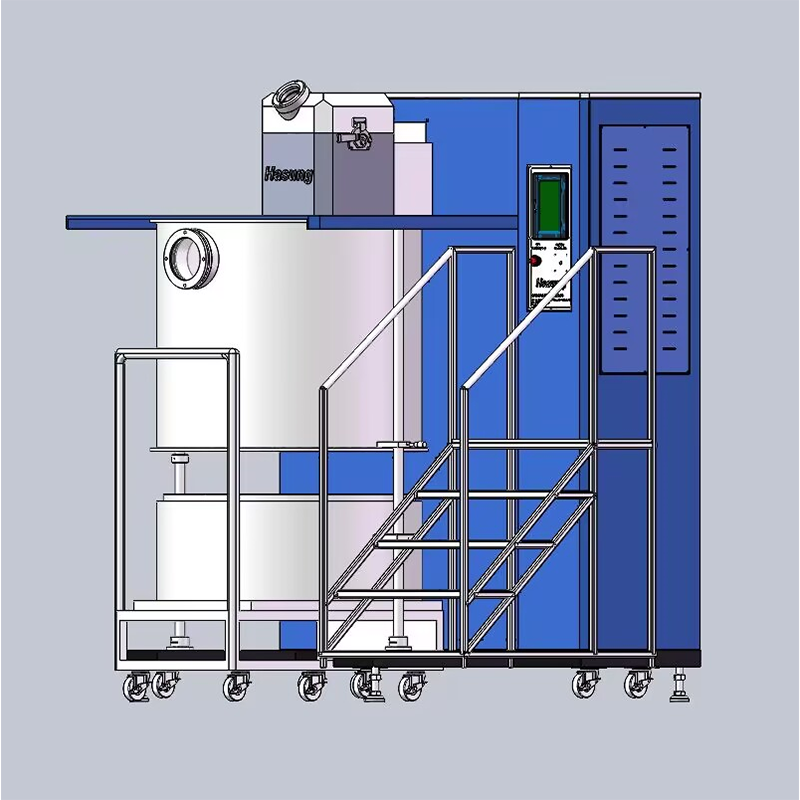

100 mesh - 400 mesh Metal Powder Mvura Atomizer Machine

Technical Parameters

| Muenzaniso Nha. | HS-MGA5 | HS-MGA10 | HS-MGA30 | HS-MGA50 | HS-MGA100 |

| Voltage | 380V 3 Zvikamu, 50/60Hz | ||||

| Magetsi | 15KW | 30KW | 30KW/50KW | 60KW | |

| Kugona (Au) | 5kg | 10kg | 30kg | 50kg | 100kg |

| Max Temp. | 1600°C/2200°C | ||||

| Nguva yekunyunguduka | 3-5 min. | 5-8 min. | 5-8 min. | 6-10 min. | 15-20 min. |

| Particle zviyo (Mesh) | 200#-300#-400# | ||||

| Temp Accuracy | ±1°C | ||||

| Vacuum Pombi | Yepamusoro yemhando yepamusoro vacuum degree vacuum pombi | ||||

| Ultrasonic system | High quality Ultrasonic system control system | ||||

| Operation nzira | Imwe-kiyi oparesheni yekupedzisa hurongwa hwese, POKA YOKE foolproof system | ||||

| Kudzora System | Mitsubishi PLC+Munhu-muchina interface intelligent control system | ||||

| Inert gasi | Nitrogen/Argon | ||||

| Kutonhora mhando | Chiller yemvura (inotengeswa zvakasiyana) | ||||

| Dimensions | approx. 3575*3500*4160mm | ||||

| Kurema | approx. 2150kg | approx. 3000kg | |||

Atomization pulverizing nzira inzira nyowani yakagadziridzwa muindasitiri yehupfu simbi mumakore achangopfuura. Iyo ine zvakanakira maitiro akareruka, nyore tekinoroji kugona, zvinhu zvisiri nyore kuve oxidized, uye yakakwirira degree re automation.

1. Iyo chaiyo nzira ndeyokuti mushure mokunge alloy (simbi) yakanyungudutswa uye yakanatswa muchoto chekupinza, mvura yakanyungudutswa yesimbi inodururwa mu crucible yekuchengetedza kupisa uye inopinda muchubhu yemutungamiri uye nozzle. Panguva ino, kunyunguduka kuyerera kunovharwa ne-high-pressure fluid kuyerera (kana gasi kuyerera) Iyo atomized uye atomized simbi poda inosimbiswa uye inogadzika muatomization tower, uye yobva yawira muhupfu hwekuunganidza tangi yekuunganidza uye kupatsanurwa. Inoshandiswa zvakanyanya mumunda weusina-ferrous simbi poda kugadzira senge atomized iron poda, mhangura yemhangura, Stainless simbi poda uye alloy poda. Tekinoroji yekugadzira yemaseti akazara emidziyo yehupfu yesimbi, midziyo yehupfu yemhangura, midziyo yehupfu yesirivheri uye alloy poda michina iri kuramba ichikura.

2. Kushandisa uye musimboti wemvura atomization pulverizing midziyo, mvura atomization pulverizing mudziyo mudziyo wakagadzirirwa kusangana kugadzirwa kwemvura atomization pulverizing maitiro pasi pemamiriro emuchadenga, uye iindasitiri ine maindasitiri akawanda kugadzira mudziyo. Nheyo yekushanda yemvura atomization pulverizing equipment inoreva kunyungudutswa kwesimbi kana simbi alloy pasi pemamiriro emuchadenga. Pasi pemamiriro ekuchengetedzwa kwegasi, iyo simbi yesimbi inoyerera kuburikidza neinopisa yekudzivirira tundish uye pombi yekuchinjisa, uye iyo yekupedzisira-yakanyanya kudzvanywa mvura inoyerera nemumuromo. Iyo simbi yemvura inogadzirwa neatomu uye yakaputsika kuita nhamba huru yemadonhwe esimbi yakanaka, uye madonhwe akatsetseka anoita sub-spherical kana irregular particles pasi pechiito chakabatanidzwa chekushushikana kwepamusoro uye nekukurumidza kutonhora kwemvura panguva yekubhururuka kuzadzisa chinangwa chekugaya.

3. Mvura yeatomization pulverizing midziyo ine zvinotevera maitiro: 1. Inogona kugadzirira yakawanda yesimbi uye ayo alloy powder, uye mari yekugadzira yakaderera. 2. Subspherical poda kana poda isina kukwana inogona kugadzirirwa. 3. Nekuda kwekukurumidza kusimba uye pasina kupatsanurwa, akawanda akakosha alloy powders anogona kugadzirirwa. 4. Nekugadzirisa nzira yakakodzera, hupfu hwehupfu hunogona kusvika kune hunodiwa hunodiwa.

4. Chimiro chemvura atomization pulverizing midziyo Chimiro chemvura atomizing pulverizing midziyo ine zvinotevera zvikamu: kunyunguduka, tundish system, atomization system, inert gasi rekudzivirira system, Ultra-yakakwirira pressure mvura system, kuunganidzwa kweupfu, kupera simba uye kuomesa system, screening system, inotonhora mvura system, PLC control system, platform system, etc. 1. Melting uye tundish system: Kutaura zvazviri, i yepakati frequency induction yekunyungudutsa vira, iyo inosanganisira: ganda, induction coil, tembiricha yekuyera mudziyo, tilting choto mudziyo, tundish uye zvimwe zvikamu: iyo goko chimiro chefuremu, inova kabhoni Yakagadzirwa nesimbi uye simbi isina tsvina, induction coil inoiswa. pakati, uye crucible inoiswa mu induction coil, iyo inogona kunyungudutswa uye kudirwa. Iyo tundish inoiswa pane iyo nozzle system, inoshandiswa kuchengetedza yakanyungudutswa yesimbi mvura, uye ine basa rekuchengetedza kupisa. Iyo idiki pane crucible ye smelting system. Iyo tundish inobata choto ine yayo yekudziya system uye tembiricha yekuyera system. Iyo yekudziya sisitimu yechoto chekubata ine nzira mbiri: kupokana kupisa uye kupisa induction. Iyo yekupisa yekupisa tembiricha inogona kazhinji kusvika 1000 ℃, uye induction yekudziya tembiricha inogona kusvika 1200 ℃ kana kupfuura, asi iyo crucible zvinhu zvinofanirwa kusarudzwa zvine musoro. 2. Atomization system: Iyo atomization system ine ma nozzles, high-pressure water pombi, mavharuvhu, etc. 3. Inert gasi kudzivirira system: Mukuita pulverizing, kuitira kuderedza oxidation yesimbi uye alloys uye kuderedza okisijeni. yehupfu, imwe huwandu hwegasi inert inowanzounzwa mushongwe yeatomization yekuchengetedzwa kwemhepo. 4. Ultra-high-pressure water system: Iyi sisitimu mudziyo unopa yakanyanya-kudzvanywa mvura yeatomizing nozzles. Inosanganisira pombi dzemvura dzakanyanya-kudzvanywa, matangi emvura, mavharuvhu, mahosi ekumanikidza uye mabhasi. 5. Kutonhodza system: Chigadzirwa chacho chose chine mvura inotonhorera, uye iyo inotonhorera inokosha. Tembiricha yemvura inotonhorera icharatidzwa pane yechipiri chiridzwa kuti ive nechokwadi chekushanda kwakachengeteka kwechigadzirwa. 6. Kudzora sisitimu: Iyo yekudzora sisitimu ndiyo inobata nzvimbo yekudzora mudziyo. Kwese mashandiro uye data rakabatana rinoendeswa kuPLC yehurongwa, uye mhedzisiro inogadziriswa, inochengetwa uye inoratidzwa kuburikidza nekushanda.

R&D uye kugadzirwa kwehunyanzvi hwekugadzira midziyo yehupfu hutsva, ichipa nyanzvi dzakatevedzana mhinduro dzekugadzirwa kwezvinhu zvitsva zvehupfu, spherical poda yekugadzira tekinoroji ine yakazvimirira yehungwaru kodzero / kutenderera uye flat poda yekugadzira tekinoroji / strip poda yekugadzira tekinoroji / flake. tekinoroji yekugadzira hupfu, pamwe neiyo ultrafine/nano poda yekugadzira tekinoroji, yakakwira kemikari kuchena poda yekugadzira tekinoroji.

Maitiro Ekugadzira Metal Powder NeMvura Atomization Pulverizing Equipment

Maitiro ekugadzira simbi hupfu nemvura atomization pulverizing midziyo ine nhoroondo refu. Munguva dzekare, vanhu vaidira simbi yakanyungudutswa mumvura kuti iputse musimbi yakanaka kwazvo, iyo yaishandiswa sezvinhu zvokugadzira simbi; kusvika zvino, kuchine vanhu vanodira mutobvu wakanyungudutswa zvakananga mumvura kuti vagadzire mapeteti emutobvu. . Uchishandisa nzira yeatomization yemvura kugadzira coarse alloy poda, iyo process musimboti yakafanana neyataurwa pamusoro pemvura inoputika simbi yemvura, asi iyo pulverization inoshanda yakagadziridzwa zvakanyanya.

