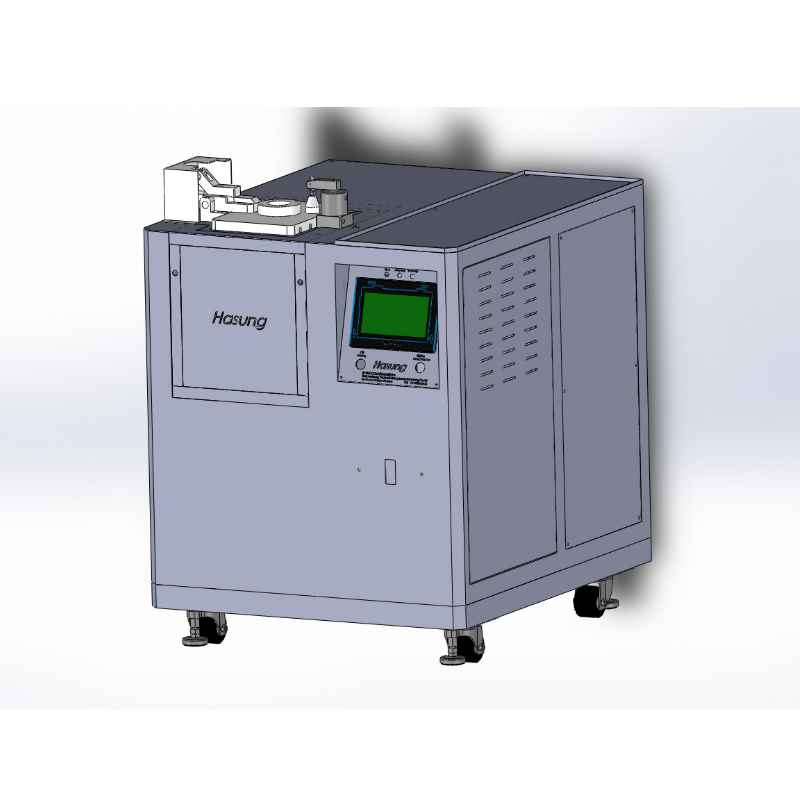

TVC Series Induction Vacuum Pressure Kukanda Machine yeGoridhe Silver Copper

Sei Iwe Uchisarudza Hasung Vacuum Pressure Casting Machine?

Features

Hasung otomatiki vacuum Kukanda michina enzanisa nemamwe makambani

TVC yakatevedzana yekukanda muchina ndiyo yakanyanya hunyanzvi muchizvarwa chazvino chekumanikidza vacuum yekukanda muchina mumusika wepasi rose.Ivo vanoshandisa yakaderera-frequency jenareta, uye simba rekutonga rakaenzana uye rinotungamirirwa zvachose nekombuta.Mushandi anongoisa simbi mucrucible, oisa silinda uye odzvanya bhatani!Iyo "TVC" yakatevedzana modhi inouya ne 7-inch color touch screen.Munguva yese yekubatanidza, kuvhiya kunoitwa zvishoma nezvishoma.

Automatic process:

Kana wadzvanya bhatani re "Auto", vacuum, inert gasi, kudziyisa, yakasimba magineti kusanganisa, vacuum, kukanda, , vacuum nekumanikidza, kutonhora, ese maitiro anoitwa neimwe kiyi modhi.

Pasinei nemhando uye huwandu hwegoridhe, sirivheri, uye alloy, iyo frequency uye simba zvinogadziriswa.Kana simbi yakanyungudutswa yasvika patembiricha yekukanda, komputa inogadzirisa kudziyisa uye inoburitsa mapuruzi epasi-pasi kuti inzwe alloy inomutsa.Kana zvese zvakaiswa paramita zvasvika uye tembiricha inodzikama pakutsauka kwakanyanya pa ± 4 ° C, kukanda kunotanga otomatiki, kuchiteverwa nekumanikidza kwakasimba kwesimbi ine gasi inert.

TVC yakatevedzana yekukanda muchina ndeimwe yeakanyanya hunyanzvi muchizvarwa chazvino chekumanikidza vacuum yekukanda muchina mumusika wepasi rose.

Ivo vanoshandisa yakaderera-frequency jenareta, uye simba rekutonga rakaenzana uye rinotungamirirwa zvachose nekombuta.

Mushandi anongoisa simbi mucrucible, oisa silinda uye odzvanya bhatani!The

"TVC" series modhi inouya ne 7-inch color touch screen.

Munguva yese yekubatanidza, kuvhiya kunoitwa zvishoma nezvishoma.

Pasinei nemhando uye huwandu hwegoridhe, sirivheri, uye alloy, iyo frequency uye simba zvinogadziriswa.

Kana simbi yakanyungudutswa yasvika patembiricha yekukanda, komputa inogadzirisa kudziyisa uye inoburitsa mapuruzi epasi-pasi kuti inzwe alloy inomutsa.

Kana zvese zvakaiswa paramita zvasvika uye tembiricha inodzikama pakutsauka kwakanyanya pa ± 4 ° C, kukanda kunotanga otomatiki, kuchiteverwa nekumanikidza kwakasimba kwesimbi ine gasi inert.

