Products

-

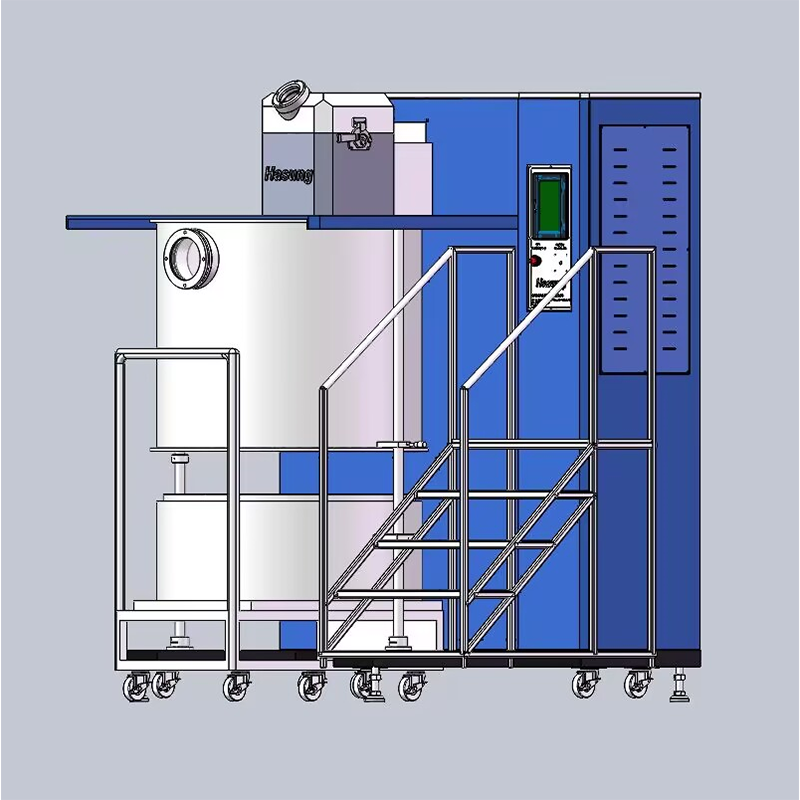

Unoramba Uchikanda Muchina weGoridhe Silver Copper Alloy 20kg 30kg 50kg 100kg

1.Pakarepo sirivha yegoridhe strip waya chubhu tsvimboinoenderera mberi ichikanda muchinanokuti zvishongo zvakatangwa pamusika, yakagamuchira mhinduro yakanaka kubva kune vatengi vakawanda, avo vakati rudzi urwu rwechigadzirwa runogona kugadzirisa zvinobudirira zvavanoda.Uyezve, chigadzirwa chacho chinoshandiswa zvakanyanya muMetal Casting.

2.Inoenderera mberi Casting Machine yeKugadzira Rod Strip Pipe ine 20kg 30kg 50kg 100kg kana ichienzaniswa neyakafanana zvigadzirwa pamusika, ine zvisingaenzaniswi zvakatanhamara zvakanakira maererano nekuita, mhando, chitarisiko, nezvimwewo, uye inonakidzwa nemukurumbira wakanaka mumusika.Hasung inopfupikisa kukanganisa kwezvigadzirwa zvekare, uye inoramba ichivandudza. Izvo zvinotsanangurwa zveUnoramba Uchikanda Muchina weKugadzira Rod Strip Pipe ine 20kg 30kg 50kg 100kg inogona kugadzirwa zvinoenderana nezvaunoda.

-

Metal Flakes Processing Machine Gold Flakes Kugadzira Equipment yeGoridhe Kunatsa

Equipment sumo:

1. Adopt medium frequency induction, nguva pfupi yekunyunguduka uye kushanda kwakanyanya.

2. Imba yakanyunguduka inoshandisa inert gasi iyo inoshandiswa kudzivirira oxidation yezvinhu zvesimbi uye kuiswa kwetsvina. Nechinangwa ichi, yakakodzera kune yakakwirira-kuchena simbi zvinhu kana kunyungudutswa ine nyore oxidized zvinhu.