Iyo mvura atomization pulverizing midziyo inogadzira coarse alloy poda. Kutanga, goridhe rakagosha rinonyungudutswa muchoto. Iyo yakanyungudutswa yegoridhe mvura inofanirwa kupiswa neanenge 50 madhigirii, uye yozodururwa mu tundish. Tanga iyo yepamusoro-inodzvinyirira mvura pombi isati yaiswa goridhe mvura, uye rega iyo yepamusoro-inomanikidza mvura atomization mudziyo utange iyo workpiece. Mvura yegoridhe iri mu tundish inopfuura nepadanda yopinda muatomizer nemumuromo unobvinza uri pazasi pe tundish. Atomizer ndiyo yakakosha midziyo yekugadzira coarse goridhe alloy poda nepamusoro-inomanikidza mvura mhute. Hunhu hweatomizer hunoenderana nekupwanya kwehupfu hwesimbi. Pasi pekuita kwemvura yakakwira-kudzvanywa kubva kuatomizer, iyo yegoridhe mvura inoramba yakapwanyika kuita madonhwe akatsetseka, ayo anowira mumvura inotonhorera mumudziyo, uye mvura inokurumidza kuoma kuita alloy poda. Muchinyakare nzira yekugadzira simbi poda nepamusoro-kudzvinyirira mvura atomization, iyo simbi poda inogona kuunganidzwa nguva dzose, asi pane mamiriro ezvinhu ekuti hushoma hwesimbi hupfu hunorasika nemvura yeatomizing. Mukuita kugadzira alloy poda nepamusoro-kudzvanywa kwemvura atomization, chigadzirwa cheatomi chakaiswa mumudziyo weatomization, mushure mekunaya, kusefa, (kana zvichidikanwa, inogona kuomeswa, kazhinji inotumirwa zvakananga kune inotevera maitiro.) yakanaka Alloy poda, hapana kurasikirwa kwealloy poda mukuita kwese.

Seti yakakwana yemvura atomization pulverizing zvishandiso Zvishandiso zvekugadzira alloy poda ine zvikamu zvinotevera:

Chikamu chekunyungudutsa:yepakati-frequency simbi yekunyungudutsa choto kana yakakwira-frequency simbi yekunyungudutsa vira inogona kusarudzwa. Kugona kwechoto kunotarirwa maererano nehuwandu hwekugadzirisa hupfu hwesimbi, uye 50 kg yevira kana 20 kg yevira inogona kusarudzwa.

Atomization chikamu:Midziyo iri muchikamu ichi isiri-yakajairwa midziyo, iyo inofanirwa kugadzirwa uye kurongeka zvinoenderana nesaiti mamiriro emugadziri. Iko kune kunyanya tundishes: apo tundish inogadzirwa munguva yechando, inoda kuve yakatsva; Atomizer: Iyo atomizer ichauya kubva pakudzvanywa kwepamusoro Mvura yepombi inobata mvura yegoridhe kubva pa tundish nekumhanya kwakafanotemerwa uye kona, ichiipwanya kuita madonhwe esimbi. Pasi pesimba repombi yemvura yakafanana, huwandu hwehupfu hwesimbi yakatsetseka mushure meatomization hune hukama neatomizer kushanda kweatomizer; iyo atomization cylinder: inzvimbo iyo alloy poda inogadziriswa, yakapwanyika, inotonhorera uye inounganidzwa. Kuti udzivirire ultra-fine alloy powder mune yakawanikwa alloy poda kubva pakurasikirwa nemvura, inofanira kusiiwa kwenguva yakati mushure meatomization, uye yozoiswa mubhokisi rekuunganidza hupfu.

Post-processing chikamu:bhokisi rekuunganidza poda: rinoshandiswa kuunganidza iyo atomize alloy poda uye kuparadzanisa uye kubvisa yakawandisa mvura; kuomesa choto: omesa upfu hwakanyorova nemvura; muchina wekuongorora: sieve iyo alloy poda, Kunze-kwe-kutsanangurwa coarser alloy poda inogona kunyungudutswa zvakare uye neatomu sechinhu chekudzoka.

Vacuum Air Atomization Pulverizing Technology And Its Application

Iyo poda inogadzirwa nevacuum air atomization ine zvakanakira kuchena kwakanyanya, yakaderera oksijeni yemukati uye yakanaka poda particle size. Mushure memakore ekuenderera mberi kwekuvandudza nekuvandudza, vacuum air atomization poda tekinoroji yakave nzira huru yekugadzira yakakwirira-inoshanda simbi uye alloy hupfu, uye yave chinhu chinotungamira chinotsigira nekusimudzira tsvakiridzo yezvishandiso zvitsva uye kuvandudzwa kwemichina mitsva. Mupepeti akaunza musimboti, maitirwo uye poda yekugaya midziyo yevacuum air atomization, uye akaongorora mhando uye mashandisiro ehupfu hwakagadzirirwa nevacuum air atomization.

Nzira yeatomization inzira yekugadzira hupfu umo mvura inofamba inokurumidza (atomizing medium) inokanganisa kana neimwe nzira inopwanya simbi kana alloy fluid kuita madonhwe akatsetseka, anozokombwa kuita hupfu hwakasimba. Iyo atomized powder particles haingove neiyo chaiyo homogeneous kemikari yakagadzirwa seyakapihwa yakanyungudutswa alloy, asiwo nekuda kwekukurumidza kusimba kunonatsa chimiro chekristaro uye inobvisa macrosegregation yechikamu chechipiri. Iyo inowanzoshandiswa atomization yepakati imvura kana ultrasonic, iyo inonzi mvura atomization uye gasi atomization saizvozvo. Mishonga yesimbi yakagadzirwa neatomization yemvura ine goho rakakwirira uye hupfumi hwehupfumi, uye chiyero chekutonhora chinokurumidza, asi mapeji ane okisijeni yakawanda uye irregular morphology, kazhinji flakes. Iyo poda yakagadzirwa ne ultrasonic atomization tekinoroji ine diki diki saizi, yakakwira sphericity uye yakaderera oksijeni yemukati, uye yave nzira huru yekugadzira yakakwirira-inoshanda spherical simbi uye alloy poda.

