana anoenderera mberi ekukanda maitiro, hapana mutsauko wakakosha mukukanda goridhe, sirivha, mhangura kana alloys. Musiyano wakakosha ndiwo tembiricha yekukanda iyo inotangira pa1000 ° C kana iri sirivheri kana mhangura kusvika 1100 ° C kana iri goridhe kana mamwe maalloys. Simbi yakanyungudutswa inoramba ichikandwa mumudziyo wekuchengetera unodaidzwa kuti ladle uye inoyerera ichibva ipapo ichienda kune yakatwasuka kana yakachinjika yekukanda mold ine magumo akashama. Ichiri kuyerera nepakati peforoma, iyo yakatonhodzwa necrystallizer, iyo mvura yakawanda inotora chimiro cheforoma, inotanga kusimba pamusoro payo uye ichisiya mold iri semi-yakasimba tambo. Panguva imwe chete, kunyungudika kutsva kunogara kuchipihwa kune mold pamwero wakafanana kuti uenderane netambo inosimbisa ichisiya mold. Iyo tambo inowedzera kutonhodzwa nenzira yemvura yekupfapfaidza system. Kuburikidza nekushandiswa kwekutonhora kwakawedzera zvinokwanisika kuwedzera kukurumidza kwekristallisation uye kugadzira mune strand homogeneous, yakanaka-grained chimiro chinopa semi-yakapedza chigadzirwa yakanaka tekinoroji zvivakwa. Iyo tambo yakaomeswa inozotwasanudzwa uye ichichekwa kusvika pahurefu hwaidiwa neshears kana mwenje wekucheka.

Zvikamu zvinogona kushandirwazve mune zvinotevera-in-line rolling Operations kuti uwane mabara, tsvimbo, extrusion billets (blanks), slabs kana zvimwe zvigadzirwa zvakapedzwa muzvikamu zvakasiyana.

Nhoroondo yekuramba ichikanda

Kuedza kwekutanga kukanda simbi nenzira inopfuurira kwakaitwa pakati pezana ramakore rechi 19. Mugore ra1857, Sir Henry Bessemer (1813-1898) vakagashira patent yekukanda simbi pakati pemaroller maviri anotenderera ekugadzira simbi slabs. Asi panguva iyoyo nzira iyi yakaramba isina hanya. Kufambira mberi kwakasimba kwakaitwa kubva 1930 zvichienda mberi neiyo Junghans-Rossi tekinoroji yekuramba ichikanda mwenje uye simbi inorema. Nezvesimbi, iyo inoenderera mberi yekukanda maitiro akagadzirwa muna 1950, pamberi (uye zvakare mushure) iyo simbi yakadirwa muchimiro chakamira kuita 'ingots'.

Kuramba kuchikandwa kwetsvimbo isiri-ferrous yakagadzirwa neProperzi process, yakagadzirwa naIlario Properzi (1897-1976), muvambi wekambani yeContinuus-Properzi.

Zvakanakira kuramba uchikanda

Kuenderera mberi kukanda ndiyo nzira yakakwana yekugadzira zvigadzirwa zvehafu-yakapedzwa zvehukuru hurefu uye inogonesa kugadzirwa kweakawanda mukati menguva pfupi. Iyo microstructure yezvigadzirwa yakaenzana. Kuenzaniswa nekukanda muforoma, kuenderera mberi kukanda kune hupfumi maererano nekushandiswa kwesimba uye kunoderedza zvimedu zvishoma. Uyezve, zvinhu zvezvigadzirwa zvinogona kuchinjwa nyore nyore nekushandura mapeji ekukanda. Sezvo mabasa ese achigona kuve otomatiki uye achidzorwa, kuenderera mberi kukanda kunopa akawanda mikana yekuchinjika kugadzirwa uye nekukurumidza kuchinja musika zvinodiwa uye kuisanganisa nedigitization (Industrie 4.0) matekinoroji.