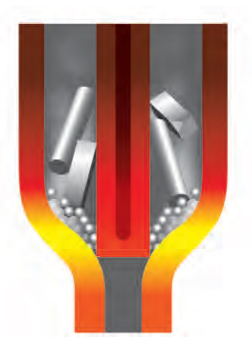

Hasung T2 Jewelry Vacuum Pressure Casting Machine

Sei Iwe Uchisarudza Hasung Vacuum Pressure Casting Machine?

Hasung T2 Vacuum Casting Machines enzanisa nemamwe makambani

1. Kunyatsokandira kuita

2. Kunyungudika kwakanaka. Kunyunguduka kumhanya kuri mukati me2-3 maminetsi.

3. Kukanda kwakasimba kudzvinyirira.

4. Zvikamu zvekutanga zveHasung zvinozivikanwa mabhureki kubva kudzimba, Japan neGermanu.

5. Kunyatsokandira kuita

6. Tsigira 100 chirongwa ndangariro

7. Kuchengetedza magetsi. Nekushandisa kwakaderera simba 10KW 380V 3 chikamu.

8. Kushandisa nitrogen kana argon chete, hapana chikonzero chekubatanidza kune compressor air.

Technical Parameters

| Muenzaniso Nha. | HS-T2 |

| Voltage | 380V, 50/60Hz, 3 zvikamu |

| Magetsi | 10KW |

| Max Temp | 1500°C |

| Nguva yekunyunguduka | 2-3 min. |

| Dziviriro Gasi | Argon / Nitrogen |

| Temp Accuracy | ±1°C |

| Kugona (Goridhe) | 24K: 2.0Kg, 18K: 1.55Kg, 14K: 1.5Kg, 925Ag: 1.0Kg |

| Crucible Volume | 242CC |

| Max flask size | 5"x12" |

| Vacuum Pombi | High quality vacuum pombi |

| Application | Ndarama, K goridhe, sirivheri, mhangura uye mamwe alloys |

| Operation nzira | Kiyi imwe inopedzisa kukanda kwese |

| Kutonhora mhando | Mvura inotonhorera (inotengeswa zvakasiyana) kana Mvura inomhanya |

| Dimensions | 800*600*1200mm |

| Kurema | approx. 230kg |

Product Display

Musoro: Iko Kushanduka kweGoridhe Zvishongo zvekukanda Tekinoroji: Kubva kuMatekinoroji Echinyakare kuenda kuMagadzirirwo Azvino.

Kwemazana emakore, zvishongo zvegoridhe zvave zviri chiratidzo chehupfumi, chimiro uye kunaka. Kubva kumagariro ekare kusvika kufashoni yemazuva ano, kunaka kwegoridhe kunoramba kwakafanana. Imwe yeakakosha maitiro mukugadzira zvishongo zvegoridhe ndeyekukanda, iyo yakashanduka zvakanyanya nekufamba kwenguva. Mubhuku rino, tichaongorora rwendo rwunonakidza rwehunyanzvi hwekukanda zvishongo zvegoridhe, kubva pakuvandudzwa kwayo kusvika kune zvemazuva ano zvekuvandudza.

Tekinoroji Yakare: Kuzvarwa kweGoridhe Kukandwa

Nhoroondo yekukandwa kwegoridhe inogona kurondwa kubva kumagariro ekare seEgypt, Mesopotamia, neChina. Idzi mhizha dzekare dzakagadzira unyanzvi hwokukandira vachishandisa zviumbwa zviri nyore zvakagadzirwa nevhu, jecha, kana dombo. Maitirwo acho anosanganisira kudziyisa goridhe kusvika ranyunguduka wozoidururira muforoma dzakagadzirirwa kugadzira zvishongo.

Nepo idzi nzira dzechinyakare dzaive dzakasimba kwenguva yavo, dzaive dzakaganhurirwa mukururama nekuoma kunzwisisa. Zvishongo zvinobuda zvacho zvinowanzova nechitarisiko chakakasharara uye chakasvibirira, chisina ruzivo rwakanaka uye magadzirirwo akaomarara anoratidza zvishongo zvegoridhe zvemazuva ano.

Kufambira Mberi kweMedieval: Kukura Kwekurasika Wax Kukanda

Munguva yeMiddle Ages, kufambira mberi kukuru muhunyanzvi hwekukanda goridhe kwakaitika nekuvandudzwa kweakarasika tekinoroji yekukanda wakisi. Iyi nzira yakashandura maitiro ekukanda, ichibvumira mhizha kuti dzigadzire zvidimbu zvakaoma uye zvine ruzivo rwezvishongo.

Kukanda wakisi kwakarasika kunosanganisira kugadzira modhi yewakisi yekugadzira zvishongo, izvo zvinozoiswa muforoma yakagadzirwa nepurasita kana ivhu. Mold inodziya, zvichiita kuti wakisi inyunguduke uye inyunguduke, zvichisiya gomba riri muchimiro chemhando yewakisi yepakutanga. Ndarama yakanyungudutswa yaibva yadirwa mugomba, zvichiita kuti pave nemufananidzo chaiwo uye wakadzama wemufananidzo wewakisi.