Vacuum kunyungudutsa yakakwirira-kumanikidza gasi atomization pulverizing tekinoroji inobatanidza yakakwira-vacuum tekinoroji, yakakwirira-tembiricha yekunyungudutsa tekinoroji, yakanyanya-kudzvanywa uye inomhanyisa gasi tekinoroji, uye inogadzirwa kuti isangane nezvinodiwa zvehupfu metallurgy kusimudzira, kunyanya kugadzirwa kwepamusoro-. mhando alloys ane inoshanda zvinhu upfu. Ultrasonic / Gasi atomization pulverizing tekinoroji ndiyo nyowani inokurumidza kusimba tekinoroji. Nekuda kwekutonhora kwakanyanya, hupfu hune hunhu hwekunatsa zviyo, yunifomu kuumbwa uye yakakwirira yakasimba solubility.

Mukuwedzera kune zvakanakira zviri pamusoro, iyo simbi poda inogadzirwa nevacuum smelting high-pressure gas atomization ine maitiro matatu anotevera: pure powder, low oxygen content; zvibereko zvakawanda zvehupfu hwakatsetseka; high kuonekwa sphericity. Zvimiro kana zvinoshanda zvakagadzirwa kubva paupfu uhu zvine zvakawanda zvakanakira pamusoro pezvakajairwa zvinhu maererano nemuviri uye makemikari zvimiro. Mapoda akagadzirwa anosanganisira superalloy poda, thermal spray alloy poda, copper alloy poda uye stainless steel poda.

1 Vacuum air atomization poda yekugaya maitiro uye zvishandiso

1.1 Vacuum air atomization poda yekugaya maitiro

Iyo vacuum air atomization pulverizing nzira imhando nyowani yemaitiro akagadzirwa muindasitiri yekugadzira simbi yehupfu mumakore achangopfuura. Iyo ine zvakanakira zvisiri nyore oxidation yezvinhu, kukurumidza kudzima kwesimbi hupfu, uye yakakwirira degree re automation. Iyo chaiyo maitiro ndeyekuti mushure mekunge alloy (simbi) yanyungudutswa uye yakanatswa muchoto chekupinza, iyo yakanyungudutswa simbi yemvura inodururwa mukati mekupisa kwekunyungudika kwekushisa, uye inopinda muchubhu yekutungamira uye nozzle, uye kunyungudika kunyunguduka kunoitwa atomi nepamusoro- pressure gasi kuyerera. Iyo atomized simbi poda inoomesa uye inogara muatomization tower, uye inowira muhupfu hwekuunganidza tangi.

Atomizing midziyo, atomizing ultrasonic uye simbi mvura inoyerera ndiwo matatu akakosha maficha egasi atomization maitiro. Mumidziyo yeatomization, iyo jekiseni atomizing ultrasonic inomhanyisa uye inopindirana neyakajairwa simbi yemvura inoyerera kuti igadzire munda wekuyerera. Mundima inoyerera inoyerera, simbi yakanyungudutswa inoyerera inotyoka, yakatonhodzwa uye yakasimbiswa, nokudaro ichiwana hupfu hune humwe hunhu. Iwo maparamendi emidziyo yeatomization anosanganisira nozzle chimiro, catheter chimiro, catheter chinzvimbo, nezvimwewo, atomization gasi uye maitiro ayo paramita anosanganisira ultrasonic zvivakwa, air inlet pressure, air velocity, nezvimwewo, uye simbi yemvura inoyerera uye maitiro ayo maparamita anosanganisira simbi kuyerera kwemvura. zvivakwa, superheat, mvura inoyerera dhayamita, etc. Ultrasonic atomization inozadzisa chinangwa chekugadzirisa hupfu particle size, particle size distribution uye microstructure nekugadzirisa zvakasiyana-siyana maparameter uye avo. coordination.

1.2 Vacuum air atomization pulverizing midziyo

Iyo yazvino vacuum atomization pulverizing michina inonyanya kusanganisira yekunze midziyo uye zvemumba. Midziyo inogadzirwa kunze kwenyika ine kugadzikana kwepamusoro uye kurongeka kwepamusoro, asi mutengo wemidziyo wakakwira, uye mutengo wekugadzirisa nekugadzirisa wakakwira. Mutengo wemidziyo yemumba wakaderera, mutengo wekugadzirisa wakaderera, uye kugadzirisa kuri nyore. Nekudaro, vagadziri vemidziyo yemumba kazhinji havagone epakati matekinoroji emidziyo yakadai seatomizing nozzles uye maitiro eatomization. Parizvino, masangano akakodzera ekutsvagisa ekunze uye mabhizinesi ekugadzira anochengeta tekinoroji yakavanzika, uye yakananga uye maindasitiri maitiro maparamita haagone kuwanikwa kubva kune akakodzera mabhuku uye patent. Izvi zvinoita kuti goho rehupfu hwepamusoro-soro huve hushoma kuti huve nehupfumi, iyo ndiyowo chikonzero chikuru nei nyika yangu isati yakwanisa kubudisa hupfu hwepamusoro-soro kunyange zvazvo kune akawanda aerosol powder production uye masayenzi ekutsvakurudza zvikamu.

Chimiro cheiyo ultrasonic atomization pulverizing mudziyo ine zvinotevera zvikamu: yepakati frequency induction induction melting vira, inobata choto, atomization system, atomization tank, guruva rekuunganidza system, ultrasonic supply system, mvura inotonhorera system, control system, nezvimwe.

