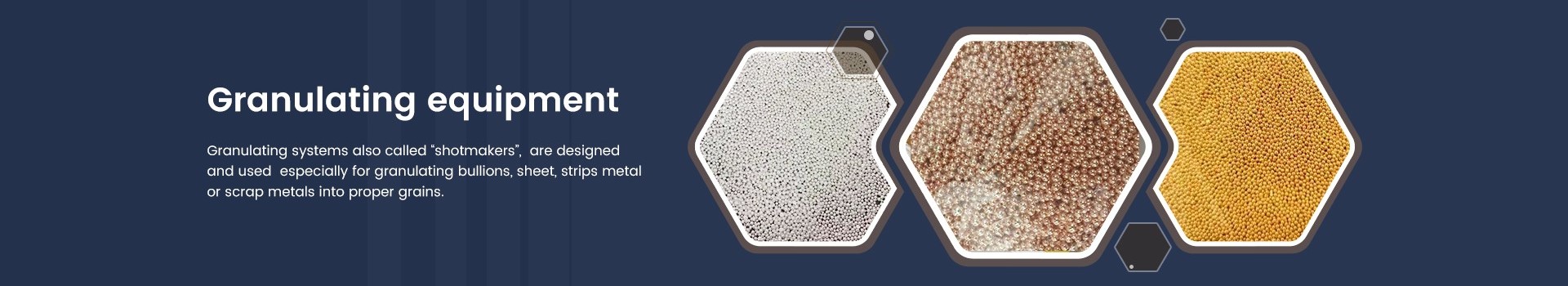

Granulating Systems

Granulating masisitimu anonziwo "vapfuri", akagadzirwa uye anoshandiswa kunyanya kugadzira mabhuru, shizha, simbi kana zvimedu zvimedu kuita zviyo zvakakodzera. Iwo matangi egranulating ari nyore kwazvo kubvisa kuti acheneswe. Dhonza mubato kuti ubvise nyore kwekuisa tangi. Muchina wekusarudza wevacuum pressure casting muchina kana unoenderera mberi uchikanda muchina une tangi regranulating mhinduro yeapo neapo giranulating zvakare. Granulating matangi anowanikwa kune ese mashini ari muVPC akatevedzana. Iyo yakajairwa mhando granulating masisitimu ane tangi ine mavhiri mana ari nyore kufamba mukati nekubuda.

-

Metal Granulator Machine yeGoridhe Silver Copper 4kg 6kg 8kg10kg15kg

1. Nekudzora tembiricha, huchokwadi hunosvika ±1°C.

2. Ultra-human design, kushanda kuri nyore kupfuura vamwe.

3. Shandisa mutungamiriri weMitsubishi anotengeswa kunze kwenyika.

4. Silver Granulator ine tempterature control (Gold Silver Grains Casting Machine, Silver Granulating Machine).

5. Muchina uyu unotora IGBT yepamusoro-soro yekudziya tekinoroji, iyo yekukanda mhedzisiro yakanaka kwazvo, sisitimu yakagadzikana uye yakachengeteka, goridhe rakanyungudutswa rinokwanisa kuita sarudzo, uye iyo granulated simbi yakatarwa ndeyekusarudza.

6. The granulation kumhanya inokurumidza uye hapana ruzha. Yakakwana yepamberi yekuyedza uye yekudzivirira mabasa inoita kuti muchina wese uve wakachengeteka uye wakasimba.

7. Muchina une kupatsanurwa kwekugadzira uye muviri une nzvimbo yakawanda yekusununguka.

-

Platinum Granulating System Granulating Machine 10kg

Hasung Platinum Shot Maker Granulating Machine kana ichienzaniswa neyakafanana zvigadzirwa pamusika, ine isingaenzaniswi yakanakira mabhenefiti maererano nekuita, mhando, chitarisiko, nezvimwewo, uye inonakidzwa nemukurumbira wakanaka mumusika. inovavandudza. Izvo zvinotsanangurwa zveHasung Platinum Shot Maker Granulating Machine inogona kugadzirwa maererano nezvaunoda.

Izvo zvakakosha zvezvizvarwa zvitsva zvemupfuti

Kuiswa nyore kwetangi regranulating nepuratifomu

High quality granulating kuita

Ergonomic uye yakanyatso kurongeka dhizaini yekuchengetedza uye nyore kubata

Yakakwenenzverwa yekuyerera maitiro emvura inotonhorera

Kuparadzaniswa kwakavimbika kwemvura uye granules -

Vacuum Shot Maker yeGoridhe Silver Copper 4kg 8kg 10kg

Dhizaini yeiyi vacuum granulator system yakavakirwa pane izvo chaizvo zvinodiwa zveyakakosha simbi process nekushandisa yemazuva ano yepamusoro-tech induction yekudziya tekinoroji.

