Metal Powder Mvura Atomizer YeInokosha Metal Powder Goridhe Silver Copper

Features

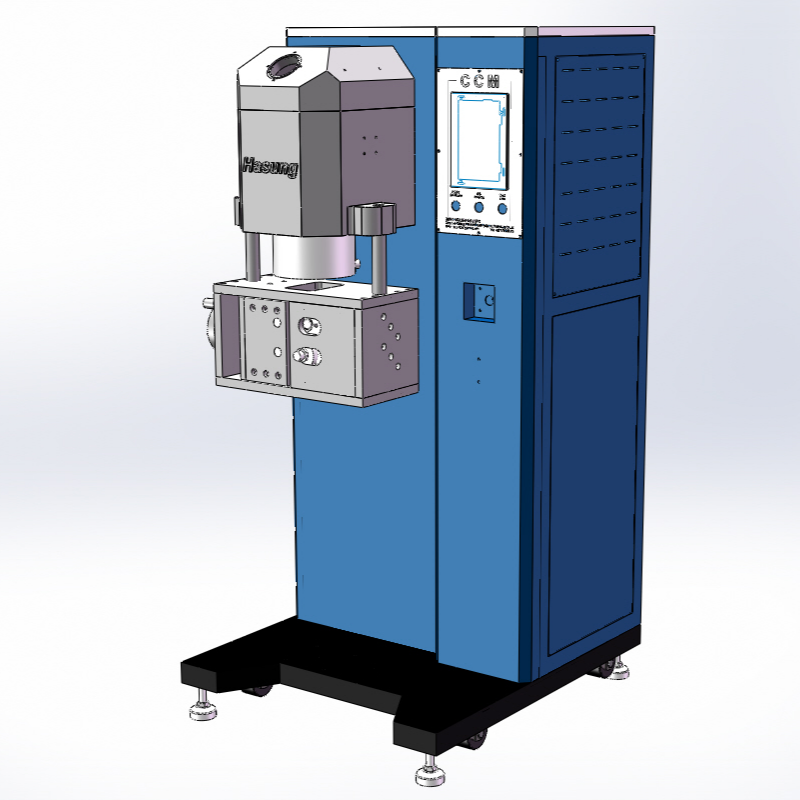

HS-MI1 imhuri yemaatomizer emvura akagadzirirwa kugadzira simbi yehupfu yechimiro chisina kujairika, kuti ishandiswe muindasitiri, makemikari, solder paste, resin mafirita, MIM uye sintering application.

Iyo atomizer inobva pane induction furnace, ichishanda mukamuri yakavharwa pasi pemhepo yekudzivirira, apo simbi yakanyungudutswa inodururwa uye inorohwa nejeti yemvura yakanyanyisa, ichibudisa poda yakanaka uye deoxidized.

Induction heat inovimbisa yakanaka kwazvo homogenization yekunyunguduka nekuda kwekuita kwemagineti kukurudzira panguva yechikamu chakanyungudutswa.

Iyo die unit yakashongedzerwa neyekuwedzera induction jenareta, iyo inobvumira kutangazve kutenderera kana paine kukanganisa kutenderera.

Kutevera nhanho dzekunyunguduka uye homogenization, simbi inodirwa yakatwasuka kuburikidza nejekiseni system yakamisikidzwa pachigadziko chepasi checrucible (nozzle).

Mazhinji nzizi dzemvura dzakasimba dzakanangidzirwa uye dzakanangidzirwa padanda resimbi kuitira kuti ive nechokwadi chekukurumidza alloy kusimba muchimiro chehupfu hwakatsetseka.

Real-time process inosiyana senge tembiricha, gasi kumanikidza, induction simba, okisijeni ppm zvirimo mukamuri uye nezvimwe zvakawanda, zvinoratidzwa mune ese manhamba uye graphical fomati pane yekutarisa sisitimu yekunzwisisa intuitive kutenderera kwekushanda.

Iyo sisitimu inogona kushandirwa nemaoko kana mune yakazara otomatiki modhi, nekuda kwekurongeka kweseti yese yemaitiro paramita kuburikidza nemushandisi-ushamwari touch-screen interface.