Iyi tekinoroji yakaratidza kusvetukira kukuru kumberi muhunyanzvi hwekukandira goridhe, ichibvumira mhizha kugadzira zvishongo zvine mapatani akaomarara, basa remafirigree rakapfava, uye manyorerwo akanaka akange asingagoneke.

Industrial Revolution: Mechanized Casting process

Iyo Industrial Revolution yakaunza shanduko yebudiriro yetekinoroji iyo yakashandura maitiro ekugadzira mumaindasitiri akasiyana, kusanganisira kugadzira zvishongo. Munguva iyi, michina yekukanda maitiro akaunzwa, zvichibvumira kugadzirwa kwakawanda kwezvishongo zvegoridhe.

Imwe yeakakosha magadzirirwo aive kuvandudzwa kwemuchina wekukanda wecentrifugal, wakashandisa simba recentrifugal kugovera zvakaenzana goridhe rakanyungudutswa muforoma. Iyi otomatiki maitiro inowedzera zvakanyanya kushanda uye kuenderana kwekukandwa kwegoridhe, zvichikonzera kukwira kwepamusoro uye zvidimbu zvakamisikidzwa zvezvishongo.

Itsva yemazuva ano: dhizaini yedhijitari uye 3D kudhinda

Mumakumi emakore achangopfuura, kubuda kwedhizaini yedhizaini uye tekinoroji yekudhinda ye3D yakashandura mamiriro ekukanda zvishongo zvegoridhe. Izvi zvitsva-zvitsva zvakashandura nzira yekugadzira zvishongo zvekugadzira uye kushandurirwa muzvinhu zvenyama.

Digital dhizaini software inogonesa vagadziri vezvishongo kuti vagadzire akaomesesa e3D modhi neyakajeka isati yamboitika uye ruzivo. Aya mamodheru edhijitari anogona kuzoshandurwa kuita zviratidziro zvemuviri uchishandisa tekinoroji yekudhinda ye3D, iyo inovaka zvishongo dhizaini nedhiza uchishandisa zvakasiyana siyana, kusanganisira wakisi yekukanda.

Iko kushandiswa kwe 3D kudhinda mukukanda zvishongo zvegoridhe kunovhura mikana mitsva yekugadzira yakaoma uye yakagadziridzwa madhizaini ayo aimbove asingagoneke kuburikidza nemaitiro ekukanda nzira. Iyo tekinoroji zvakare inokwenenzvera iyo prototyping uye yekugadzira maitiro, kuderedza nguva dzekutungamira uye kugonesa kukurumidza kudzokororwa kwezvishongo zvekugadzira.

Pamusoro pezvo, kufambira mberi kwemetallurgical uye alloying tekinoroji kwakagonesa kuvandudzwa kwegoridhe nyowani alloys neakakwidziridzwa zvivakwa zvakaita sekuwedzera simba, kusimba, uye shanduko yemavara. Aya maaloyi matsva anowedzera mikana yekugadzira yevagadziri vezvishongo uye vagadziri, vachivabvumira kusunda miganhu yegoridhe rechinyakare jewelry aesthetics.

Remangwana regoridhe rekukanda tekinoroji

Sezvo tekinoroji ichienderera mberi, ramangwana rekukanda zvishongo zvegoridhe rinobata zvimwe zvinonakidza zvingaitika. Ichiri kusimukira matekinoroji akadai sekuwedzera kugadzira uye epamberi marobhoti anotarisirwa kuenderera mberi nekushandura maitiro ekukanda, kuunza mazinga matsva echokwadi, kunyatsoita uye kugadzirisa.

Pamusoro pezvo, kubatanidza hungwaru hwekugadzira uye muchina wekudzidza maalgorithms mukugadzira zvishongo uye kugadzira mafambiro ekufambisa kune mukana wekugadzirisa maitiro ekukanda, kuderedza kutambisa zvinhu, uye kugadzirisa huwandu hwese hwezvishongo zvakapedzwa.

Mukupedzisa, shanduko yehunyanzvi hwekukanda zvishongo zvegoridhe chiratidzo chehunyanzvi uye hunyanzvi hwemhizha uye matekiniki munhoroondo yese. Kubva kuhunyanzvi hwechinyakare hwekukanda wakisi kusvika kune zvinoshamisa zvemazuva ano zvedhizaini uye kudhinda kwe 3D, hunyanzvi hwekukanda goridhe hunoenderera mberi nekushanduka kuzadzisa zvinodiwa zvenguva dzinogara dzichichinja.

Tichitarisa kune ramangwana, zviri pachena kuti kusanganiswa kwehunyanzvi hwechinyakare uye tekinoroji yekucheka-chete icharamba ichigadzira nzvimbo yekukanda zvishongo zvegoridhe, zvichipa mikana isingaperi yekugadzira, kugadzirisa uye kunaka munyika yakanaka yezvishongo.

Vacuum pressure casting machine zvinodyiwa:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic jacket

4. Graphite chivharo

5. Thermocouple

6. Kupisa coil

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur