WAYA BONDING

ZIVO BASE FACT SHEET

Chii chinonzi Wire Bonding?

Wire bonding ndiyo nzira iyo kureba kwediki dhayamita yakapfava waya yesimbi inonamirwa kune inowirirana simbi pamusoro pasina kushandisa solder, flux, uye mune dzimwe nguva nekushandiswa kwekupisa kunopfuura 150 degrees Celsius. Simbi dzakapfava dzinosanganisira Goridhe (Au), Mhangura (Cu), Sirivha (Ag), Aluminium (Al) uye alloys akadai sePalladium-Silver (PdAg) nemamwe.

Kunzwisisa Wire Bonding Techniques uye Matanho eMicro Electronics Gungano Zvikumbiro.

Wedge Bonding Techniques / Maitiro: Ribhoni, Thermosonic Bhora & Ultrasonic Wedge Bond

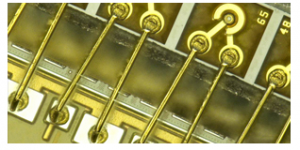

Wire bonding ndiyo nzira yekugadzira hukama pakati peiyo integrated circuit (IC) kana yakafanana semiconductor mudziyo nepasuru yayo kana leadframe panguva yekugadzira. Inoshandiswawo zvino inowanzoshandiswa kupa magetsi ekubatanidza muLithium-ion battery pack assemblies.Waya bonding inowanzoonekwa seyakanyanya kudhura uye inochinjika yeiyo iripo microelectronic interconnect technologies, uye inoshandiswa mune yakawanda semiconductor mapakeji anogadzirwa nhasi. kune akati wandei waya yekubatanidza matekiniki, anosanganisira: Thermo-Compression Wire Bonding:

Thermo-compression wire bonding (ichibatanidza kune zvingangoitika (kazhinji Au) pamwe chete pasi pesimba rinosunga rine tembiricha yakakwira, inodarika 300°C, kugadzira weld), yakatanga kugadzirwa kuma1950's ye microelectronics interconnects, zvisinei izvi zvaive. nekukurumidza yakatsiviwa neUltrasonic & Thermosonic bonding mu60's seyakanyanya kubatanidza tekinoroji. Thermo-compression bonding ichiri kushandiswa kune niche application nhasi, asi kazhinji inodziviswa nevagadziri nekuda kwekukwira (kazhinji kunokuvadza) tembiricha inodiwa kuitira kugadzira chisungo chinobudirira.Ultrasonic Wedge Wire Bonding:

Mumakore ekuma1960 Ultrasonic wedge wire bonding yakava nzira huru yekubatanidza nzira. Kushandiswa kweyepamusoro frequency vibration (kuburikidza neanoita resonating transducer) kune chekubatanidza chishandiso chine simba rimwechete rekusunga, yakabvumira waya dzeAluminiyamu neGoridhe kuti dzipinzwe patembiricha yekamuri. Iyi Ultrasonic vibration inobatsira pakubvisa tsvina (oxides, tsvina, etc.) kubva pazvisungo zvekubatanidza pakutanga kwekubatana, uye mukusimudzira intermetallic kukura kuti iwedzere kukura nekusimbisa chisungo. Mafambiro ekubatanidza mabhandi 60 – 120 KHz. The ultrasonic wedge technique ine two main process technologies: Hombe (inorema) kubatanidza waya kwewaya >100µm dhayamita mawayaKukochekera kwewaya (diki) kwe <75µm diameter wayaMienzaniso yezvakajairwa Ultrasonic bonding inowanika pano yewaya yakanaka uye pano kune waya hombe.Ultrasonic wedge wire bonding inoshandisa chaiyo bonding tool kana "wedge," inowanzo vakwa kubva kuTungsten Carbide (yeAluminium wire) kana Titanium Carbide (yeGoridhe wire) zvichienderana nemaitiro ekuita uye madhayamita ewaya; Ceramic tipped wedges kune akasiyana maapplication aripo zvakare.Thermosonic Wire Bonding:

Panodiwa kudziya kwekuwedzera (kazhinji kune Gold wire, ine bonding interfaces muhuwandu hwe100 - 250 ° C), maitiro anonzi Thermosonic wire bonding. Izvi zvine mabhenefiti makuru pamusoro pechinyakare thermo-compression system, sezvo tembiricha yakadzikira zvakanyanya inodiwa (Au bonding patembiricha yekamuri yataurwa asi mukuita haivimbike pasina kumwe kupisa).Thermosonic Ball Bonding:

Imwe fomu yeThermosonic wire bonding iBall Bonding (ona bhora rebhondi kutenderera pano). Iyi nzira inoshandisa ceramic capillary bonding chishandiso pamusoro pechinyakare wedge dhizaini kusanganisa akanakisa hunhu mune zvese thermo-compression uye ultrasonic bonding pasina zvinokanganisa. Thermosonic vibration inoita kuti tembiricha yekushisa irambe yakadzikira, nepo yekutanga yekubatanidza, iyo thermally-compressed bhora bond inobvumira waya uye yechipiri bond kuti iiswe mune chero nzira, kwete mumutsara neyekutanga bond, inova inomanikidza mu Ultrasonic waya bonding. . Kugadzira otomatiki, kukwirisa vhoriyamu, mabhora anosunga mabhora anomhanya zvakanyanya kupfuura Ultrasonic / Thermosonic (Wedge) mabhondi, zvichiita kuti Thermosonic bhora risungirire iyo inotungamira interconnect tekinoroji mumicroelectronics kwemakore makumi mashanu ekupedzisira.Ribbon Bonding:

Ribhoni kusungirirwa, kushandisa matepi esimbi akadzikama, kwave kuri kutonga muRF neMicrowave zvemagetsi kwemakumi emakore (ribhoni inopa kuvandudzwa kwakakura mukurasikirwa kwechiratidzo [ganda rekuita] maringe newaya yechinyakare). Marabhoni madiki eGoridhe, anowanzosvika 75µm paupamhi uye 25µm mukobvu, anobatanidzwa kuburikidza neThermosonic process ine hombe-flat-faced wedge bonding tool.Marabhoni eAluminium anosvika 2,000µm paupamhi uye 250µm mukobvu anogonawo kubatanidzwa ne Ultrasonic wedge process, se. chinodiwa chepasi loop, yakakwira density interconnects yakawedzera.

Chii chinonzi gold bonding wire?

Gold wire bonding inzira iyo waya yegoridhe inonamirwa pamapoinzi maviri mugungano kuti iite chinokochekera kana nzira yemagetsi. Kupisa, maultrasonics, uye simba zvose zvinoshandiswa kugadzira maattachment points ewaya yegoridhe.Maitirwo ekugadzira nzvimbo yekunamatira inotanga nekugadzirwa kwebhora regoridhe pamuromo wewaya bond tool, capillary. Iri bhora rinotsikirirwa panzvimbo yegungano rinopisa paunenge uchiisa zvese zviri zviviri application-chaiyo huwandu hwesimba uye frequency ye60kHz - 152kHz ye ultrasonic motion nechishandiso.Kana chisungo chekutanga chaitwa, waya ichashandiswa muhutongi hwakasimba. nzira yekugadzira iyo yakakodzera loop chimiro cheiyo geometry yegungano. Chisungo chechipiri, chinowanzonzi musono, chinobva chaumbwa kune imwe nzvimbo nekutsikirira pasi newaya uye kushandisa chibatiso kubvarura waya pabhandi.

Gold wire bonding inopa nzira yekubatanidza mukati mepakeji inobatisisa magetsi, ingangoita kurongeka kwehukuru kupfuura mamwe masoja. Pamusoro pezvo, waya dzegoridhe dzine yakakwira oxidation kushivirira kana ichienzaniswa nezvimwe zvinhu zvewaya uye yakapfava kupfuura mazhinji, ayo akakosha kune anotemesa nzvimbo.