Parizvino, tsvakiridzo dzakasiyana dzeaerosolization dzinonyanya kutarisa pazvinhu zviviri. Kune rimwe divi, ma parameter eiyo nozzle chimiro uye hunhu hwekuyerera kwejeti zvinodzidzwa. Chinangwa ndechekuwana hukama pakati penzvimbo yekuyerera kwemhepo uye chimiro chenozzle, kuitira kuti iyo ultrasonic isvike pakumhanya pamhepo yekubuda nepo ultrasonic flow rate iri diki, uye inopa hwaro hwe theoretical hwekugadzira nekugadzirisa muromo. Kune rumwe rutivi, hukama pakati peatomization process parameters uye hupfu hwehupfu hwakadzidzwa. Inovavarira kudzidza mhedzisiro yeatomization process paramita pane hupfu zvivakwa uye atomization kunyatsoshanda pane nozzle-chaiyo hwaro hwekugadzirisa uye kutungamira kugadzirwa kwehupfu. Mushoko, kuvandudza kugadzirwa kwehupfu hwakatsetseka uye kuderedza kushandiswa kwegasi kunotungamira kutungamira kweiyo ultrasonic atomization tekinoroji.

1.2.1 Mhando dzakasiyana dzemanozzles e ultrasonic atomization

Iyo atomizing gasi inowedzera kukurumidza uye simba kuburikidza nemuromo, nekudaro zvinobudirira kutyora simbi yemvura uye kugadzira hupfu hunoenderana nezvinodiwa. Iyo muromo inodzora kuyerera uye kuyerera patani yeatomized svikiro, uye inoita basa rakakosha padanho reatomization kunyatsoita uye kugadzikana kweiyo atomization maitiro, uye ndiyo yakakosha tekinoroji yeultrasonic atomization. Mukutanga gasi atomization maitiro, iyo yemahara-inodonha nozzle chimiro chaiwanzo shandiswa. Iyi muromo yakapfava mukugadzira, haisi nyore kuvharika, uye maitiro ekudzora ari nyore, asi ayo atomization inoshanda haina kukwirira, uye inokodzera chete kugadzirwa kwehupfu ine particle size ye50-300 μm. Kuti uvandudze kushanda kweatomization, mapfumo anodzivirira kana atomikisi akanyatsobatanidzwa nozzles akagadzirwa gare gare. Iyo yakasimba kana inorambidza muromo inopfupisa gasi kubhururuka chinhambwe uye kuderedza kinetic simba kurasikirwa mugasi kuyerera, nekudaro ichiwedzera kukurumidza uye density yekuyerera kwegasi kunosangana nesimbi, uye kuwedzera goho rehupfu hwakatsetseka.

1.2.1.1 Circumferential Slot Nozzle

High pressure ultrasonic inopinda mumuromo tangentially. Zvadaro inobudiswa nekumhanya kukuru kuti iite vortex

Kugadzira 3D Kudhinda, China Inoda Kuvaka Yayo Yekuvandudza Chain Uye Maindasitiri Chain.

Mumakore maviri apfuura, kusimudzira kweiyo indasitiri yekuwedzera yekugadzira yakakwira kusvika padanho renyika. Zvinyorwa zvakaita se "Made in China 2025" uye "National Additive Manufacturing Industry Development Action Plan (2015-2016)" zvakaburitswa. Indasitiri yekuwedzera yekugadzira yakagadzirwa nekukurumidza. Hutano hwemabhizinesi akavakirwa tekinoroji huri kuwedzera. Pasinei neizvi, nekuti indasitiri yekugadzira iri mudanho rekutanga rebudiriro, ichiri kuratidza hunhu hwekuderera. Nyanzvi dzinobvuma kuti michina inotengeswa kunze kwenyika yave "kurwisa" musika weChina nehasha. Kutora michina yekudhinda simbi semuenzaniso, nyika dzekunze dzinoshandisa zvakabatanidzwa kutengesa kwezvinhu, software, zvishandiso uye maitiro. nyika yangu inofanirwa kukurumidza kutsvagisa uye kusimudzira hunyanzvi hwetekinoroji uye yekutanga matekinoroji, uye kugadzira yayo innovation cheni uye maindasitiri ketani.

Tarisiro yemusika yakanaka

Sekureva kwechishumo cheMcKinsey, kugadzirwa kwekuwedzera kuri pachinzvimbo chepfumbamwe pakati petekinoroji gumi nembiri ine zvinokanganisa hupenyu hwevanhu, pamberi pezvinhu zvitsva uye gasi reshale, uye zvinofungidzirwa kuti panosvika 2030 kugadzirwa kwekuwedzera kuchasvika A pamusika saizi inosvika madhora miriyoni imwe. Muna 2015, chirevo chakafambisa chirongwa ichi kumberi, chichipokana kuti panosvika 2020, ndiko kuti, makore matatu gare gare, saizi yepasi rose yekuwedzera yekugadzira musika inogona kusvika kubhenefiti ye550 bhiriyoni US madhora. Chirevo cheMcKinsey hachishamisi.

Lu Bingheng, mudzidzi weChinese Academy yeUinjiniya uye director weNational Additive Manufacturing Innovation Center, akashandisa "mana nehafu" kupfupisa tarisiro yemusika weramangwana rekuwedzera kugadzira.

Inopfuura hafu yekukosha kwechigadzirwa mune ramangwana yakagadzirwa;

Inopfuura hafu yekugadzirwa kwechigadzirwa inogadziriswa;

Inopfuura hafu yemhando dzekugadzira dzakazara;

Inopfuura hafu yezvitsva zvinogadzirwa nevagadziri.

