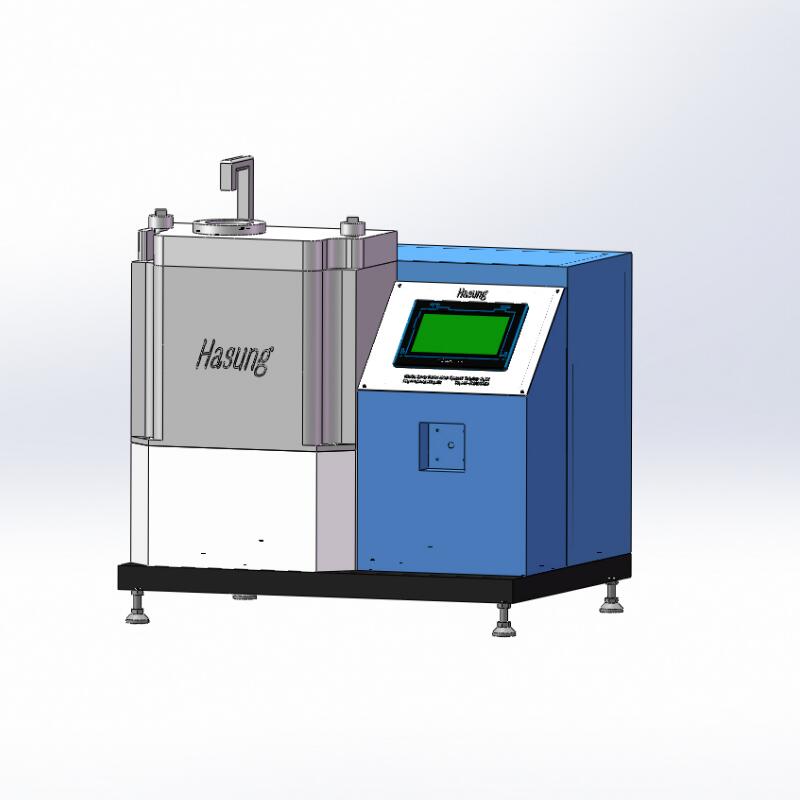

4 Bhawa 1kg Automatic Gold Bar Kugadzira Machine Hasung

Technical Parameters

| Muenzaniso Nha. | HS-GV4 | HS-GV15 | HS-GV30 | ||

| Otomatiki Kuvhura Kavha Goridhe Bar Vacuum Casting Machine | |||||

| Magetsi | 380V ,50/60Hz | ||||

| Power Input | 50KW | 60KW | 70KW | ||

| Max Temp | 1500°C | ||||

| Yakawanda Yekukanda Nguva | 10-12mins. | 12-15mins. | 15-20mins. | ||

| Shielding Gasi | Argon / Nitrogen | ||||

| Purogiramu yemabhawa akasiyana | Available | ||||

| Capacity | 4kg: 4 pcs 1kg, 8pcs 0.5kg kana kupfuura. | 15kg: 1pcs 15kg, kana 5pcs 2kg kana kupfuura | 30kg: 1pcs 30kg, kana 2pcs 15kg kana kupfuura | ||

| Application | Ndarama, Silver, Platinum, Palladium (Apo nePt, Pd, yakagadzirirwa) | ||||

| Vacuum Pombi | Yemhando yepamusoro vacuum pombi (inosanganisirwa) | ||||

| Operation nzira | Imwe-kiyi oparesheni yekupedzisa hurongwa hwese, POKA YOKE foolproof system | ||||

| Kudzora system | 10" Weinview / Siemens PLC +Munhu-muchina interface yakangwara control system (optional) | ||||

| Kutonhora mhando | Mvura inotonhorera (inotengeswa zvakasiyana) kana Mvura inomhanya | ||||

| Dimensions | 1460*720*1010mm | 1460*720*1010mm | 1530x730x1150mm | ||

| Kurema | 300KG | 300KG | 400KG | ||

Nhanganyaya yeHasung Gold Bar Vacuum Casting Machine - Iyo Yekupedzisira Mhinduro Yemhando yepamusoro Goridhe uye Sirivha Bhara.

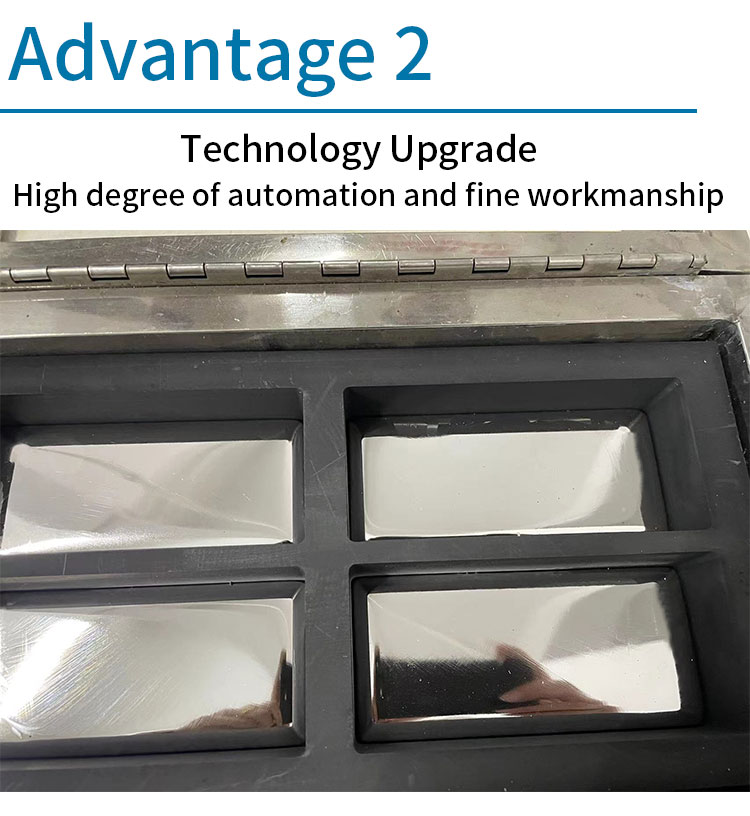

Uri kutsvaga mhinduro dzakavimbika, dzinoshanda dzekugadzira goridhe remhando yepamusoro uye sirivheri mabara? Goridhe bar vacuum yekukanda muchina ndiyo sarudzo yako yakanaka. Iyi midziyo yemazuva ano yakagadzirirwa kusangana nezvinodiwa zvevatangi vekutanga uye nyanzvi dzine ruzivo muindasitiri yesimbi yakakosha. Nekushanda kwayo otomatiki uye kugona kunyungudika nekukurumidza, muchina uyu ndiyo sarudzo yakanaka kune avo vari kutsvaga mibairo yakanaka zviri nyore uye nemazvo.