Nzira yacho inogonawo kusiyana zvichienderana nezvido zvegungano. Nezvinhu zvinonzwisisika, bhora regoridhe rinogona kuiswa panzvimbo yechipiri yekubatanidza kuti igadzire zvose chisungo chakasimba uye "chinyoro" chisungo kudzivirira kukanganisa pamusoro pechikamu. Nenzvimbo dzakasimba, bhora rimwe chete rinogona kushandiswa sekutanga kwezvisungo zviviri, zvichiita "V" yakaumbwa chisungo. Kana chisungo chewaya chichida kuwedzera kusimba, bhora rinogona kuiswa pamusoro pemusono kugadzira chisungo chekuchengetedza, kuwedzera kugadzikana uye kusimba kwewaya. Iwo akawanda akasiyana maapplication uye akasiyana kune waya bonding anenge asina magumo uye anogona kuwanikwa kuburikidza nekushandisa otomatiki software paPalomar's waya bond masisitimu.

Wire bonding development:

Kubatana kwewaya kwakawanikwa muGermany kumakore ekuma1950 kuburikidza nekuongorora kwakajeka uye kwakagadziridzwa kuita nzira inodzorwa zvakanyanya. Nhasi inoshandiswa zvakanyanya kune magetsi anobatanidza semiconductor machipisi kurongedza anotungamira, disk drive misoro kune pre-amplifiers, uye mamwe akawanda maapplication anobvumira zvinhu zvemazuva ese kuita zvidiki, "smarter", uye zvakanyanya kushanda.

Bonding Wires Applications

Iko kuwedzera kweminiaturization mumagetsi kwakaguma

mukubatanidza waya dzichiva zvakakosha zvinoumba

magungano emagetsi.

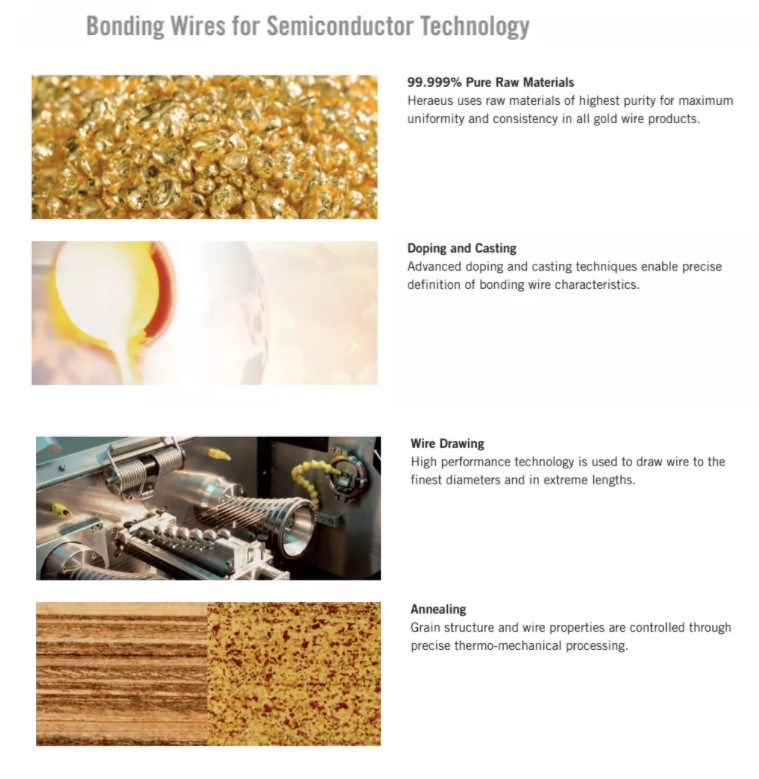

Nechinangwa ichi yakanaka uye ultrafine bonding waya dze

goridhe, aluminium, mhangura uye palladium inoshandiswa. Highest

zvinodiwa pamhando yavo, kunyanya maererano

kusvika pakufanana kwezvinhu zvewaya.

Zvichienderana nemakemikari avo uye chaiwo

zvivakwa, tambo dzekubatanidza dzinogadziriswa kune kusungirirwa

nzira yakasarudzwa uye kune otomatiki bonding michina se

pamwe nematambudziko akasiyana-siyana mumatekinoroji egungano.

