Powder Atomization Plants

Kuita Metal Powder

ThePodhaMetallurgy (PM) maitiro ari kugadzira simbi hupfu.

Iyo simbipoda mvura atomizerinoshandiswa kugadzira yakakwira mhando uye homogenous master zviyo uye alloy zviyo, uye zvakare hupfu, kutanga kubva kune yakabikwa zvinhu zvakanyungudutswa nekudziisa mumhepo inodzivirira, uyezve Pakukanda hupfu, ichatora pfuti yemvura yakadzvanywa kuti ipwanye yakanyungudutswa. simbi kuita chidimbu chakanakas. Kazhinji, inoshandiswa muindasitiri yekunatsa simbi.

The Gasi Atomizer iriinoratidzirwa nekusvibiswa kudiki kwezvakatipoteredza, dhigirii yakakwira yebhora-chimiro cheupfu, yakaderera okisijeni yemukati uye nekukurumidza kutonhora mwero uye zvichingodaro. Kuburikidza nemakore akawanda 'anogara achivandudza uye kuvandudza, kambani yedu yakagadziridza gasi atomization poda-yekugadzira tekinoroji uye tekinoroji kakawanda kuitira kugadzira simbi uye alloy poda yekushanda kwepamusoro. Parizvino, tekinoroji yave chinhu chinotungamira kutsigira nekusimudzira atomization poda-kugadzira michina, tsvakiridzo yezvinyorwa uye kuvandudza tekinoroji.

Nheyo yekushanda yeatomizing midziyo inoreva nzira yekugadzira hupfu inonyungudutsa simbi kana alloy pasi peimwe mamiriro ane simbi yemvura yakadururwa zvisingaite kuti kupisa kwekuchengetedza crucible ichiyerera ichibuda nemumuromo diversion yemvura (inodzika), uye inotora mukana weiyo yakanyanya kudzvanywa magasi emhino. kupwanya simbi yemvura muhuwandu hwehuwandu hwakanaka uye huduku hwemvura inodonha; Madonhwe emvura anobhururuka anoomesa kuita bhora-shape kana sub ball-shape particles uye nokudaro anopedzisa iyo yese yekugadzira hupfu.Kazhinji, inoshandiswa mune simbi 3D kudhinda indasitiri.

-

Metal Flakes Processing Machine Gold Flakes Kugadzira Equipment yeGoridhe Kunatsa

Equipment sumo:

1. Adopt medium frequency induction, nguva pfupi yekunyunguduka uye kushanda kwakanyanya.

2. Imba yakanyunguduka inoshandisa inert gasi iyo inoshandiswa kudzivirira oxidation yezvinhu zvesimbi uye kuiswa kwetsvina. Nechinangwa ichi, yakakodzera kune yakakwirira-kuchena simbi zvinhu kana kunyungudutswa ine nyore oxidized zvinhu.

3. Iyo mechanical inokurudzira basa pasi pevacuum state inogamuchirwa, uye kuumbwa kwemavara hakuna kuparadzaniswa.

4. Kunyunguduka kunodzivirirwa ne-high-purity inert gas, saka graphite ruthenium ine zvishoma zvishoma oxidation kurasikirwa.

5. Kushandisa Taiwan Weinview/Siemens PLC controller, kushanda kuri nyore.

6. Iyo mold inodziya yega panguva yekudurura kuti ive nechokwadi chekukanda.

7. Nezvizhinji zvepasi rose zvine mukurumbira mhando zvikamu zvekuve nechokwadi chemhando yepamusoro.8. Kazhinji inoshandiswa pakunatsa goridhe.

-

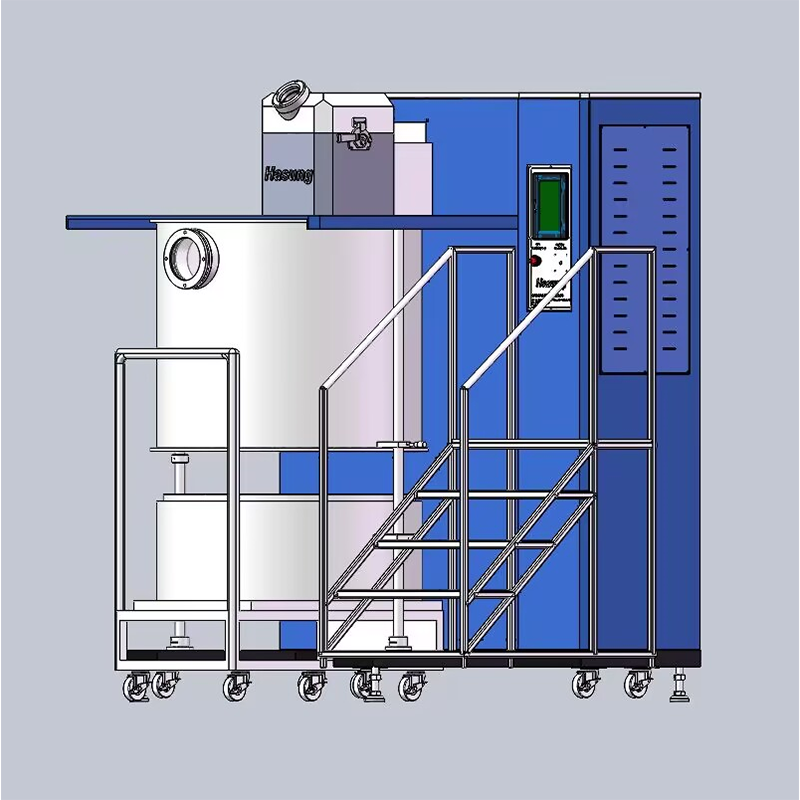

Metal Powder Mvura Atomizer YeInokosha Metal Platinum Palladium Steel

Zvigadzirwa Zvinotsanangurwa

Induction kupisa pasi pekuchengetedzwa kwegasi inert, uchishandisa graphite crucible, kunyunguduka tembiricha kusvika 1600 madhigirii. HT yakakwira tembiricha mhando inogona kushandiswa, uchishandisa ceramic crucible (graphite susceptor), tembiricha yekunyunguduka inogona kusvika 2000 madhigirii. Iyo inopisa gasi yekugovera system inogona kuwedzerwa, uko gasi rinopisa kusvika ku500 madhigirii ekugadzira mapfudze esimbi akanakisa. Midziyo yacho inogadzira spherical simbi poda ine fluidity yakanaka uye particle size pakati pe10 ne200 microns, kutowedzera kusvika #400, 500 #. Inogona kushandiswa mukugadzira maitiro senge laser selective sintering uye poda metallurgy.Zvakanakira zveHasung AU zvakatevedzana zvishandiso:

- Compact chimiro uye nyore kushanda

-Kuchinjika uye kunoshanda kugadzirwa kwezvimedu zvidiki zvesimbi poda

- Nyore uye inokurumidza alloy shanduko uye nozzle kutsiva

-Yakakwira hupfu hwekubvisa mwero uye kugaya kurasikirwa mwero wakaderera se1/1000

- Yakagadzikana yekugadzira maitiroZvinokosha Zvimiro zveHasung AU Series Zvishandiso:

- Graphite crucible inogona kupisa kusvika ku2000 madhigirii munzvimbo yekudzivirira gasi

- Microprocessor inodzorwa induction mota (400 volts, 3 chikamu simba)

- Yakanakisa mvura simbi yekusanganisa basa, iyo inogona kusanganisa uye kunyungudutsa simbi dzakasiyana pamberi pegasi atomization

- Munzvimbo yekudzivirira gasi, iyo yekudyisa system inogona kuwedzerwa kuti ichinje alloy kuumbwa

- Yakanyatso kudzora tembiricha uchishandisa N-mhando uye S-mhando thermocouples

- Crucible simba 1500cm3, 3000cm3 uye 12000cm3 sarudzo

- Shandisa argon kana nitrogen anosvika makumi matatu emumhepo

- Iyo gasi yekudziya system inogona kuwedzerwa kupisa gasi kusvika ku500 madhigirii ekugadzirwa kwehupfu nediki diki.

-Kukurumidza uye nyore kuchinja pakati pemamodhi maviri ekugaya kuitira kugadzirwa kwakanaka kwehupfu hwemhando dzakasiyana siyana

- Yakakwenenzverwa mhepo yekuyerera kwemhepo kudzivirira setiraiti zvimedu zvekuyerera kwakanaka kwehupfu

-Kuunganidzwa kwesimbi yakaoma poda mushongwe yeguruva pasi pegasi rekudzivirira

-Kuunganidzwa kwefaindi uchishandisa pneumatic sefa

- Inogona kuchengeta anopfuura zana parameter marongero

-Chishandiso chinogona kushandirwa kure neiyo GSM unit -

100 mesh - 400 mesh Metal Powder Mvura Atomizer Machine

Iyo inonyanya kukodzera kugadzira hupfu (kana granular) zvinhu mutangi yeatomizing mushure mekunyungudusa simbi kana simbi alloys (yakajairika kunyungudika kana vacuum kunyungudika kunogona kushandiswa). Inonyanya kushandiswa mumayunivhesiti, masangano ekutsvakurudza kwesayenzi, etc. Metal atomization poda inogona kugadzirwa nepamusoro pekumanikidzwa kwemvura atomization maererano nehupfu.

Iyi midziyo yakakodzerawo kugadzirwa uye tsvakiridzo yekuwedzera kugadzira (goridhe refining) simbi poda kugadzirira mumayunivhesiti uye nesainzi tsvakurudzo masangano.

Midziyo yacho yakakodzerawo kutsvagisa nekugadzirwa kwemhando dzakasiyana dzesimbi isina tsvina, alloy simbi, mhangura hupfu, aruminiyamu poda, sirivheri poda, ceramic hupfu uye brazing poda.