Kuwedzera kwekugadzira ndiyo inokanganisa tekinoroji inotungamira kuvandudzwa kweindasitiri yekugadzira. Iyo tekinoroji yakakodzera kutsigira dhizaini dhizaini, yakagadziridzwa kugadzirwa, mugadziri innovation uye crowdsourcing kugadzira. "Kunyanya kukosha, kuwedzera kwekugadzira inyanzvi isingawanzoitiki inofananidzwa nenyika munyika yangu. Parizvino, tsvakurudzo yeChina pamusoro pekudhindwa kwe3D iri mberi kwenyika."

Lu Bingheng akati pari zvino, tichivimba nehombe ye3D yekudhinda simbi yeatomization uye michina yekugaya yakagadziridzwa nenyika yangu pachayo, China iri pachinzvimbo chepasi rose mukushandiswa kwezvikamu zvakakura zvinotakura zvinhu zvendege, uye inoshanda se boka rerubatsiro rwekutanga mukutsvagisa nekuvandudzwa kwendege dzemauto nendege huru. Uyezve, titanium alloy hombe-zvimiro zvikamu zvakashandiswa mukutsvagisa nekusimudzira ndege yekumhara giya uye C919.

Panyaya yekushandiswa, nyika yangu yakasimwa yemidziyo yegiredhi yegiredhi iri pachinhanho chechina pasirese, asi michina inotengeswa yekudhinda simbi ichiri kushoma, uye inonyanya kuvimba nekutenga kunze kwenyika. Nekudaro, sekureva kwaAcademician Lu Bingheng, chinangwa chese cheChina chekuwedzera kugadzirwa ndechekuwana yechipiri yakakura kwazvo yakasimwa kugona uye yechitatu yakakura kwazvo kugadzirwa kwemidziyo nekutengesa munyika mukati memakore mashanu; uye yechipiri yakakura kwazvo yakaiswa pasirese, misimboti michina uye yekutanga matekinoroji, uye kutengeswa kwemidziyo mukati memakore gumi. Wana "Made in China 2025" muna 2035.

Kubudirira kwemaindasitiri kunowedzera

Dhata inoratidza kuti avhareji yekukura kwekukura kwemusika wekuwedzera kugadzira mumakore matatu apfuura. Mwero wekusimudzira weindasitiri iyi muChina wakakwira kupfuura avhareji yepasi rose.

Signage: kazhinji inoreva izvo zvinoitwa kudzora mamwe manormative masisitimu mukati mekambasi

Zviratidzo, zvakadai se: zviratidzo zvemaruva uye uswa, hapana zviratidzo zvekukwira, nezvimwewo Kuderera, asi mumunda webasa, chiyero chekukura chinokurumidza zvikuru nekuda kwekuvandudzwa kwekuzivikanwa kwevatengi. "Kunyanya mukugadzirwa kwechigadzirwa nekugadzira, huwandu hwehurongwa hwedu hwakapetwa kaviri." Iyo Weinan 3D Printing Indasitiri Kurima Base muShaanxi Province, nerutsigiro rwehurumende yemuno, yakashandura zvakanakira tekinoroji yekudhinda ye3D kuita zvakanakira maindasitiri uye yakasimudzira kusimudzira neshanduko yemaindasitiri echinyakare. Chiitiko chakajairwa chekuona kukura kweboka.

Tichitarisa paindustry incubation pfungwa ye "3D printing +", haisi yekungogadzira iyo 3D printing industry, asi kutarisa pakugadzirwa kwe3D printing equipment, tsvakiridzo nekusimudzira nekugadzirwa kwe3D printing metal materials, uye kudzidziswa. yematarenda e3D ekudhinda anonangana nekushandisa. Yakadzika midzi mumaindasitiri anotungamira emuno, yakatarisana nekuitwa kwe3D kudhinda maindasitiri ekuratidzira maapplication, kukurumidza kubatanidzwa kwe3D kudhinda nemaindasitiri echinyakare, uye kuita akatevedzana e3D kudhinda + maindasitiri emhando dzakadai se3D kudhinda + ndege, mota, tsika nekugadzira, kukanda, dzidzo, nezvimwewo, nerubatsiro rwe 3D kudhinda Zvakanakira tekinoroji yekudhinda, gadzirisa matambudziko ehunyanzvi uye marwadzo emaindasitiri echinyakare, shandura nekusimudzira maindasitiri echinyakare, uye kuunza uye kupinza mhando dzakasiyana dzemabhizinesi madiki uye epakati tekinoroji.

Sekureva kwehuwandu, kubva muna Chivabvu 2017, huwandu hwemabhizinesi hwasvika makumi matanhatu nerimwe, uye anopfuura makumi mashanu mapurojekiti akadai se3D molds, 3D, 3D maindasitiri emuchina, 3D zvinhu, uye 3D tsika nekugadzira mapurojekiti akachengetwa, ayo anotarisirwa kuitwa. Zvinotarisirwa kuti panopera gore, huwandu hwemabhizinesi huchapfuura zana.

Activate innovation cheni uye indasitiri cheni

Kunyangwe nekukasira kusimudzira kweindasitiri yekuwedzera yekugadzira yenyika yangu, iyo indasitiri ichiri mumatanho ekutanga ebudiriro uye ichine hunhu hwekuderera. Nekudaro, kushaikwa kwekukura kwetekinoroji, mutengo wepamusoro wekushandisa, uye kutetepa kwekushandisa kwakakonzera kuti indasitiri yese ive mumamiriro e "madiki, akapararira uye asina simba". Kunyangwe makambani mazhinji akatanga kutsika mumunda wekuwedzera kugadzira, pane kushomeka kwemakambani anotungamira Inotungamirwa, chiyero cheindasitiri idiki. Academician Lu Bingheng akataura pachena kuti seimwe yeakakosha matekinoroji eremangwana shanduko yemaindasitiri, kuvandudzwa kwekugadzira kwekuwedzera kunofanirwa kukurumidzirwa, nekuti tekinoroji yekudhinda ye3D iri munguva yekuputika kwetekinoroji, nguva yekutanga indasitiri, uye. iyo "staking" nguva yemabhizinesi. Iko kudiwa kukuru kwemusika kunogona kufambisa kusimudzira tekinoroji uye munda wemidziyo, iyo inofanirwa kuchengetedzwa uye kushandiswa zvizere kutungamira nekutsigira kugadzirwa kwemidziyo yedu.