Technical Parameters

| Muenzaniso Nha. | HS-TVC1 | HS-TVC2 | HS-TVC4 | HS-TVC6 | HS-TVC8 |

| Voltage | 220V chikamu chimwe chete / 380V 3 zvikamu 50/60Hz | 380V 3 zvikamu, 50/60Hz | |||

| Magetsi | 10KW | 15KW | 20KW | ||

| Max Temp | 1500°C | ||||

| Nguva yekunyunguduka | 2-3 min. | 3-5 min. | 3-5min | 3-5 min. | 4-6 min. |

| Shielding Gasi | Argon / Nitrogen | ||||

| Pressure | 0.1-0.3Mpa (Inochinjika) | ||||

| Temp Accuracy | ±1°C | ||||

| Kugona (Goridhe) | 1kg | 2kg | 4kg | 6kg | 8kg (Goridhe) |

| Max.Flask size | 4"x10" / 5"x12" | 5"x12"/6.3"x12" | 6.3"x12" | 8.6"x12" / 10"x13" | |

| Vacuum Pombi | High quality vacuum pombi/ German vacuum pombi, vacuum dhigirii - 100KPA (kusarudza) | ||||

| Application | Ndarama, K goridhe, sirivheri, mhangura uye mamwe alloys | ||||

| Operation nzira | Imwe-kiyi oparesheni yekupedzisa hurongwa hwese, POKA YOKE foolproof system | ||||

| Kutonhora mhando | Mvura inotonhorera (inotengeswa zvakasiyana) kana Mvura inomhanya | ||||

| Dimensions | 680*880*1230mm | ||||

| Kurema | approx.150kg | approx.150kg | approx.160kg | approx.180kg | approx.250kg |

Product Display

Nzira dzekukanda

Iyo yakajairika nzira yekukanda ndeiyi:

kupisa moto

induction casting

vacuum pressure die-casting

Flame casting

Kukanda murazvo ndiyo nzira yechinyakare yekukanda uye ingangove ndiyo yakajairika uye isingadhure.Iyi nzira yave ichibatsira kugadzira matekiniki ekukanda asi haienderane nezvinodiwa zvepamutemo uye zvehunyanzvi zvemusika wemazuva ano.Iyi nzira inongobva pahunyanzvi hwemushandisi uye hunyanzvi: kushandiswa kwehunyanzvi uhu kunoda kugona kudzora murazvo, ruzivo rwakanaka rwekugadzira simbi pamwe nekunzwa uye kungwarira kwekushanda.Kunyangwe chiri chokwadi kuti vazhinji vanofambisa inyanzvi dzechokwadi dzehunyanzvi uhu isu. funga kuti tekinoroji iyi haizovimbisi kuberekana uye nekugara kwemhando yepamusoro.Uye kana maitiro, akadai seaya, akanyatsoenderana nehunyanzvi uye kugona kwemushandisi haisi nzira inochinjika, uye kuchinjika chinhu chakakosha chinodiwa kumarabhoritari emazuva ano emazino.Maitirwo acho anofanira, zvechokwadi, kudhindwa zvisinei nehunyanzvi hwevashandisi.Pamusoro peizvi nzira yekukanda murazvo haitenderi chitupa uye kunyora kwemaitiro ekukanda nenzira yeatomatiki maitiro ekudzora masisitimu.

Induction casting

Induction casting zvirokwazvo yakamiririra kubudirira muchikamu chekukanda asi zvisinei neizvi tekinoroji ine zvimwe zvinhu zvinoita kuti isakwanise kuishandisa nenzira ine musoro uye yakarongeka murabhoritari yenyanzvi yemazino.Iyo induction system ndeye semi-otomatiki muzvisikwa uye yese. maitiro, sekukanda murazvo, zvinoenderana nehunyanzvi hwemushandisi.Ichokwadi kuti mushandisi ane basa rekuongorora kana kunyungudika kwanga kuri kwechokwadi uye kumutsa mudziyo wepakati.«Saka, kuberekana uye kugara kwemhando yepamusoro hakugone kuvimbiswa uchishandisa nzira iyi.Induction casting inokurumidza.Iyo alloy yesimbi inopisa kubva mukati kusvika kunze.Unyanzvi hwekugadzirwa kweiyo induction system inoita kuti zvisakwanise kudzikamisa tembiricha yealloy nekufamba kwenguva kana kuvharira kuwedzera tembiricha.The centrifugal pressure is unidirectional uye akawanda induction casting machines haaite vacuum system, saka mhepo inowanikwa muyuniti inogona kukonzera. a porous casting.

Vacuum pressure die-casting

Iyo vacuum pressure die casting yagara ichionekwa seyemhando yepamusoro yekukanda maitiro, zvisinei mukurumbira wayo wakaramba wakaganhurirwa kusvika pakati pe-90s nekuda kwekuti tembiricha yakasvikwa nemidziyo iyi yaive isina kukodzera kunyungudutswa nekukandwa kwemazino matsva alloys.Chizvarwa chitsva chemidziyo chakazogadzirwa, chaigona kunyungudutsa base-simbi, semi-yakakosha, Palladian uye akakosha mazino alloys.

Iyo Hasung vacuum pressure die-casting machines inoratidzira yakanakisa kunyunguduka tembiricha yekudzora, ichigadzira iyo yekukanda muvacuum uye ichiita kuti zvikwanise kuita akawanda-directional kumanikidza.Zvese izvi zvinogonesa kuchinjika kukuru kwekushandisa, kuberekana uye kugara kwemhando uye kunoderedza kukanganiswa kwemushandisi pamhedzisiro.

Nzira yekuwana sei kukanda kwakanaka

Tevera kukanda tembiricha zvinodiwa

Kuchengeta kutonga pamusoro pekukanda tembiricha ndicho chinonyanya kukosha chinodiwa kuchengetedza metallurgic maficha eiyo alloy.Kutevedzera data rekukanda uye ma specifi cations kwakakosha kuti udzivise kunyungudika kwepasi kunyungudika masimbi ari mualloy.

Simbi yakanyungudutswa pane tembiricha yakakodzera ichave iine ese maficha akatemerwa nekambani yekugadzira, zvikasadaro panogona kuve nekumwe shanduko mune metallurgic chimiro chesimbi iyo inogona kukonzera shanduko muhunyanzvi hupfumi uye matambudziko panguva dzinotevera dzekugadzirisa zvikamu.

Kukanda neomnidirectional pressure

Dental alloys anoumbwa nesimbi akati wandei, imwe neimwe iine chaiyo c density.Nekushandisa centrifugal jekiseni maitiro mhedzisiro ichava mono-directional kumanikidza umo simbi dzine yakakwirira specifi c densities inounzwa muhumburumbira pamberi peiyo ine yakaderera densities.Uchishandisa nzira dzekudzvanya dzekukandira, simbi inounzwa statically muhumburumbira uye ipapo silinda inoratidzwa kune omni-directional uye inogara ichimanikidza inobvumira kukwana kwesimbi.

Vacuum casting

Kuti uwane yakakwira mechanical kuramba uye kurongeka kukanda kuchaitwa munzvimbo isina airfree.Izvi zvinovimbisa zvachose isina porous alloy casting.

Zvakanakira zveHasung die-casting system

Kutevedzera tembiricha yakatarwa cations

Izvi zvinogoneka nekuda kweiyo system inosanganisa kutonga ne microprocessor, thermocouple uye control logic, inoitwa neyakaomesesa yemagetsi system ine infra-red pointer.

Zvakanakira: Kunyanya kurongeka mukugadzirwa kwealloy nekuzotevera kuchengetedza kwemetallurgic specifi cations.

Omnidirectional pressure pasimbi

Otomatiki compression inoburitsa yunifomu uye kunyangwe kudzvanywa pahumburumbira yese.Iko hakuna centrifugal mhedzisiro yesimbi inoumba alloy.

Zvakanakira: Yepamusoro alloy compactness, zvirinani layering, kuchengetedza alloy zvinhu (hapana chikonzero chekuwedzera zvinhu kuti zvishandiswe kumachaneli uye yakawandisa yakakandwa zvinhu)

Kunyunguduka kunoitwa munzvimbo yemhepo

Asi kukanda kunoitwa munzvimbo isina mweya nekuti TVC yakatevedzana yekukanda michina, isati yapunduka, inoita mhepo yemahara yekugadzira otomatiki maitiro.

Zvakanakira: Kunyanya kurongeka, mhando yepamusoro uye kuchengetedza nguva mukupedzisa mabasa.

Maximum oparesheni inoshanduka

Kushandiswa nezvikamu zvese zverabhoritari nekuti hapana kupindira kwevanhu.

Zvakanakira: Kushandiswa nezvikamu zvese zverabhoritari.

Quality reproducibility

Iyo nzira ndeye otomatiki uye haina kupindira kwevanhu.

Zvakanakira: Iyo otomatiki kutenderera uye kusavapo kwekupindira kwevanhu kunopa kuberekana kwakakwana kwemhedzisiro.

Kutungamira kunoshanda

Yakazara maitiro manejimendi ndeye 100% inodhura inoshanda: magetsi emagetsi mashandisirwo akadzikira uye zvinodyiwa hazvidhure.

Zvakanakira: mari inobudirira.

Vacuum pressure casting machine zvinodyiwa:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic jacket

4. Graphite chivharo

5. Thermocouple

6. Kupisa coil

Iyo yakazara jewellery yekugadzira mutsara inosanganisira:

1. 3D printer

2. Vulcanizer

3. Wakisi jekiseni

4. Ovheni yakatsva

5. Vacuum pressure casting machine

6. Kuchenesa

7. Kukwenenzvera

Mazuva ano, mafekitori ezvishongo anoda kuve neakazara otomatiki ekukanda masisitimu ayo anochengetedza yakawanda yemitengo yevashandi uye inowedzera kushanda zvakanaka kwekugadzira.PaHasung, tinokupa iwe zvizere zvishongo zvekukanda mhinduro pamhando yepamusoro zvigadzirwa zvakavimbiswa kubva kuChina.

.png)