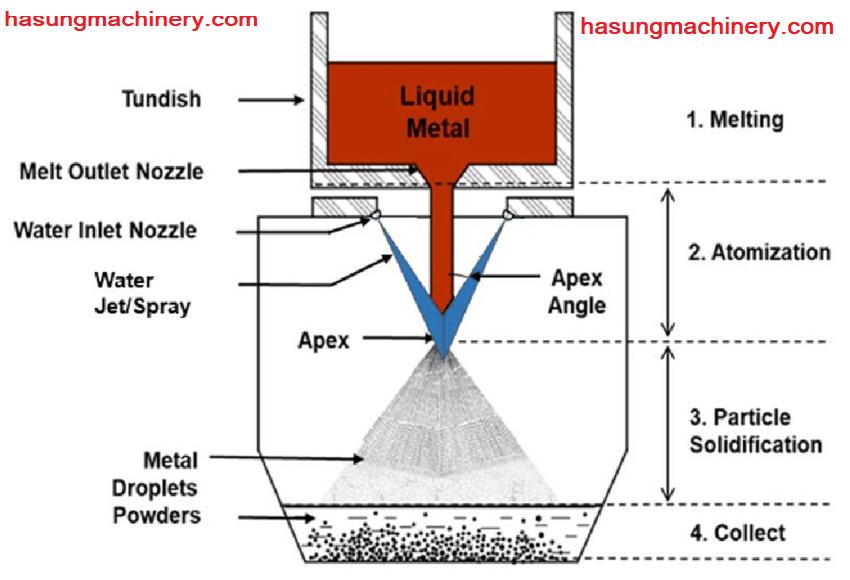

Iyi midziyo inonyanya kushandiswa kugadzira simbi hupfu kana granule mune atomization. chamber nehigh pressure water atomization nzira mushure mesimbi kana simbi alloy. kunyungudutswa pasi penzvimbo yekudzivirira gasi kana mhepo yakajairika. Mutengo wekushandisa wemuchina uye mutengo wekugadzira hupfu wakaderera. Metal Powder Water Atomization Equipment imhando yekugadzira hupfu apo simbi kana musanganiswa wemvura inodimburwa kuita mabeads madiki nemvura inokurumidza (atomization medium) inozungunuka kana dzimwe nzira, inoteverwa nekuvaka kuita hupfu hwakasimba. Chero zvinhu zvinogona kuumba mvura inogona kuve atomize uye kuita hupfu. The high-pressuremvura atomizationtekinoroji inogona kugadzira mari uye nemazvo kugadzira MIM simbi amalgam poda, yakasarudzika yakabatwa simbi poda, inokurumidza simbi poda, yakakosha simbi poda, mhangura-yakavakirwa poda yekomboni, uye super musanganiswa Powder, zvichingodaro. Iyo inonyanya kushandiswa ndeye gasi atomization Equipment uye mvura atomization Equipment. Munguva yenguva yakashandiswa atomization poda yekuendesa maitiro, nyungudutsa simbi isina kucheneswa kuita inonyatso shandiswa amalgam fluid (yakawanda zvikuru inopisa pa100-150 ℃) nehita yemagetsi kana hita yekugamuchira, wozopinzwa mu tundish pamusoro peatomizing spout. Mvura yakakoniwa inoyerera ichibuda paburi rinoteuka nechepazasi petundish, uye kana ichipinda nemumuromo, inogadzirwa maatomu kuita mabeads akatsetseka kana ikasangana nemhepo inokurumidza kana rwizi rwemvura. Madonhwe eatomu anokurumidza kuomeswa kuita musanganiswa weupfu mukamuri yakavharwa yeatomizing. Kakawanda, iyo gasi isina basa atomized poda zvimedu zvakatenderedza, zvine yakaderera okisijeni yemukati (pasi pe100 × 10), uye inogona kugadzirwa zvakananga kuita zvinhu zvakashongedzwa ne thermoforming innovation, (semuenzaniso, inopisa isostatic kusvina). Mvura yeatomu yehupfu zvidimbu ndeyezvikamu zvakawanda zvisingatarisike zvimiro zvine huwandu hweokisijeni (pamusoro pe600 × 10) uye inofanirwa kudzikamiswa. Iyo ine hukuru hwekumanikidza uye inogona kutonhora-kusvinwa mumichina zvikamu.

Kushanda musimboti

Iyo nzira inosanganisirwa nekuendesa simbi hupfu nemvura atomization pummeling kugadzirisa giya ine nhoroondo refu. Kare, vanhu vaidurura simbi ine mvura mumvura voiputika kuita zvidimbu zvesimbi, izvo zvaishandiswa sezvinhu zvisina kucheneswa kugadzira simbi; kusvika panguva ino, kune vanhu vanodurura mvura inotungamira yakananga mumvura kugadzira pfuti dzemutobvu. Iyo mvura atomization pounding strategy inoshandiswa kugadzira coarse compound powder. Nhungamiro yekutenderera yakaenzana neyakambotaurwa inobvumira mvura kupusha simbi yemvura, asi iyo inoparadza goho yakagadziridzwa zvakanyanya. Kugadzira yakakasharara musanganiswa poda nemvura atomization yekupomba giya, iyo goridhe rakakasharara rinofanirwa kunyungudutswa muheater kutanga, uye iyo goridhe yemvura inofanirwa kupisa zvakanyanya kutenderedza makumi mashanu madhigirii. Zvadaro, panguva iyoyo, yakapinzwa mu tundish. Tanga iyo yakakwira-kudzvanywa kwemvura siphon isati yapinzwa goridhe fluid, uye rega iyo yakanyanya-kudzvanywa mvura atomization gadget itange iyo workpiece. Mvura yegoridhe iri mu tundish inopinda nepakati pebhara yopinda muatomizer kuburikidza neinoteuka spout pazasi pesumbu. Iyo atomizer ndiyo yakakosha giya rekuburitsa goridhe rakaomeswa poda ine yakakwira tension yemvura mhute. Hunhu hweatomizer hunoonekwa nehunyanzvi hunoparadza hwehupfu hwesimbi. Pasi pekuita kwemvura yakakwira-kudzvanywa kubva paatomizer, mvura yegoridhe inogara ichitsemurwa kuita mabhero akanaka, ayo anowira mumvura inotonhorera mugajeti, uye nekukurumidza simendi kuita amalgam poda. Muchinyakare yakakwira-kudzvanywa kwemvura atomization maitiro ekuunza simbi hupfu, iyo simbi hupfu inogona kuunganidzwa nguva dzose, asi hunyoro hunyoro hwesimbi hucharasika nemvura yeatomu. Nokuda kwepamusoro-kudzvinyirira mvura atomization, chinhu cheatomi chakazara mu gadget yeatomization, yakakurumidza, yakapepetwa, (kana ichikosha, inogona kunyatsoomeswa, kazhinji inotumirwa zvakananga kubva kune inotevera hurongwa.) hapana kushaikwa kwehupfu hweamalgam mukutenderera kwese.asi hupfu hwesimbi hune mwero hucharasika nemvura yeatomu. Nokuda kweatomization yemvura yepamusoro-soro, chinhu cheatomi chakazara mugajeti yeatomization, yakakurumidza, yakapepetwa, (kana ichikosha, inogona kunyatsoomeswa, kazhinji inotumirwa zvakananga kubva kune inotevera hurongwa.) hapana kushaikwa kwehupfu hweamalgam mukutenderera kwese.asi hupfu hwesimbi hune mwero hucharasika nemvura yeatomu. Nokuda kweatomization yemvura yepamusoro-soro, chinhu cheatomi chakazara mugajeti yeatomization, yakakurumidza, yakapepetwa, (kana ichikosha, inogona kunyatsoomeswa, kazhinji inotumirwa zvakananga kubva kune inotevera hurongwa.) hapana kushomeka kwehupfu hweamalgam mukutenderera kwese.

Kurongeka kwakazara kwesimbi poda mvura atomization hardware inosanganisira zvikamu zvinotevera: Kunyunguduka chikamu: Unogona kusarudza yepakati frequency simbi yekunyungudutsa choto kana yakakwira-frequency simbi yekunyungudutsa choto. Kukwanisa kwechoto kunoenderana nehuwandu hwekugadzirisa hupfu hwesimbi. Iwe unogona kusarudza 50 kg yevira kana 20 kg yevira. Atomization chikamu: Ichi chikamu chemidziyo isiri-yakajairwa midziyo, iyo inofanirwa kugadzirwa uye kurongeka zvinoenderana nenzvimbo yenzvimbo yemugadziri, kunyanya kusanganisira tundish: kana tundish inogadzirwa munguva yechando, inoda kuve isati yapisa; Atomizer: Iyo atomizer inokanganisa iyo yakanyanya-kudzvanywa mvura kubva kune yakakwira-kudzvanywa kwemvura pombi nekumhanya kwakafanotemerwa uye kona pakatarisana nemvura yegoridhe kubva mu tundish, ichiipwanya kuita madonhwe esimbi. Pasi pekumanikidzwa kwepombi imwechete, huwandu hwehupfu hwesimbi yakatsetseka mushure meatomu ine hukama neatomizer kushanda kweatomizer; atomization cylinder: inzvimbo iyo alloy poda inogadziriswa, yakapwanyika, inotonhorera uye inounganidzwa. Kuti udzivise iyo superfine alloy poda kubva pakurasikirwa nemvura, iyo yakagadzirwa alloy poda inofanirwa kubvumidzwa kumira kwenguva yakati rebei mushure meatomization pulverizing, yozoiswa mubhokisi rekugamuchira hupfu. Post-processing chikamu: poda yekuunganidza bhokisi: inoshandiswa pakuunganidza atomized alloy powder, kupatsanurwa uye kubviswa kwemvura yakawandisa; kuomesa choto: kuomesa nyoro alloy poda nemvura; muchina wekuongorora: kuongorora iyo alloy poda, Iyo yakaomesesa alloy poda isingasangane nezvakatsanangurwa inogona kushandiswa seyakagadziridza zvinhu kuti zvinyunguduswe zvakare uye atomize.

Iyo yekupedzisira-yakanyanya kudzvanywa simbi poda mvura atomization michina ine zvinotevera maitiro

1-Inogona kushandiswa kune akawanda masimbi uye musanganiswa poda, uye mutengo wekugadzira wakaderera.

2-Inogona kuronga subspherical poda kana sporadic poda.

3-Nekuda kwekukasira simende uye pasina kuparadzaniswa, akawanda akasiyana akasarudzika amalgam poda anogona kugadzirira.

4-Iyo poda molecule saizi inogona kusvika painodiwa kusvika nekushandura iyo yakakodzera sisitimu.

Inopa mhando yesimbi yekukanda

Kuti uwane rumwe Ruzivo Ndapota

Titumire email :-info@hasungmachinery.com sales@hasungmachinery.com

Webhusaiti: - www.hasungcasting.comhttps://hasungmachinery.com/

Nguva yekutumira: Jun-30-2022