Iyo vacuum granulator inoshandiswa kugadzira yakakwira mhando uye homogenous tenzi tsanga dzesimbi dzakakosha segoridhe, sirivheri, mhangura, uye alloys, kutanga kubva pambishi yakanyungudutswa neHasung induction yekudziya mumhepo inert inodzivirira gasi, yobva yadonha mutangi remvura ichipfuura. kuburikidza ne-multi-hollowed crucible iyo inoshanda seyekuyerera.

Iyo vacuum granulator inotora vacuum yakazara uye inert gasi kunyunguduka uye granulating, muchina unogona kuzunguza otomatiki mukunyunguduka, electromagnetic kubvongodza, uye firiji mune yakavharwa + vacuum / inert gasi yekudzivirira inonyunguduka mukamuri, kuitira kuti chigadzirwa chive nehunhu hwekusina oxidation, super. kurasikirwa kwakaderera, pasina pores, hapana kupatsanurwa kwemavara, uye kutaridzika kwakanaka nehukuru hwakafanana.

Mudziyo uyu unoshandisa Mitsubishi PLC chirongwa chekudzora system, SMC pneumatic uye Panasonic servo mota dhiraivha uye zvimwe zvinozivikanwa brand zvinhu kumba nekune dzimwe nyika.

-

Yakakwira Vacuum Granulating System yeGoridhe Silver Copper 20kg 50kg 100kg

High vacuum granulator granulates inokosha simbi particles yekukanda bonding waya: goridhe, sirivheri nemhangura, bonding waya inonyanya kushandiswa semiconductor zvinhu, photovoltaic welding zvinhu, mishonga yekurapa, artificial intelligence machines.Uyewo aya epamusoro vacuum metal shotmakers anogadzirwa kunyanya kugadzira mabhuru. , simbi, kana zvimedu kuita tsanga dzakafanira. Iwo matangi egranulating ari nyore kwazvo kubvisa pakuchenesa. Iwo HS-VGR High Vacuum Granulating Machines anowanikwa ane crucible capacity kubva pa20kg kusvika pa100kg. Zvishandiso zvemuviri zviri kushandisa 304 simbi isina tsvina iyo inovimbisa kunaka kwehupenyu hurefu uchishandisa, zvakare ine modular dhizaini kuzadzisa mhando inodiwa.

Zvikumbiro zvikuru:

1. Kugadzirira kwema alloys kunze kwegoridhe uye master alloy

2. Kugadzirira kwezvikamu zvealloy

3. Kugadzirira kwema alloys kubva kune zvikamu

4. Kucheneswa kwesimbi yakakandwa kare

5. Kugadzira zviyo zvesimbi zvekutengesa simbi inokoshaVGR yakatevedzana yakagadziridzwa kugadzirwa kwesimbi granules ine saizi yezviyo pakati pe1.5 mm ne4mm. Iwo masisitimu akavakirwa paHasung granulation units, asi zvese zvakakosha zvikamu, kunyanya jet system, zviitiko zvakakosha.

Iyo hombe yakakura senge 100kg vacuum granulating system inosarudzika kuve neyakagadzirirwa Mitsubishi PLC Kubata Panel control system.

Iyo inosarudzika midziyo yevacuum pressure kana inoenderera mberi yekukanda muchina ine granulating tank ndiyo yakakodzera mhinduro yeapo neapo granulating. Granulating matangi anowanikwa kune ese mashini ari muVC akateedzana.

Zvakanakisa zvakanakira zvizvarwa zvitsva zvepfuti:

1. Kuiswa nyore kwetangi yegranulating

2. Kukurumidza-kuchinja pakati pekukanda maitiro uye granulating

3. Ergonomic uye yakanyatsogadzirisa dhizaini kuitira kuchengetedza uye nyore kubata

4. Optimized kuyerera maitiro emvura inotonhorera

5. Kuparadzaniswa kwakavimbika kwemvura uye granules

6. Iyo yakanyanya simba uye inoshanda kune akakosha masimbi ekunatsa mapoka.

7. Kuchengetedza simba, kukurumidza kunyunguduka. -

Metal Granulating Machine yeGoridhe Silver Copper Alloy 20kg 30kg 50kg 100kg 150kg

1. Nekudzora tembiricha, huchokwadi hunosvika ±1°C.

2. Ultra-human design, kushanda kuri nyore kupfuura vamwe.

3. Shandisa mutungamiriri weMitsubishi anotengeswa kunze kwenyika.

4. Silver Granulator ine tempterature control (Gold Silver Grains Casting Machine, Silver Granulating Machine).

5. Muchina uyu unotora IGBT yepamusoro-soro yekudziya tekinoroji, iyo yekukanda mhedzisiro yakanaka kwazvo, sisitimu yakagadzikana uye yakachengeteka, goridhe rakanyungudutswa rinokwanisa kuita sarudzo, uye iyo granulated simbi yakatarwa ndeyekusarudza.

6. The granulation kumhanya inokurumidza uye hapana ruzha. Yakakwana yepamberi yekuyedza uye yekudzivirira mabasa inoita kuti muchina wese uve wakachengeteka uye wakasimba.

7. Muchina une kupatsanurwa kwekugadzira uye muviri une nzvimbo yakawanda yekusununguka.

-

Compact size Metal Granulator Granulating Equipment for Gold Silver

Small size metal shotmakers. Nekudzora tembiricha, huchokwadi hunosvika ± 1°C.

Ultra-munhu dhizaini, kushanda kuri nyore kupfuura vamwe.

Shandisa chidhiraivho cheMitsubishi kubva kunze kwenyika.Muchina uyu unotora Germany IGBT yepamberi yekudziya tekinoroji, iyo yekukanda mhedzisiro yakanaka kwazvo, sisitimu yakagadzikana uye yakachengeteka, goridhe rakanyungudutswa rinogoneka, uye iyo granulated simbi yakatarwa ndeyekusarudza. Iyo granulation kumhanya inokurumidza uye hapana ruzha. Yakakwana yepamberi yekuyedza uye yekudzivirira mabasa inoita kuti muchina wese uve wakachengeteka uye wakasimba. Muchina uyu une dhizaini yekuparadzanisa uye muviri une nzvimbo yemahara.

Kushandisa isina mhepo compressor, kukanda nemaoko mechanicha yekuvhura chivharo.

Iyi GS Series granulating system inokodzera diki diki kubva pa1kg kusvika 8kg kugona (goridhe), yakanakira vatengi vane nzvimbo diki.

Chii chinonzi metal granulation?

Granulation (kubva muchiLatin: granum = “zviyo”) inyanzvi yemupfuri wegoridhe apo pamusoro pechishongo chinoshongedzwa netunhu tudiki twesimbi yakakosha, inonzi magranules, zvichienderana nedhizaini patani. Zvitsva zvekare zvekuchera matongo zvematombo akaitwa nehunyanzvi uhu zvakawanikwa mumakuva ehumambo eUri, kuMesopotamia uye kudzokera ku2500 BC Kubva munzvimbo iyi, nzira iyi yakapararira kuAnatolia, kuSyria, kuTroy (2100 BC) uye pakupedzisira kuEtruria. (zana remakore rechisere BC). Kwakanga kuri kunyangarika zvishoma nezvishoma kwetsika dzeEtruscan pakati pezana ramakore rechitatu nerechipiri BC ndiko kwakakonzera kudzikira kwegranulation.1 MaGiriki ekare aishandisawo basa regranulation, asi mhizha dzeEtruria dzakava nemukurumbira nekuda kwehunyanzvi uhu nekuda kutumirwa kwavo kusinganzwisisike kwehupfu hwakatsetseka granulation2 pasina kuoneka kushandiswa kwehard solder.

Granulation ingangove isinganzwisisike uye inonakidza yemaitiro ekare ekushongedza. Yakaunzwa nemhizha Fenici naGreci kuEtruria muzana ramakore rechisere BC, uko ruzivo rwesimbi uye kushandiswa kwesimbi dzakakosha zvakange zvatove padanho repamusoro, nyanzvi yeEtruscan vapfuri vegoridhe vakaita nzira iyi yavo kugadzira mabasa eumhizha hwekuoma kusingaenzaniswi uye runako.

Mukati mehafu yekutanga yemakore ekuma1800 mafukuro akati wandei akaitwa munharaunda yeRoma (Cerveteri, Toscanella neVulci) uye Maodzanyemba kweRussia (iyo Kertch neTaman peninsulas) yakaratidza zvishongo zvekare zveEtruscan neGreek. Zvishongo izvi zvakashongedzwa negranulation. Zvishongo zvakauya kune veCastellani Mhuri yezvishongo vaibatanidzwa zvakanyanya mukutsvakurudza kwezvishongo zvekare. Zvakawanikwa kubva kunzvimbo dzekuvigwa dzeEtruscan zvakakwezva kutarisisa zvakanyanya nekuda kwekushandisa kwavo magranules akanyanya kunaka. Alessandro Castellani akadzidza zvinhu izvi zvakadzama kuti aedze kuburitsa nzira yavo yekugadzira. Yakanga isiri kusvika pakutanga kwezana ramakore rechi20, mushure mekufa kwaCastellani, iyo pikicha yecolloidal / eutectic soldering yakagadziriswa.

Kunyange zvazvo chakavanzika chakaramba chiri chakavanzika kune veCastellanis nevairarama navo, zvishongo zvichangobva kuwanikwa zveEtruscan zvakakonzera rumutsiridzo rwezvishongo zvekuchera matongo kuma1850. Nzira dzekugadzira goridhe dzakawanikwa dzakagonesa Castellani nevamwe kuti vakwanise kuberekazve zvimwe zvezvishongo zvekare zvakanakisa zvakambocherwa. Mazhinji ehunyanzvi uhu hwakanga hwakasiyana neaya akashandiswa neveEtruscans asi achiri kuburitsa mhedzisiro. Zvizhinji zveizvi Archaeological Revival jewelry zvinhu zvino mune zvakakosha zvishongo zvekuunganidza pasi rose, pamwe chete nevamwe vavo vekare.

GRANULES

Iyo granules inogadzirwa kubva kune imwechete alloy sesimbi iyo iyo ichashandiswa. Imwe nzira inotanga nekuburitsa bepa rakatetepa resimbi uye kukwesha mipendero yakatetepa kwazvo kumucheto. Mupendero wakachekwa uye mhedzisiro yacho madiki madiki kana maplatelet esimbi. Imwe nzira yekugadzira zviyo inoshandisa waya yakatetepa yakavharidzirwa yakatenderedza mandrel yakatetepa, senge tsono. Koiri inozochekwa kuita zvindori zvidiki zvekusvetuka. Izvi zvinogadzira zvindori zvakaenzanirana izvo zvinoita kuti pave nemagranules akaenzana. Chinangwa ndechekugadzira mativi akawanda akaenzana saizi ine dhayamita isingapfuuri 1 mm.

Maplatelet esimbi kana zvindori zvekusvetuka zvakaputirwa nehupfu hwemarasha kudzivirira kunamatirana panguva yekupfurwa. Pasi pechibhorani chakafukidzwa nemarasha uye masimbi esimbi anosaswa kuitira kuti aenzane sezvinobvira. Izvi zvinoteverwa nehutsva hutsva hwehupfu hwemarasha uye zvimwe zvimedu zvesimbi kusvikira crucible inenge mitatu-matatu izere. Iyo crucible inotungidzwa muchoto kana muhovhoni, uye zvidimbu zvesimbi zvakakosha zvinopinda muzvikamu zvidiki pakunyungudika kwekushisa kwealloy yavo. Aya mativi achangobva kugadzirwa anosiiwa kuti atonhore. Gare gare ivo vanocheneswa mumvura kana, kana nzira yekusimbisa ichashandiswa, yakabikwa muasidhi.

Magranules ehukuru husina kuenzana haakwanise kugadzira dhizaini inofadza. Sezvo zvisingagoneki kuti mupfuri wegoridhe agadzire mativi akaenzana ehupamhi hwakafanana, magranules anofanira kurongwa asati ashandiswa. Mutsara wemasefa anoshandiswa kugadzirisa magranules.

Unogadzira sei goridhe shoti?

Maitiro ekugadzira goridhe kupfura ari kungodurura goridhe rakanyungudutswa zvishoma nezvishoma mumvura mushure mekunge wapisa? Kana kuti unozviita zvose panguva imwe chete? Chii chinangwa chekugadzira goridhe kupfura pane ingots ect.

Kupfurwa kwegoridhe hakugadzirike nekudurura kubva pamuromo wegaba. Inofanira kubudiswa kuburikidza ne nozzle. Unogona kugadzira iri nyore nekuboora kaburi kadiki (1/8") pasi pedhishi rinonyunguduka, rinobva raiswa pamusoro pegaba rako remvura, mwenje uchirira pandiro, uchitenderedza gomba. iyo goridhe kubva muchando mundiro painotamiswa kubva mundiro yakanyunguduka umo hupfu hwegoridhe hunonyungudutswa nezvikonzero zvagara zvakandiomera kuti ndinzwisise, izvo zvinoumba kupfurwa, panzvimbo yezviyo.

Shot inosarudzwa nevaya vanoshandisa goridhe, nekuti inoita kuti kuyera huwandu hunodiwa kuve nyore. Vapfuri vegoridhe vakachenjera havanyungudise goridhe rakawanda panguva imwe chete, zvikasadaro zvinogona kutungamirira mukukandwa kusina kukwana (gas inclusions).

Nekunyungudutsa chete huwandu hunodiwa, iyo diki yasara (sprue) inogona kunyungudutswa nebatch rinotevera, kuvimbisa kuti goridhe rakanyungudutswa hariunganidzi.

Dambudziko rekunyungudusa goridhe nguva nenguva nderekuti simbi yepasi (kazhinji mhangura, asi isina kuganhurirwa kumhangura) inoisa oxidize uye inotanga kugadzira gasi rinoungana muhomwe diki mukukanda. Zvizhinji zvishongo zvese zvinokandira zvakave nechiitiko ichocho, uye kazhinji zvinoverengera kuti nei vasingadi, kana kusada kushandisa goridhe rakamboshandiswa kare.