3. Iyo mechanical inokurudzira basa pasi pevacuum state inogamuchirwa, uye kuumbwa kwemavara hakuna kuparadzaniswa.

4. Kunyunguduka kunodzivirirwa ne-high-purity inert gas, saka graphite ruthenium ine zvishoma zvishoma oxidation kurasikirwa.

5. Kushandisa Taiwan Weinview/Siemens PLC controller, kushanda kuri nyore.

6. Iyo mold inodziya yega panguva yekudurura kuti ive nechokwadi chekukanda.

7. Nezvizhinji zvepasi rose zvine mukurumbira mhando zvikamu zvekuve nechokwadi chemhando yepamusoro.8. Kazhinji inoshandiswa pakunatsa goridhe.

-

Rotary Vacuum Induction Melting Furnace (VIM) FIM/FPt (Platinum, Palladium Rhodium uye Alloys)

FIM/FPt ivira rekunyungudusa platinum, palladium, rhodium, simbi, uye tembiricha alloys ane tembiricha michina.

Inogona kushandiswa kuwana kunyungudika kwakakwana kweplatinamu uye palladium alloys pasina chero gasi inclusions.

Inogona kunyunguduka kubva pa500g kusvika pa10kg yePlatinum mumaminitsi.

Iyo yekunyunguduka inoumbwa nemvura-yakatonhodzwa simbi isina simbi casing umo kesi ine crucible rotate uye ingot mold yekukanda kukanda.

Iyo yekunyungudika, homogenization uye chikamu chekukanda chinogona kuitika pasi pevacuum kana mumhepo inodzivirira.

Choto chakazara ne:

- Kaviri nhanho rotary vane vacuum pombi muoiri yekugezera;

- High precision digital pressure sensor;

- Optical pyrometer yekudzora tembiricha;

- Yakakwira chaiyo yedhijitari vacuum switch yevacuum kuverenga + Ratidza.

Zvakanakira

- Vacuum melting tekinoroji

- Manual / otomatiki tilting system

- High kunyungudika tembiricha

Sravana Sameeralu Serial 4th Hasung TechnologyYakakwira Tembiricha Vacuum Induction Inonyungudutsa Furasi Yekuedza Vacuum Inonyungudutsa Furnace

Product Features

1. Kukurumidza kunyunguduka, tembiricha inogona kusvika pamusoro pe2200 ℃

2. Ne mechanical inokurudzira basa, zvinhu zvinokurudzirwa zvakanyanya

3. Yakashongedzerwa neyakarongwa tembiricha yekudzora, isa yekudziya kana kutonhora curve zvinoenderana nezvinodiwa nemaitiro ako, midziyo inozodziya kana kutonhora zvinoenderana neichi maitiro.

4. Nemudziyo wekudira, sampuli yakanyungudutswa inogona kudururwa muingot mold yakagadzirwa, uye chimiro chemuenzaniso waunoda unogona kudururwa.

5. Inogona kunyungudutswa pasi pemamiriro akasiyana-siyana emamiriro ekunze: kunyunguduka mumhepo, mhepo inodzivirira uye yakakwirira vacuum mamiriro, kutenga imwe mhando yemidziyo, kuziva mabasa akasiyana-siyana; chengetedza mari yako kusvika pamwero wakati.

6. Neyechipiri yekudyisa sisitimu: Inogona kuona kuwedzera zvimwe zvinhu panguva yekunyunguduka, izvo zvakakunakira iwe kugadzirira akasiyana masampuli.

7. Muviri wechoto yese isimbi isina tsvina ine kutonhora kwemvura kuve nechokwadi chekuti tembiricha yegoko yakadzikira kupfuura 35 °C kuchengetedza kuchengeteka kwako pachako.

-

Tilting Induction Melting Machine For Gold Silver Copper 2kg 3kg 4kg 5kg 6kg

Magadzirirwo eiyi tilting melting system anobva pane izvo chaizvo zvinodikanwa zveprojekiti uye maitiro, uchishandisa yemazuva ano yepamusoro-tech tekinoroji. Kuchengetedzeka kunovimbiswa.

1. Adopt Germany IGBT yekupisa tekinoroji, otomatiki frequency tracking uye yakawanda yekudzivirira tekinoroji, iyo inogona kunyungudutsa simbi munguva pfupi, kuchengetedza simba uye kushanda zvakanaka.

2. Kushandisa electromagnetic inomutsa basa, hapana kupatsanurwa muvara.

3. Inotora Mistake Proofing (anti-fool) automatic control system, iyo iri nyore kushandisa.

4. Uchishandisa PID tembiricha control system, tembiricha yakanyatsojeka (± 1 ° C) (inoda).

5. Michina yekunyungudutsa yeHS-TFQ inogadzirwa yakazvimiririra uye inogadzirwa nemhando yepamusoro yezvigadzirwa zvekunyungudutsa nekukanda goridhe, sirivheri, mhangura, nezvimwe.

Iyo HS-TFQ yakatevedzana yakagadzirirwa kunyungudutsa platinum, palladium, Rhodium, goridhe, sirivheri, mhangura uye mamwe alloys.

6. Iyi midziyo inoshandisa akawanda ekunze ane mukurumbira mhando zvikamu.

7. Inoramba ichidziya paunenge uchidira zvinwiwa zvesimbi pane yakakura mamiriro ayo anoita kuti vashandisi vawane hukuru hwekukandira.

-

Smelt Oven Induction Speedy Melting 20kg 30kg 50kg 100kg Manual Tilting Gold Smelting Furnace

Tilting Melting Furnaces yekunyungudutsa masimbi akawanda kuita ingots kana mabhuru.

Michina iyi yakagadzirirwa kunyungudusa zvakawanda, semuenzaniso mufekitori yekudzokorodza goridhe yekunyungudika kukuru kwe50kg kana 100kg pabatch.

Hasung TF yakatevedzana - yakaedzwa uye yakaedzwa mumavambo uye nemapoka anokosha ekunatsa simbi.Mavira edu ekunyungudutsa anonyanya kushandiswa munzvimbo mbiri:

1. yekunyungudutsa masimbi akawanda segoridhe, sirivheri kana indasitiri yekugadzira simbi yakaita sezvimedu zvekukanda, 15KW, 30KW, uye inobuda 60KW inobuda nekudzika-frequency tuning zvinoreva kunyungudika nekukurumidza kunonakirwa nemhedzisiro kubva kuChina - kunyangwe kune mavhoriyamu makuru. - uye yakanakisa kuburikidza-kusanganisa.

2. yekukanda huru, inorema zvikamu mushure mekukanda mune mamwe maindasitiri.

Iyo compact uye inodhura-inoshanda-inoshanda yekurereka mavira kubva kuTF1 kuenda kuTF15 anoshandiswa muindasitiri yezvishongo uye mune akakosha simbi foundries, zviitiko zvitsva zvachose. Ivo vakashongedzerwa nehutsva hwepamusoro induction jenareta inosvika pakunyungudika zvakanyanya nekukurumidza uye inova nechokwadi chekusanganisa uye homogenisation yesimbi yakanyungudutswa. Iyo TF20 kusvika kuTF100 modhi, Zvichienderana nemuenzaniso, huwandu hunobva pahuwandu hwe crucible hwe20kg kusvika 100kg yegoridhe, kunyanya kumakambani anokosha anogadzira simbi.

Iyo TFQ yakatevedzana mavira ekurereka akagadzirirwa ese platinamu negoridhe, ese simbi senge platinamu, palladium, simbi isina tsvina, goridhe, sirivheri, mhangura, alloys nezvimwe, inogona kunyungudutswa mumuchina mumwe nekuchinja macrucibles chete.

Iyi mhando yevira yakanakira kunyunguduka kweplatinamu, nekudaro kana uchidira, muchina unoramba uchidziya kusvika wapedza kudira, wobva wazvivhara wega kana wapedza.

-

Induction Melting Furnace yeGoridhe Platinum Silver Copper Rhodium Palladium

Iyo MU melting unit system yakavakirwa pane izvo chaizvo zvinodikanwa zvekunyunguduka kwezvishongo uye zvakakosha simbi yekunatsa chinangwa.

1. HS-MU melting units inogadzirwa yakazvimiririra uye inogadzirwa nemhando yepamusoro yezvigadzirwa zvehunyanzvi zvekunyungudutsa nekukanda goridhe, sirivheri, mhangura nemamwe maalloys.

2. HS-MUQ mavheni ekunyunguduka akashongedzerwa nejenereta imwe chete yekupisa asi kushandiswa kweviri kwekunyunguduka uye kukanda kweplatinum, palladium, simbi isina tsvina, ndarama, sirivha, mhangura uye mamwe alloys, ayo anogona kushandiswa nekushandura crucibles chete. Zviri nyore uye zviri nyore.

-

1kg 2kg Mini Induction Melting Furnace yeGoridhe Silver Copper

Iyo desktop mini induction yekunyungudutsa choto, huwandu kubva pa1kg-2kg, iyo inotora maminetsi 1-2 kunyungudutsa batch rimwe resimbi. Iyo inouya mune compact dhizaini uye inogona kuve maawa makumi maviri nemana ichishanda ichishanda. Zvakare, iyi simbi yevira ine hushamwari hwakatipoteredza, ichishandisa 6KW simba ne220V chikamu chimwe chete chinochengetedza simba rakawanda kuunza mhedzisiro inodiwa.

Iyo inokurudzirwa zvakanyanya kune diki fekitori yezvishongo kana jewelry workshop, inoshanda uye yakareba hupenyu hwekushandisa. Kunyangwe chiri chishandiso chidiki, chinozadzisa basa rakakura kune vashandisi.

Muchina wekudzora tembiricha unosarudzika pamushini uyu.

-

Otomatiki Goridhe Sirivha Bullion Vacuum Kukanda Machine 2KG

Sei Uchisarudza HasungvacuumGold Bar Casting Machine?

Hasung Vacuum Ingot Casting michina (HS-GV2) yakagadzirirwa kukanda 2kg mhando esirivha uye goridhe mabhuru. Uyu muchina wekukanda unouya nekuchinjika pane mold kugadzirisa ako esirivha negoridhe mabara, ingots uye mabhuru nechero dhizaini yako uye saizi.

Iyo inert gasi kamuri yeiyi yegoridhe bhara yekukanda muchina inova nechokwadi chekuti iwe une yekukandira yekupedzisira ine premium mhando uye chitarisiko chegirazi nekubvisa zvachose marudzi ese eporosity, mafungu emvura kana shrinkage muzvidimbu zvako zvekupedzisira.

Kuenzanisa nenzira yechinyakare. Yako yese yekukanda maitiro ichaitwa pasi pevacuum uye inert gasi. Nekudaro ichipa zvigadzirwa zvako zvekukandira kunaka kwakanaka. Nezviri pamusoro apa vafambisi vako vakavimbiswa zvizere kushandisa michina yedu zviri nyore.

Zvinhu zvekutanga zveHasung zvinobva kune anozivikanwa epamba uye ane mukurumbira pasi rose mhando seJapan AirTec, Taiwan Weinview, uye German Siemens, Schneider, Omron, nezvimwe.

-

Otomatiki Goridhe Bullion Vacuum Kukanda Machine 12KG 15KG 30KG

Sei Uchisarudza HasungVacuumGold Bar Casting Machine?

Hasung Vacuum Bullion Casting Machines inofananidzwa nemamwe makambani

1. Yakasiyana Yakakura. mamwe makambani vacuum anodzorwa nenguva. Havasi vacuum chaiyo. Vanongoipomba nenzira yekufananidzira. Pavanomira kupomba, haisi vacuum, inobuda nyore nyore. Yedu inopomba kune yekumisikidza vacuum level uye inogona kuchengetedza vacuum kwenguva yakareba.

2. Nemamwe manzwi, zvavanazvo inguva yekuisa vacuum.

Semuenzaniso, kuwedzera inert gasi mushure meminiti imwe kana masekonzi makumi matatu kunongoitika. Kana iyo isingasviki pane vacuum, inoshandurwa kuita inert gasi. Zviri Muchokwadi, iyo inert gasi nemhepo zvinopihwa panguva imwe chete. Hachisi chivharo zvachose. Vacuum haigoni kuchengetwa kwemaminitsi mashanu. Hasung inogona kuchengetedza vacuum kweanopfuura maawa makumi maviri.

3. Hatina kufanana. Takadhirowa vacuum. Kana ukamisa pombi yevacuum, inogona kuramba ichichengetedza vacuum. Kweimwe nguva yenguva, isu tichasvika seti Mushure mekuisa kukosha, inogona otomatiki kuchinja kune inotevera nhanho uye kuwedzera inert gasi.

4. Hasung zvikamu zvepakutanga mazita anozivikanwa kubva kuJapan, France neGermany.

-

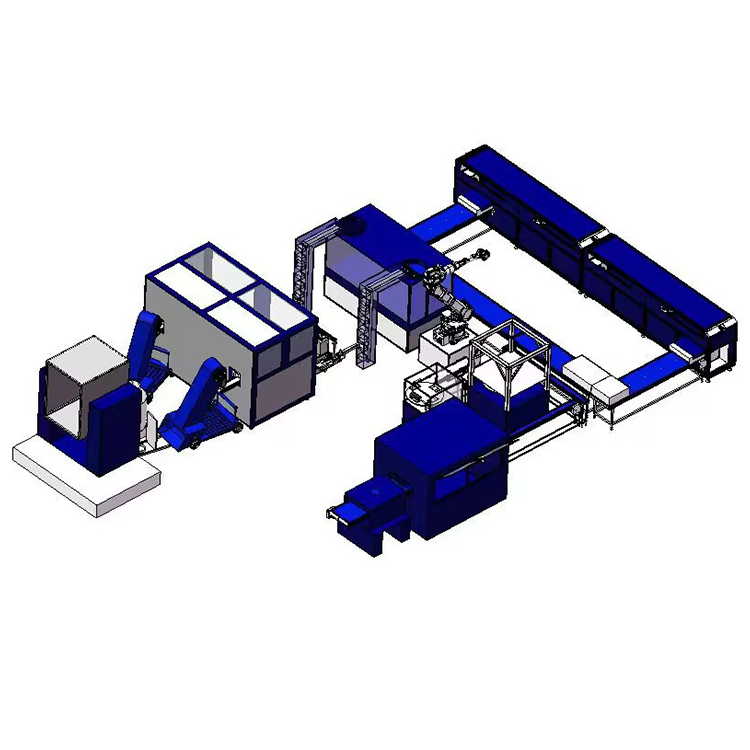

Tunnel Type Goridhe Ingot Vacuum Casting System

HS-VF260 induction tunnel furace iyo, kunyangwe ichisanganisira tekinoroji yepamusoro, inochinjika uye iri nyore kushandisa. Inowanikwa mumhando dzakasiyana, imwe neimwe Tera Automation HS-VF260 yakagadzirwa, inotungamirirwa uye inounganidzwa mukati mekambani yedu.

Choto chedu chemugero chakakamurwa kuita makamuri matatu, umo zviyo zvinonyungudutswa mumhepo inodzorwa uye zvinokandwa mune inopenya uye yakazara yakazara goridhe kana sirivheri ingots. Iyo tekinoroji yakatenderwa inonzi Pinch Valves, yakaiswa kumigumo ese emugero, inovimbisa kuvharwa kwakakwana: sechokwadi, iyi system ine pneumatic mavharuvhu inochengeta okisijeni kunze kwemugero, kuchengetedza inert mhepo uye kuderedza zvakanyanya gasi - kazhinji nitrogen - kushandiswa. . Graphite zvinoshandiswa zvinogara kwenguva refu uye hazvidzike nekuda kweiyo oxidation.

Kufanana nemamwe ese induction yekukandira mavira, choto ichi chinoda kubatanidzwa kune yakaenzana saizi yekumisikidza firiji yemvura.

-

TVC Series Induction Vacuum Pressure Kukanda Machine yeGoridhe Silver Copper

Yakazara otomatiki Vacuum Pressure Kukanda Machine

Tekinoroji nyowani yekusimudzira mhedzisiro yekukanda

Iyo Hasung Casting System

1.Kuvhara chivharo otomatiki, zvese zviri otomatiki kushanda pakukanda kazhinji zvinovandudza kuyerera kwezvinhu uye kuzadza mold.

2.Castings inoratidzira yakakwirira uye inopindirana density

3.Porosity yakanyanya kuderedzwa

4. Kutsungirira Max. 4 mabara ekukanda kumanikidza.

5. SBS yekucheka system pasina kushandisa gaskets, chengetedza mari.

6.Castings vane kunyanya kunetseka uye elasticity zvinhu, zvichiita kuti zvive nyore kugadzirisa mberi.

7. Easy touch operation ine inobatsira parameter screen

8. 100 zvirongwa zviripo.

-

VPC Series Vacuum Pressure Kukanda Machine yeJewellery

Kudzvinyirira pamusoro peVacuum Casting Machines

VCT imhuri yekudzvinyirirwa pamusoro pemichina yekukanda vacuum yakagadzirirwa kusangana nezvinodiwa zvakanyanya mukurasika kukanda wakisi kugadzirwa kwegoridhe, K-goridhe, mhangura, bhuronzi, alloys. Ivo vanowanzo shandiswa kubatanidza kune 3d printa yekukanda yakananga kuti iwane yekutanga simbi zvikamu zvezvakaoma zvinhu.

Iyi mhuri yemichina inoshanda neitsva, inoshandura kaviri kamuri pfungwa. Iyi innovative system inopa akati wandei mabhenefiti kana ichienzaniswa neyechinyakare single chamber suction system iripo pamusika.

MuVCT, kamuri yekunyunguduka uye kamuri yeflask hazviregi zvachose: paunenge uchikanda, muchina unogona kudzora jekiseni resimbi mu mold nekuisa mutsauko wekumanikidza panguva yekudira. Izvi zvinobereka jekiseni rinokurumidza kana zvichienzaniswa nekungodururwa kwegiravhiti zvine pundutso yekukanda zvinhu pane tembiricha yakaderera. Izvi zvichaguma nekupedzisa kwepamusoro pepamusoro uye kuderedza shrinkage yezvikamu zvakakandwa.Iyo yekukanda kutenderera inotora maminetsi mashoma uye, nepo furasiki yapfuura ichitonhora pasi mukudzivirira gasi pasina oxidation, iyo inotevera inochaja inogona kutakurwa mucrucible uye yakanyungudutswa, nekudaro ichipindirana mavhiri maviri pasina kutambisa nguva.

Muchina uyu unongozviitira otomatiki, une PC yakavakirwa yekutarisa sisitimu yekutora maparamendi ekutora uye kugadzira data manejimendi, ine nyore kugadzirisa kwekukanda zvirongwa zvakakodzera kune akawanda marudzi ealloy.

Uyu muchina weshanduko ndiyo synthesis yeinjiniya yepamusoro uye makore echiitiko mukukandira iyo chete Hasung ichaunza mufekitori yako.