Heraeus Electronics inopa huwandu hwechigadzirwa

kune zvakasiyana-siyana zvekushandisa zve

Indasitiri yemotokari

Telecommunications

Semiconductor vagadziri

Consumer goods industry

Heraeus Bonding Wire zvigadzirwa mapoka ndeaya:

Bonding waya dzekushandisa mupurasitiki yakazara

electronic components

Aluminium nealuminium alloy bonding waya dze

maapplication ayo anoda yakaderera kugadzirisa tembiricha

Mhangura yekubatanidza waya sehunyanzvi uye

mari inoshandiswa kune waya dzegoridhe

Yakakosha uye isina-yakakosha simbi yekubatanidza ribhoni ye

kubatanidza magetsi ane nzvimbo huru dzekusangana.

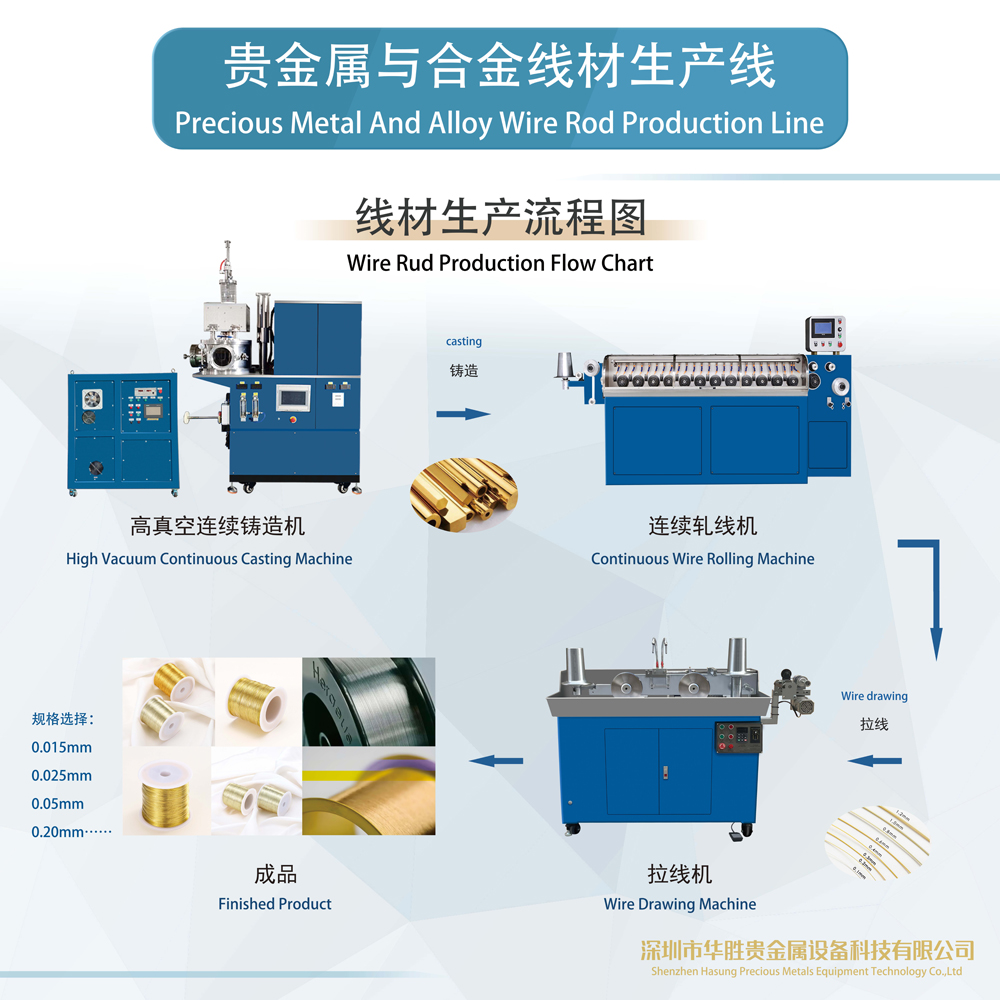

Bonding Wires Production Line

Nguva yekutumira: Jul-22-2022