Ikozvino michina yakatengwa kunze kwenyika iri "kurwisa" musika weChinese nehasha. Pamidziyo yesimbi yekudhinda, nyika dzekunze dzinoshandisa mabundled ekutengesa zvinhu, software, midziyo, uye maitiro. Makambani eChinese anofanirwa kugadzira matekinoroji ekutanga uye matekinoroji ekutanga kuti vagadzire ivo pachavo hunyanzvi uye maketani emaindasitiri.

Indasitiri vemukati vakati kune yazvino indasitiri yekudhinda ye3D, dhigirii rekutsvagisa tekinoroji nekusimudzira rakashandiswa zvizere kuindasitiri, uye zvakawanda zvakabudirira tekinoroji zvinongori murabhoritari nhanho. Zvikonzero zvikuru zvechinetso ichi ndezvi: kutanga, nekuda kwezviyero zvakasiyana-siyana, kuwana Izvo zvigadziro hazvina kukwana, uye pane zvisingaoneki zvipingamupinyi zvekupinda; chechipiri, masangano ekutsvagisa kwesainzi uye mabhizinesi haana mhedzisiro, ari mumamiriro ekurwa ari ega, haana kodzero yekutaura munhaurirano dzeindasitiri, uye ari panjodzi; Indasitiri nyowani hainyatso kunzwisiswa, uye kune mapuzzle kana kusanzwisisana, zvichikonzera kunonoka kwekushandisa tekinoroji.

Iyo Yekuvandudza Maitiro eAtomization Pulverizing Equipment Mune Ramangwana

Pachine zvakawanda zvinoshomeka mukunzwisisa kwe 3D tekinoroji yekudhinda mune ese maficha eChina ekugadzira indasitiri. Tichitarisa kubva pamamiriro chaiwo ebudiriro, kusvika pari zvino kudhinda kwe3D hakusati kwawana maindasitiri akura, kubva kumichina kuenda kune zvigadzirwa kusvika kune masevhisi achiri muchikamu che "advanced toy". Nekudaro, kubva kuhurumende kuenda kumabhizinesi muChina, tarisiro yebudiriro ye 3D yekudhinda tekinoroji inowanzo zivikanwa, uye hurumende nenzanga kazhinji vanoteerera kukanganiswa kweramangwana 3D kudhinda simbi atomization pulverizing midziyo tekinoroji pakugadzirwa kwenyika yangu iripo, hupfumi, uye mienzaniso yekugadzira.

Zvinoenderana nedata reongororo, parizvino, kudiwa kwenyika yangu kweiyo 3D tekinoroji yekudhinda haina kutariswa pamidziyo, asi inoratidzwa mumhando dzakasiyana dze3D kudhinda zvigadzirwa uye kudiwa kwemaagency kugadzirisa masevhisi. Vatengi vemaindasitiri ndivo vane simba guru pakutenga michina yekudhinda ye3D munyika yangu. Midziyo yavanotenga inonyanya kushandiswa mundege, ndege, zvigadzirwa zvemagetsi, zvekufambisa, dhizaini, hunyanzvi hwetsika uye mamwe maindasitiri. Parizvino, huwandu hwakaiswa hwemaprinta e3D mumabhizinesi eChinese angangoita mazana mashanu, uye mwero wekukura wepagore ungangoita 60%. Kunyange zvakadaro, saizi yemusika iripo inongosvika zana remamiriyoni eyuan pagore. Kugona kudiwa kweR&D nekugadzirwa kwezvinhu zvekudhinda zve3D kwasvika panosvika bhiriyoni imwe yeyuan pagore. Nekuzivikanwa uye kufambira mberi kwehunyanzvi hwemichina, chiyero chinokura nekukurumidza. Panguva imwecheteyo, 3D kudhinda-inoenderana neyakachengeteswa masevhisi masevhisi ane mukurumbira, uye akawanda maajenti 3D kudhinda Kambani yemidziyo yakakura kwazvo mukuita laser sintering uye kushandiswa kwemidziyo, uye inogona kupa ekunze masevhisi ekugadzirisa. Sezvo mutengo wemudziyo mumwe uchiwanzopfuura 5 miriyoni yuan, kugamuchirwa kwemusika hakuna kukwira, asi iyo agency yekugadzirisa sevhisi yakakurumbira.

Zvizhinji zvezvinhu zvinoshandiswa munyika yangu 3D yekudhinda simbi yeatomization pulverizing michina inopihwa zvakananga nevanomhanyisa prototyping vagadziri, uye wechitatu-bato rekupa zvinhu zvakajairika haasati aitwa, zvichikonzera kudhura kwakanyanya kwezvinhu. Panguva imwecheteyo, hapana tsvakiridzo yekugadzirira hupfu yakatsaurirwa kudhinda kwe3D kuChina, uye pane zvakaomesesa zvinodikanwa pakugovera saizi yechikamu uye neokisijeni yemukati. Mamwe mayunitsi anoshandisa yakajairwa pfapfaidzo poda panzvimbo, iyo ine yakawanda isingashande.