Maitiro Ekugadzira Metal Powder NeMvura Atomization Pulverizing Equipment

Maitiro ekugadzira simbi hupfu nemvura atomization pulverizing midziyo ine nhoroondo refu.Munguva dzekare, vanhu vaidira simbi yakanyungudutswa mumvura kuti iputse musimbi yakanaka kwazvo, iyo yaishandiswa sezvinhu zvokugadzira simbi;kusvika zvino, kuchine vanhu vanodira mutobvu wakanyungudutswa zvakananga mumvura kuti vagadzire mapeteti emutobvu..Uchishandisa nzira yeatomization yemvura kugadzira coarse alloy poda, iyo process musimboti yakafanana neyataurwa pamusoro pemvura inoputika simbi yemvura, asi iyo pulverization inoshanda yakagadziridzwa zvakanyanya.

Iyo mvura atomization pulverizing midziyo inogadzira coarse alloy poda.Kutanga, goridhe rakagosha rinonyungudutswa muchoto.Iyo yakanyungudutswa yegoridhe mvura inofanirwa kupiswa neanenge 50 madhigirii, uye yozodururwa mu tundish.Tanga iyo yepamusoro-inodzvinyirira mvura pombi isati yaiswa goridhe mvura, uye rega iyo yepamusoro-inomanikidza mvura atomization mudziyo utange iyo workpiece.Mvura yegoridhe iri mu tundish inopfuura nepadanda yopinda muatomizer nemumuromo unobvinza uri pazasi pe tundish.Atomizer ndiyo yakakosha midziyo yekugadzira coarse goridhe alloy poda nepamusoro-inomanikidza mvura mhute.Hunhu hweatomizer hunoenderana nekupwanya kwehupfu hwesimbi.Pasi pekuita kwemvura yakakwira-kudzvanya kubva kuatomizer, iyo yegoridhe mvura inoramba ichiputswa kuita madonhwe akatsetseka, ayo anowira mumvura inotonhorera mumudziyo, uye mvura inokurumidza kuoma kuita alloy poda.Muchinyakare nzira yekugadzira simbi poda nepamusoro-kudzvinyirira mvura atomization, iyo simbi poda inogona kuunganidzwa nguva dzose, asi pane mamiriro ezvinhu ekuti hushoma hwesimbi hupfu hunorasika nemvura yeatomizing.Mukuita kugadzira alloy poda nepamusoro-kudzvanywa kwemvura atomization, chigadzirwa cheatomi chakaiswa mumudziyo weatomization, mushure mekunaya, kusefa, (kana zvichidikanwa, inogona kuomeswa, kazhinji inotumirwa zvakananga kune inotevera maitiro.), kuwana yakanaka Alloy poda, hapana kurasikirwa kwealloy poda mukuita kwese.

Seti yakakwana yemvura atomization pulverizing zvishandiso Zvishandiso zvekugadzira alloy poda ine zvikamu zvinotevera:

Chikamu chekunyungudutsa:yepakati-frequency simbi yekunyungudutsa choto kana yakakwira-frequency simbi yekunyungudutsa vira inogona kusarudzwa.Kugona kwechoto kunotarirwa maererano nehuwandu hwekugadzirisa hupfu hwesimbi, uye 50 kg yevira kana 20 kg yevira inogona kusarudzwa.

Atomization chikamu:Midziyo iri muchikamu ichi isiri-yakajairwa midziyo, iyo inofanirwa kugadzirwa uye kurongeka zvinoenderana nesaiti mamiriro emugadziri.Iko kune kunyanya tundishes: apo tundish inogadzirwa munguva yechando, inoda kuve yakatsva;Atomizer: Iyo atomizer ichauya kubva mukudzvanywa kwepamusoro Mvura yepombi inodzvanyirira mvura yegoridhe kubva pa tundish nekumhanya kwakafanotemerwa uye kona, ichiipwanya kuita madonhwe esimbi.Pasi pesimba repombi yemvura yakafanana, huwandu hwehupfu hwesimbi yakatsetseka mushure meatomization hunoenderana nekushanda kweatomizer kweatomizer;iyo atomization cylinder: inzvimbo iyo alloy poda inogadziriswa, yakapwanyika, yakanyoroveswa uye inounganidzwa.Kuti udzivirire ultra-fine alloy powder mune yakawanikwa alloy poda kubva pakurasikirwa nemvura, inofanira kusiiwa kwenguva yakati mushure meatomization, uye yozoiswa mubhokisi rekuunganidza hupfu.

Post-processing chikamu:bhokisi rekuunganidza poda: rinoshandiswa kuunganidza iyo atomize alloy poda uye kuparadzanisa uye kubvisa yakawandisa mvura;kuomesa choto: omesa upfu hwakanyorova nemvura;muchina wekuongorora: sieve iyo alloy poda, Kunze-kwe-kutsanangurwa coarser alloy poda inogona kunyungudutswa zvakare uye neatomu sechinhu chekudzoka.

Iyo Yekuvandudza Maitiro eAtomization Pulverizing Equipment Mune Ramangwana

Pachine zvakawanda zvinoshomeka mukunzwisisa kwe 3D tekinoroji yekudhinda mune ese maficha eChina ekugadzira indasitiri.Tichitarisa kubva pamamiriro chaiwo ebudiriro, kusvika pari zvino kudhinda kwe3D hakusati kwawana maindasitiri akura, kubva kumichina kuenda kune zvigadzirwa kusvika kune masevhisi achiri muchikamu che "advanced toy".Nekudaro, kubva kuhurumende kuenda kumabhizinesi muChina, tarisiro yebudiriro ye 3D yekudhinda tekinoroji inowanzo zivikanwa, uye hurumende nenzanga kazhinji vanoteerera kukanganiswa kweramangwana 3D kudhinda simbi atomization pulverizing midziyo tekinoroji pakugadzirwa kwenyika yangu iripo, hupfumi, uye mienzaniso yekugadzira.

Zvinoenderana nedata reongororo, parizvino, kudiwa kwenyika yangu kweiyo 3D tekinoroji yekudhinda haina kutariswa pamidziyo, asi inoratidzwa mumhando dzakasiyana dze3D kudhinda zvigadzirwa uye kudiwa kwemaagency kugadzirisa masevhisi.Vatengi vemaindasitiri ndivo vane simba guru pakutenga michina yekudhinda ye3D munyika yangu.Midziyo yavanotenga inonyanya kushandiswa mundege, ndege, zvigadzirwa zvemagetsi, zvekufambisa, dhizaini, hunyanzvi hwetsika uye mamwe maindasitiri.Parizvino, huwandu hwakaiswa hwemaprinta e3D mumabhizinesi eChinese angangoita mazana mashanu, uye mwero wekukura wepagore ungangoita 60%.Kunyange zvakadaro, saizi yemusika iripo inongosvika zana remamiriyoni eyuan pagore.Kugona kudiwa kweR&D nekugadzirwa kwezvinhu zvekudhinda zve3D kwasvika panosvika bhiriyoni imwe yeyuan pagore.Nekuzivikanwa uye kufambira mberi kwehunyanzvi hwemichina, chiyero chinokura nekukurumidza.Panguva imwecheteyo, 3D kudhinda-ane chekuita neakachengeteswa masevhisi ekugadzirisa ane mukurumbira zvikuru, uye akawanda maajenti 3D kudhinda Kambani yemidziyo yakakura kwazvo mukuita laser sintering uye kushandiswa kwemidziyo, uye inogona kupa ekunze masevhisi ekugadzirisa.Sezvo mutengo wemudziyo mumwe uchiwanzopfuura 5 miriyoni yuan, kugamuchirwa kwemusika hakuna kukwira, asi iyo agency yekugadzirisa sevhisi yakakurumbira.

Zvizhinji zvezvinhu zvinoshandiswa munyika yangu 3D yekudhinda simbi yeatomization pulverizing michina inopihwa zvakananga nevanomhanyisa prototyping vagadziri, uye wechitatu-bato rekupa zvinhu zvakajairika haasati aitwa, zvichikonzera kudhura kwakanyanya kwezvinhu.Panguva imwecheteyo, hapana tsvakiridzo yekugadzirira hupfu yakatsaurirwa kudhinda kwe3D kuChina, uye pane zvakaomesesa zvinodikanwa pakugovera saizi yechikamu uye neokisijeni yemukati.Mamwe mayunitsi anoshandisa yakajairwa pfapfaidzo poda panzvimbo, iyo ine yakawanda isingashande.

Kuvandudzwa uye kugadzirwa kwezvinhu zvakasiyana-siyana ndiyo kiyi yekufambira mberi kwetekinoroji.Kugadzirisa mashandiro uye matambudziko emitengo yezvinhu kuchasimudzira zvirinani kusimudzira kwekukurumidza prototyping tekinoroji muChina.Parizvino, zvizhinji zvezvinhu zvinoshandiswa munyika yangu 3D kudhinda nekukurumidza prototyping tekinoroji inoda kutengwa kubva kunze kwenyika, kana vagadziri vemidziyo vakaisa simba rakawanda nemari yekuzvigadzira, izvo zvinodhura, zvichikonzera kuwedzera kwemitengo yekugadzira, ukuwo. zvinhu zvemumba zvinoshandiswa muchina uyu zvine simba rakaderera uye nemazvo..Iko kugadzirwa kwe3D zvinyorwa zvekudhinda kwakakosha.

Titanium uye titanium alloy poda kana nickel-based uye cobalt-based superalloy poda ine yakaderera oxygen content, yakanaka particle size uye high sphericity inodiwa.Iyo poda particle size inonyanya -500 mesh, iyo okisijeni yemukati inofanira kunge yakaderera pane 0.1%, uye particle size inofanana Parizvino, yakakwirira-yekupedzisira alloy poda uye zvigadzirwa zvekugadzira zvichiri kunyanya kuvimba nekunze.Munyika dzekunze, zvigadzirwa nemidziyo zvinowanzounganidzwa uye kutengeswa kuti vawane purofiti yakawanda.Tichitora nickel-based powder semuenzaniso, mutengo wezvinhu zvakabikwa ungangoita 200 yuan/kg, mutengo wezvigadzirwa zvemumba unowanzoita 300-400 yuan/kg, uye mutengo wehupfu hunotengwa kunze kwenyika kazhinji unodarika 800 yuan/kg.

Semuyenzaniso, pesvedzero uye kuchinjika kwekuumbwa kwehupfu, inclusions uye zvimiro zvemuviri pane yakabatana tekinoroji ye3D yekudhinda simbi atomization poda milling michina.Naizvozvo, tichitarisa mashandisirwo ekushandiswa kweyakaderera okisijeni yemukati uye yakanaka particle size poda, zvichiri kudikanwa kuita basa rekutsvagisa senge dhizaini yekugadzira titanium uye titanium alloy poda, gasi atomization poda yekugaya tekinoroji yefine particle size poda, uye pesvedzero yehupfu hunhu pakuita kwechigadzirwa.Nekuda kwekuganhurirwa kwehunyanzvi hwekugaya muChina, zvakaoma kugadzirira poda yakatsetseka pari zvino, goho rehupfu rakaderera, uye zvirimo zveokisijeni nezvimwe zvisina kuchena zvakakwirira.Munguva yekushandiswa kwekushandisa, hupfu hunonyunguduka hunowanzoita kusaenzana, zvichiita kuti pave nepamusoro-soro ye oxide inclusions uye denser zvigadzirwa muchigadzirwa.Matambudziko makuru emumba alloy poda ari mumhando yechigadzirwa uye batch kugadzikana, zvinosanganisira: ① kugadzikana kwezvikamu zvehupfu (nhamba yekubatanidzwa, kufanana kwezvikamu);② hupfu hwemuviri Kugadzikana kwekuita (particle size distribution, powder morphology, fluidity, loose ratio, etc.);③ dambudziko regoho (yakaderera goho rehupfu mune yakamanikana particle size chikamu), nezvimwe.

Technical Parameter

| Muenzaniso Nha. | HS-MI4 | HS-MI10 | HS-MI30 |

| Voltage | 380V 3 Zvikamu, 50/60Hz | ||

| Magetsi | 8KW | 15KW | 30KW |

| Max Temp. | 1600°C/2200°C | ||

| Nguva yekunyunguduka | 3-5 Min. | 5-8 Min. | 5-8 Min. |

| Kukandira Zviyo | 80#-200#-400#-500# | ||

| Temp Accuracy | ±1°C | ||

| Capacity | 4kg (Goridhe) | 10kg (Goridhe) | 30kg (Goridhe) |

| Vacuum Pombi | German vacuum pombi, vacuum dhigirii - 100Kpa (kusarudza) | ||

| Application | Ndarama, sirivha, mhangura, alloys;Platinum(Inosarudzika) | ||

| Operation nzira | Imwe-kiyi oparesheni yekupedzisa hurongwa hwese, POKA YOKE foolproof system | ||

| Kudzora System | Mitsubishi PLC+Munhu-muchina interface intelligent control system (optional) | ||

| Shielding Gasi | Nitrogen/Argon | ||

| Kutonhora mhando | Chiller yemvura (inotengeswa zvakasiyana) | ||

| Dimensions | 1180x1070x1925mm | 1180x1070x1925mm | 3575*3500*4160mm |

| Kurema | approx.160kg | approx.160kg | approx.2150kg |

| Machine type | Paunenge uchigadzira grits yakanaka senge 200 #, 300 #, 400 #, muchina unenge uri masitepisi hombe mhando.Paunenge uchigadzira pazasi grit #100, saizi yemuchina idiki. | ||

Product Display

-11.jpg)