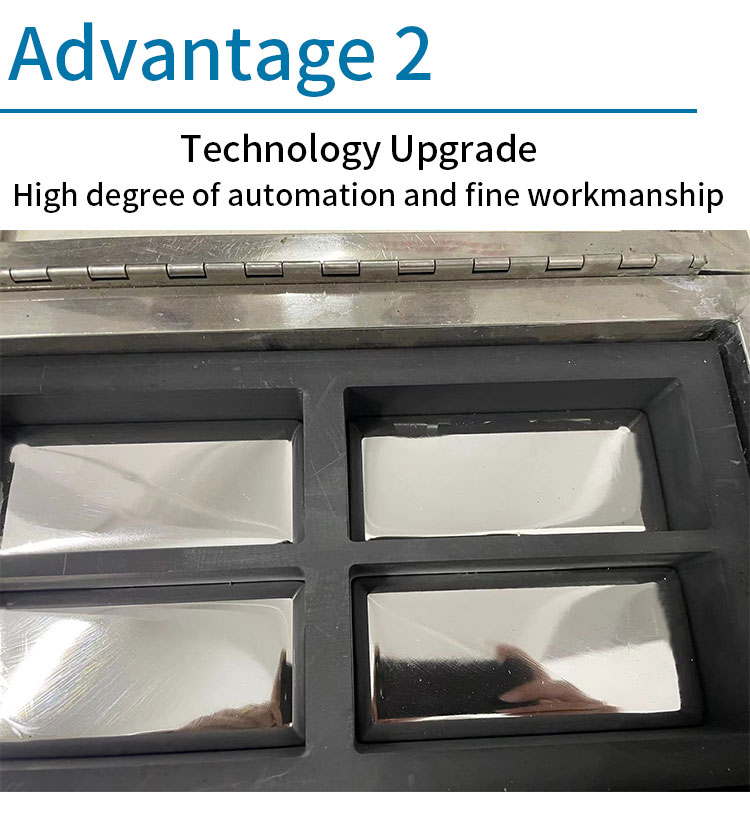

Goridhe bar vacuum yekukanda michina inogadzirwa neazvino tekinoroji kuti ipe isina musono uye mushandisi-ane hushamwari ruzivo. Kushanda kwayo kwakazara otomatiki kunoita kuti ive yakanaka kune vanotanga vachangotanga muindasitiri. Intuitive kudzora uye nyore-kutevera mirairo inovimbisa kuti kunyangwe avo vane ruzivo rushoma vanogona kushandisa muchina nekuvimba uye kuwana mibairo yepamusoro.

Chimwe chezvinhu zvakatanhamara zvegoridhe bar vacuum casting machines kugona kwavo kugadzira goridhe nesirivha mabara emhando yepamusoro. Kunyangwe iwe uchida kugadzira yekudyara-giredhi goridhe nesirivheri kana yakanaka zvishongo zvinhu, muchina uyu unopa mhedzisiro yakakwana nguva dzese. Precision engineering uye advanced vacuum casting tekinoroji inovimbisa kuti mabara anogadzirwa haana tsvina uye hurema uye anosangana neakaomesesa emhando zviyero.

Pamusoro peiyo yakasarudzika mhando yekubuda, goridhe bar vacuum yekukanda michina inozivikanwa zvakare nekukasira kunyungudika kugona. Muindasitiri yesimbi yakakosha, nguva ndeye musimboti uye muchina uyu wakagadzirirwa kukwenenzvera maitiro ekugadzira. Nenguva dzinokurumidza kunyungudika, unogona kuwedzera zvakanyanya kushanda zvakanaka kwekugadzira uye kusangana nezvinodiwa zvemusika unokurumidza kukurumidza pasina kukanganisa kunaka kwechigadzirwa chekupedzisira.

Uye zvakare, goridhe bar vacuum yekukanda michina inovakwa kuti igare uye inotarisa pakusimba uye kuvimbika. Kuvakwa kwayo kwakasimba uye zvemhando yepamusoro zvinhu zvinoita kuti ikwanise kumirisana nekuoma kwekuenderera mberi kwekushandisa, zvichiita kuti ive smart investimendi yebhizinesi rako. Nekugadzirisa kwakaringana, muchina uyu ucharamba uchipa kuita kwakanakisa kwemakore anotevera, uchikupa yakavimbika, inoshanda yekugadzira mhinduro.

Ungave uri mhizha diki kana mugadziri muhombe, goridhe bar vacuum yekukanda michina inopa chiyero chakakwana chechokwadi, kumhanya uye nyore kushandisa. Hurukuro hwayo hunoita kuti ive yakakodzera kushandiswa kwakasiyana-siyana, kubva pakugadzira mabhara egoridhe akagadzirwa netsika kusvika pakugadzira mbariro dzegoridhe dzakamira. Hazvina mhosva kuti zvaunoda kugadzira ndezvipi, muchina uyu unogona kusangana nekupfuura zvaunotarisira.

Zvese mune zvese, goridhe bar vacuum yekukanda michina ndiyo yekupedzisira mhinduro kune avo vari kutsvaga kugadzira emhando yepamusoro goridhe nesirivha mabara zviri nyore uye nemazvo. Kushanda kwayo kwakazara otomatiki, kugona kunyungudika nekukurumidza uye kuburitsa kwemhando yepamusoro kunoita kuti ive chinhu chakakosha kune chero bhizinesi muindasitiri yesimbi yakakosha. Chengetedza mari mumuchina uyu wekucheka-kumucheto kuti utore kugona kwako kugadzira kune hurefu hutsva. Sangana nemusiyano wegoridhe bar vacuum yekukanda muchina unogona kuunza kubhizinesi rako.

Product Display

Title: Iyo yakaoma maitiro ekunatsa goridhe uye kukanda ingot muindasitiri

Munyika yematare anokosha, ndarama inobata nzvimbo inokosha. Kukwezva kwayo uye kukosha kwayo kwakaita kuti ive chinhu chinotsvakwa kwemazana emakore, uye indasitiri yekunatsa goridhe inoita basa rakakosha mukuona kuti goridhe ratinoshandisa muzvishongo, zvemagetsi nekudyara rinosangana nemhando yepamusoro yekuchena uye kunaka kwekuita. Chinhu chakakosha cheindastiri iyi igold ingot casting process, iyo inoshandura goridhe rakanatswa kuita masimbi egoridhe anofananidzira hupfumi nebudiriro. Mubhuku rino, tichaongorora maitiro akaomarara ekunatsa nekukanda goridhe, tichiburitsa nhanho dzakadzama dzakabatanidzwa uye kukosha kwemaitiro aya muindasitiri yegoridhe.

Kuchenesa kwegoridhe: kubva kune ore kuenda kugoridhe rakazara

Rwendo rwegoridhe kubva pachimiro chayo mbishi sesimbi kupinda musimbi inopenya yatinochiva rinotanga nekunatsa goridhe. Iyi nzira yakaoma inosanganisira matanho akati wandei, rimwe nerimwe rakanangana nekubvisa tsvina uye kuwana nhanho inodiwa yekuchena. Danho rekutanga pakunatsa goridhe nderokubvisa goridhe kubva pasi, wobva waripwanya nekukuya kuita upfu hwakatsetseka. Hupfu uhu hunozopinda nemunhevedzano yemakemikari nemaitiro emuviri anopatsanura goridhe kubva kune mamwe mamineral netsvina.

Imwe yedzakajairika nzira dzekunatsa goridhe kushandisa cyanide leaching, apo mushonga wecyanide unoiswa kune goridhe kunyungudutsa goridhe. Mushonga unobva waitwa kuti udzore goridhe, iro rinoramba richicheneswa kuburikidza nemaitiro akadai sekunyungudusa uye electrolysis. Maitiro aya anosanganisira kushandisa tembiricha yakakwira uye kuita kwemakemikari kubvisa chero tsvina yasara, zvichikonzera goridhe rakachena rinosangana nekuchena kweindasitiri.

Kukosha Kwekuchena muKunatsa Goridhe

Kuchena chinhu chakakosha mukunatswa kwegoridhe sezvo inobata zvakananga kukosha uye kunaka kwechigadzirwa chekupedzisira. Kuchena kwegoridhe kunoyerwa mumakarati, iine 24-karat goridhe riri iro rakachena uye rine 99.9% yegoridhe. Iyo yakaderera kukosha kwekarati, kuderera kwegoridhe. Semuenzaniso, 18 karat goridhe ine 75% yegoridhe uye 25% mamwe masimbi. Kuwana kuchena kwepamusoro kwakakosha kuti usangane nezvinoda kuomesesa zvemaindasitiri anovimba negoridhe, sekugadzira zvishongo nekugadzirwa kwemagetsi.

Pamusoro pekusangana nezviyero zvehutsanana, kunatsa goridhe kunoitawo basa rakakosha mukuona maitiro ehunhu uye anoenderera mberi mukati meindasitiri. Maitiro ekunatsa goridhe ane mutoro anosanganisira kushandiswa kwemaitiro anoenderana nemhoteredzo uye kuitwa kwemaitiro akanaka evashandi anogadzirisa matambudziko ane chekuita nemhoteredzo nemagariro ekucherwa kwegoridhe nekunatsa mabasa.

Goridhe Ingot Casting: Shandura goridhe rakanatswa kuita mbariro dzegoridhe

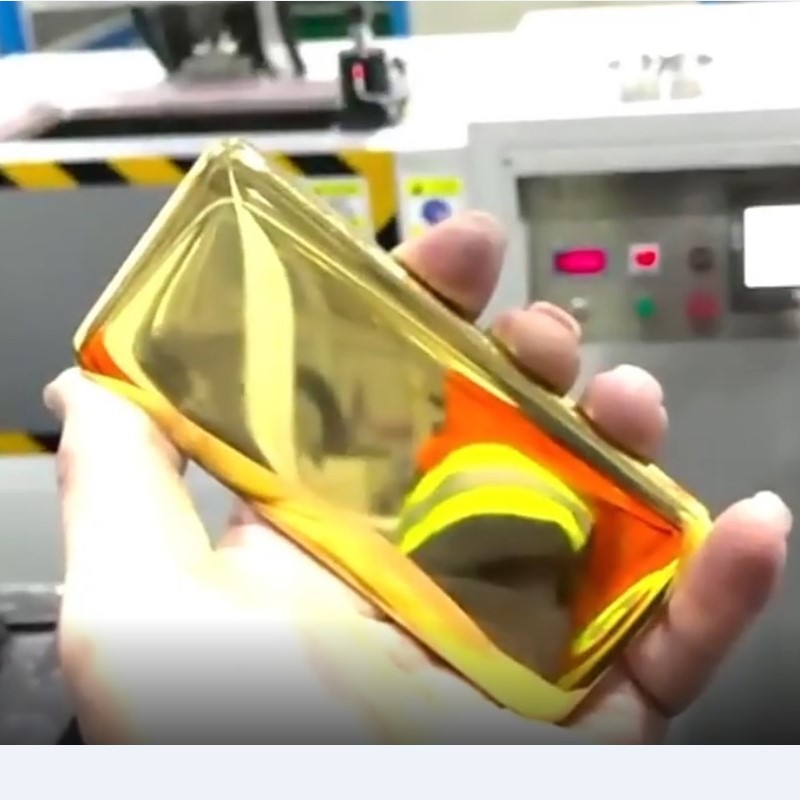

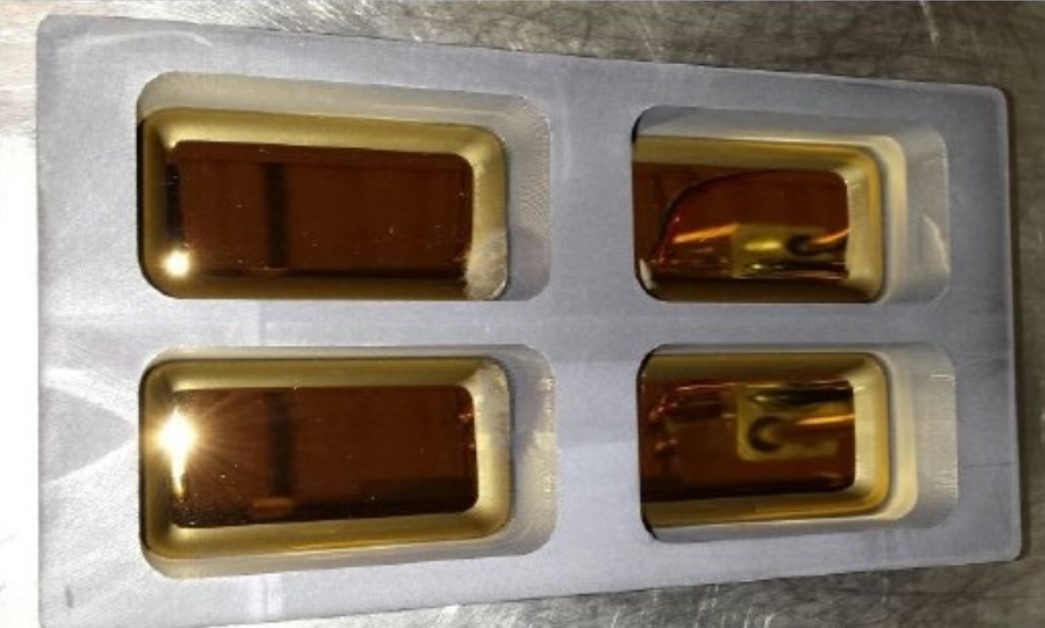

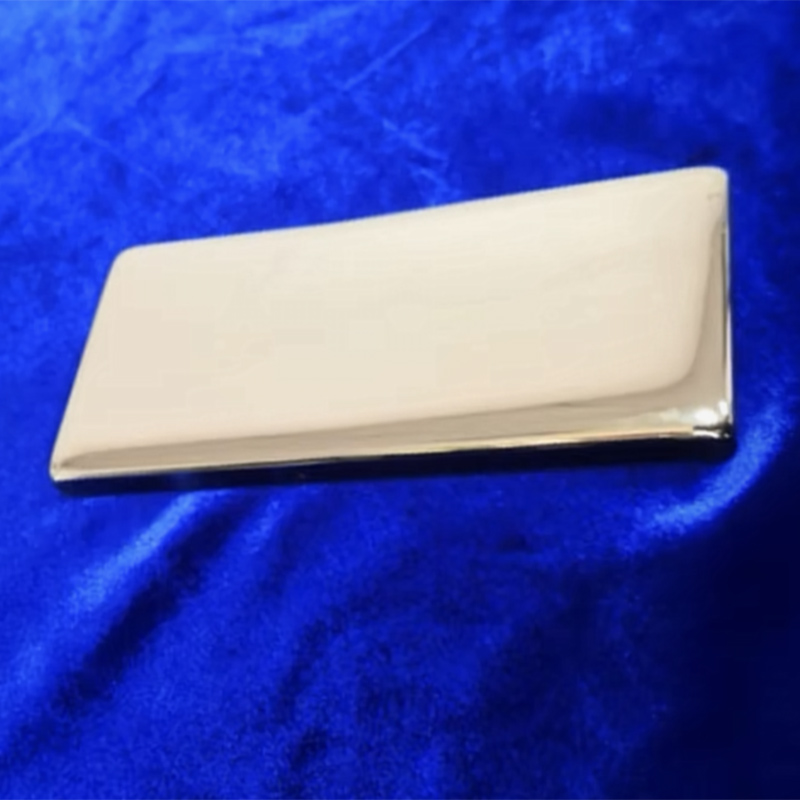

Kana goridhe ranatswa kusvika pakuchena kwaunoda, rinogona kushandurwa kuita mabhara egoridhe anozivikanwa segoridhe ingots. Maitiro ekukanda ingot yegoridhe anosanganisira kudururira goridhe rakanyungudutswa mu mold kuti vaumbe masimbi egoridhe akasimba, iri nyore uye yakamisikidzwa nzira yekutengesa nekuchengetedza. Iyi nzira inoda kurongeka uye hunyanzvi hwekuona kuti ingot inoguma inosangana nezvinodiwa maererano nehuremu, ukuru uye kuchena.

Nhanho yekutanga mukukanda ingot yegoridhe ndeyekugadzirira mold, iyo inowanzogadzirwa kubva kune yakasimba zvinhu senge graphite kana simbi. Mould inogadzirwa kuti ibudise ingo dzegoridhe dzehuremu chaihwo uye hukuru, dzine mavara anoratidza kuchena uye kwakabva goridhe. Kana mold yagadzirwa, goridhe rakanatswa rinonyungudutswa pakupisa kwakanyanya mucrucible, kazhinji uchishandisa choto chekupinza kana zvimwe hunyanzvi.

Ndarama yakanyungudutswa inozonyatsodirwa muforoma, chiito chinoda hunyanzvi uye kutarisisa kune zvakadzama kudzivirira chero kukanganisa kana kusarongeka mune yekupedzisira ingot yegoridhe. Mushure mekunge goridhe raoma, mold inovhurwa kuratidza ingot yegoridhe ichangobva kunambwa, iyo inozoongororwa yoiswa chiratidzo kuratidza kuchena kwayo uye chokwadi. Aya mavara anowanzo sanganisira huremu, kuchena uye chiratidzo chekambani yekunatsa, ichipa ruzivo rwakakosha kune vatengi nevatengesi mumusika wegoridhe.

Kukosha kwekukandira ingot yegoridhe muindasitiri

Kukandwa kwegoridhe ingot chinhu chakakosha pakati penzira yekunatsa goridhe nemusika wegoridhe, ichipa chimiro chakamisikidzwa uye chinozivikanwa chekutengesa nekuchengetedza goridhe. Aya mabhawa egoridhe anoshandiswa zvakanyanya mukutsvaga mari pamwe nekugadzira zvishongo nezvimwe zvigadzirwa zvegoridhe. Iyo inochenjerera ingot yekukanda maitiro inova nechokwadi chekuti goridhe rinosangana nekuchena kunodiwa uye mhando zviyero, ichiisa chivimbo muvatengi uye vanoisa mari vanovimba nekuvimbika kwegoridhe ravanotenga.

Pamusoro pezvo, bullion yegoridhe inoita basa rakakosha mumusika wepasi rose wegoridhe senzira yepasirese yemari uye chitoro chekukosha. Huremu hwakaenzana hwegoridhe uye kuchena kunoita kuti ive yakanakira kutengeserana nedzimwe nyika nekudyara, kufambisa kutengeserana uye kuve chinhu chakavimbika munguva yekusagadzikana kwehupfumi. Iyo ingot casting process saka inobatsira kuwedzera mvura uye kugadzikana kwemusika wegoridhe, zvichibvumira kuchinjana kusina musono kwegoridhe kutenderera pasirese.

Remangwana rekunatsa goridhe nekukanda ingot

Sezvo kudiwa kwegoridhe kuri kuramba kuchikura, zvichikonzerwa nezvinhu zvakaita sekugadzikana kwehupfumi, hunyanzvi hwekuvandudza tekinoroji uye kukosha kwetsika, indasitiri yekunatsa goridhe ichaita basa rinowedzera kukosha mukuzadzisa ichi chinodikanwa. Kufambira mberi mukukwenenzvera tekinoroji uye maitiro anoenderera mberi anotarisirwa kuenderera mberi nekuvandudza kushanda uye kwezvakatipoteredza kukanganisa kwekuita goridhe kucheneswa, kuve nechokwadi chekuti indasitiri inosangana nemazinga epamusoro ehutsika uye ane mutoro.

Saizvozvowo, iyo goridhe ingot yekukanda maitiro ingangoramba ichivandudza nekuvandudza, iine tarisiro yekurongeka, otomatiki, uye kugadzirisa kuzadzisa zvinoshanduka zvinodikanwa zvemusika. Iko kushandiswa kwehunyanzvi hwekukanda matekiniki uye zvinhu zvinogona kuwedzera kunaka uye kuenderana kweingots dzegoridhe, nepo tekinoroji yedhijitari uye blockchain mhinduro dzinogona kushandura chitupa uye kuteedzera kwegoridhe ingots, ichipa pachena kune vatengi nevanoisa mari. uye kuchengeteka.

Mukupedzisa, kukwenenzvera kwegoridhe nekukanda ingot chikamu chakakosha cheindasitiri yegoridhe uye inosarudza kunaka, kukosha uye kutengeswa kwesimbi yakakosha iyi. Kubva pakunyatsobvisa tsvina panguva yekucheneswa kwegoridhe kusvika pakukandwa chaiko kweingots dzegoridhe, maitiro aya anoratidza hunyanzvi nehunyanzvi hweindasitiri yegoridhe. Sezvo indasitiri ichiramba ichishanduka uye ichienderana nekuchinja kwezvinodiwa uye mwero, hunyanzvi nesainzi yekunatsa nekukanda goridhe inoramba yakakosha kuitira kuti goridhe rirambe richikwezva uye kukosha munyika yanhasi.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

.png)