Kuvandudzwa uye kugadzirwa kwezvinhu zvakasiyana-siyana ndiyo kiyi yekufambira mberi kwetekinoroji. Kugadzirisa mashandiro uye matambudziko emitengo yezvinhu kuchasimudzira zvirinani kusimudzira kwekukurumidza prototyping tekinoroji muChina. Parizvino, zvizhinji zvezvinhu zvinoshandiswa munyika yangu 3D kudhinda nekukurumidza prototyping tekinoroji inoda kutengwa kubva kunze kwenyika, kana vagadziri vemidziyo vakaisa simba rakawanda nemari yekuzvigadzira, izvo zvinodhura, zvichikonzera kuwedzera kwemitengo yekugadzira, ukuwo. zvinhu zvemumba zvinoshandiswa muchina uyu zvine simba rakaderera uye nemazvo. . Iko kugadzirwa kwe3D zvinyorwa zvekudhinda kwakakosha.

Titanium uye titanium alloy poda kana nickel-based uye cobalt-based superalloy poda ine yakaderera oxygen content, yakanaka particle size uye high sphericity inodiwa. Iyo poda particle size inonyanya -500 mesh, iyo okisijeni yemukati inofanira kunge yakaderera pane 0.1%, uye particle size inofanana Parizvino, yakakwirira-yekupedzisira alloy poda uye zvigadzirwa zvekugadzira zvichiri kunyanya kuvimba nekunze. Munyika dzekunze, zvigadzirwa nemidziyo zvinowanzounganidzwa uye kutengeswa kuti vawane purofiti yakawanda. Tichitora nickel-based powder semuenzaniso, mutengo wezvinhu zvakabikwa ungangoita 200 yuan/kg, mutengo wezvigadzirwa zvemumba unowanzoita 300-400 yuan/kg, uye mutengo wehupfu hunotengwa kunze kwenyika kazhinji unodarika 800 yuan/kg.

Semuyenzaniso, pesvedzero uye kuchinjika kwekuumbwa kwehupfu, inclusions uye zvimiro zvemuviri pane yakabatana tekinoroji ye3D yekudhinda simbi atomization poda milling michina. Naizvozvo, tichitarisa mashandisirwo ekushandiswa kweyakaderera okisijeni yemukati uye yakanaka particle size poda, zvichiri kudikanwa kuita basa rekutsvagisa senge dhizaini yekugadzira titanium uye titanium alloy poda, gasi atomization poda yekugaya tekinoroji yefine particle size poda, uye pesvedzero yehupfu hunhu pakuita kwechigadzirwa. Nekuda kwekuganhurirwa kwehunyanzvi hwekugaya muChina, zvakaoma kugadzirira poda yakatsetseka pari zvino, goho rehupfu rakaderera, uye zvirimo zveokisijeni nezvimwe zvisina kuchena zvakakwirira. Munguva yekushandiswa kwekushandisa, hupfu hunonyunguduka hunowanzoita kusaenzana, zvichiita kuti pave nepamusoro-soro ye oxide inclusions uye denser zvigadzirwa muchigadzirwa. Matambudziko makuru emumba alloy poda ari mumhando yechigadzirwa uye batch kugadzikana, zvinosanganisira: ① kugadzikana kwezvikamu zvehupfu (nhamba yekubatanidzwa, kufanana kwezvikamu); ② hupfu hwemuviri Kugadzikana kwekuita (particle size distribution, powder morphology, fluidity, loose ratio, etc.); ③ dambudziko regoho (yakaderera goho rehupfu mune yakamanikana particle size chikamu), nezvimwe.

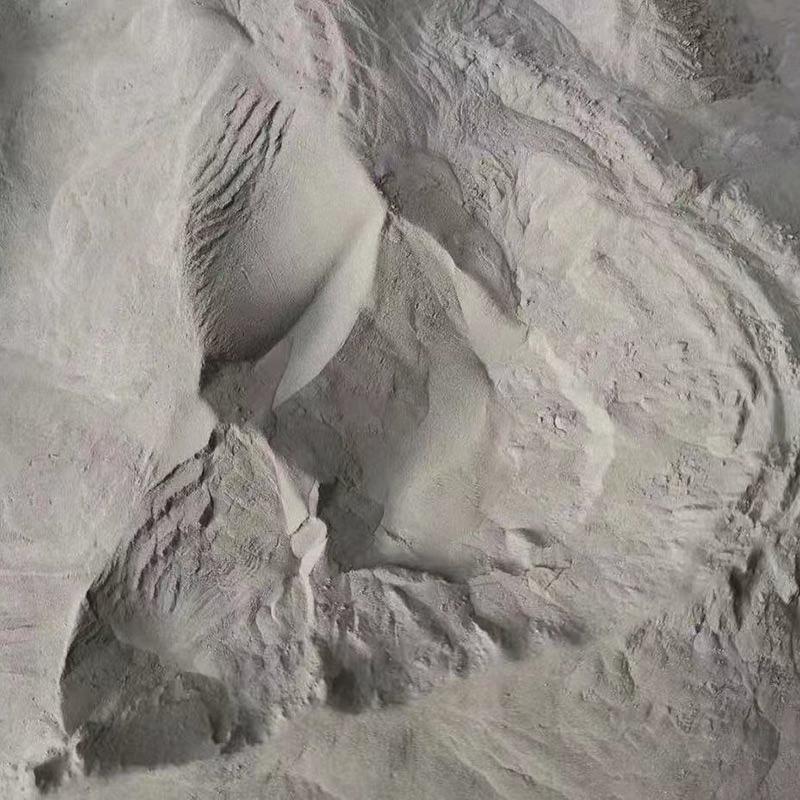

Product Display

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur