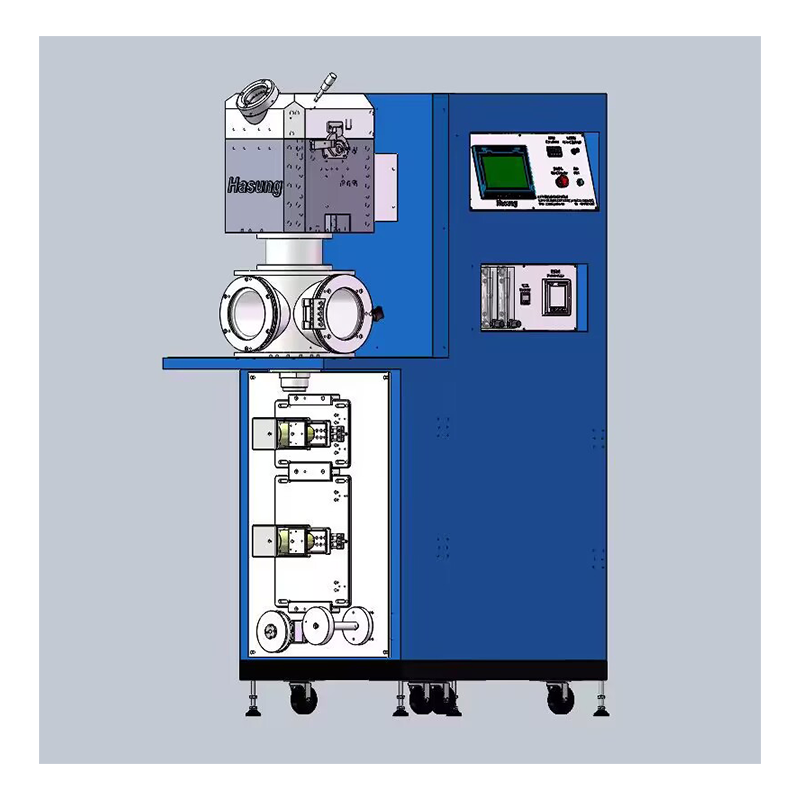

Hasung-Yakakwirira Vacuum Inoenderera Kukandira Equipment YeMasimbi Akakosha

1, Equipment Tsanangudzo:

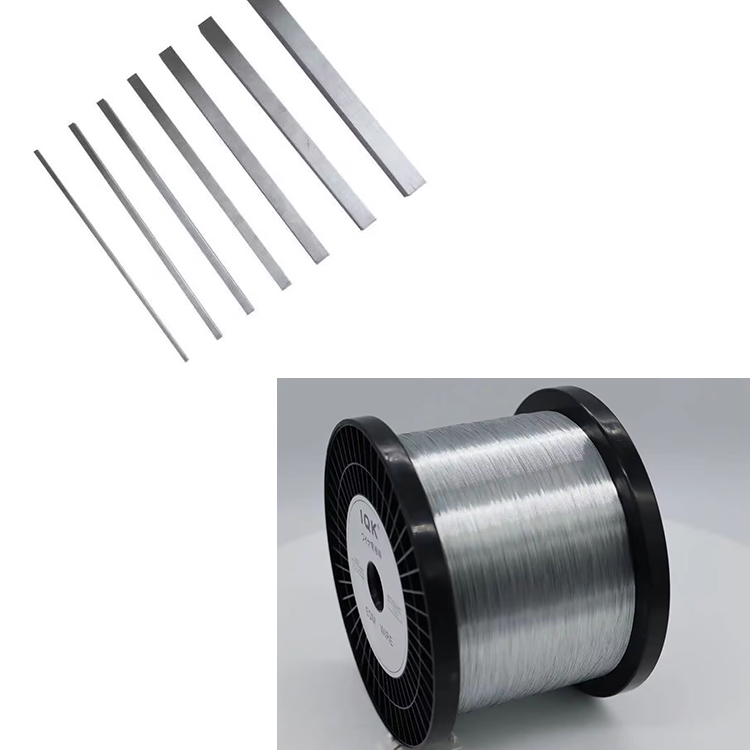

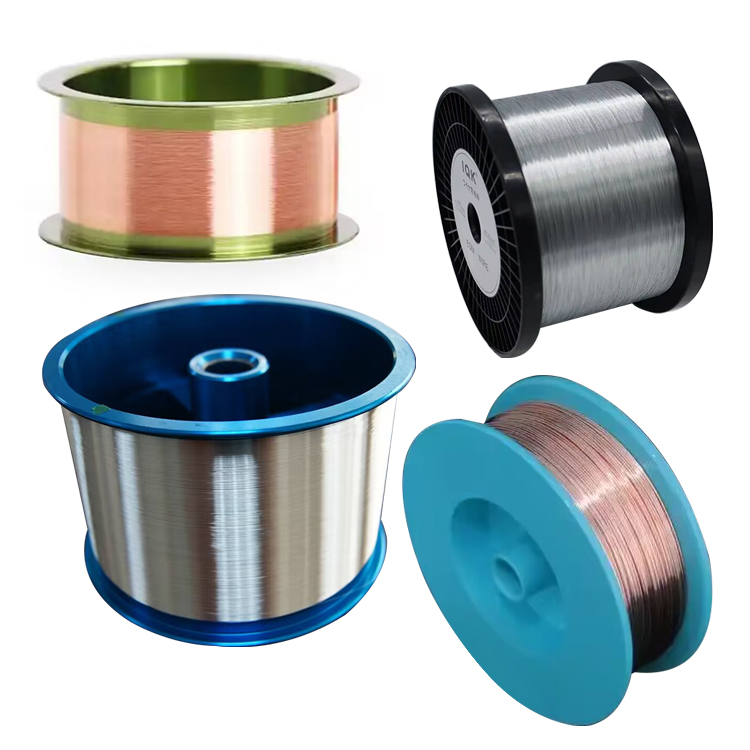

1. Mudziyo uyu unonyanya kushandiswa kuenderera mberi nekukandira imwe chete crystal copper bars, single crystal silver bars, uye single crystal gold bars, uye inogonawo kushandiswa kuenderera mberi kukanda kugadzirwa kwemamwe simbi nema alloys.

2. Iyi midziyo ndeye yakatwasuka choto muviri. Zvinhu zvakasvibirira, crucible, uye crystallizer zvinoiswa muvharo yevira yakavhurwa kubva kumusoro, uye crystallization inotungamira tsvimbo inoiswa muchikamu chezasi chechoto chevira. Kutanga, kristaro inodhonzwa kubva mukunyunguduka nehumwe hurefu kuburikidza nekristaro gwara tsvimbo, uye ipapo tsvimbo yekristaro inogadziriswa pamushini wemhepo yekudhirowa nekuunganidza.

3. Ichi chigadziro chinotora chigadziko chekubata zvizere chigadziro chekugadzirisa hurongwa nemagetsi akawanda ekucherechedza kuti anyatsogadzirisa kutonhora kwechoto uye crystallizer, kuwana mamiriro ekugara kwenguva refu anodiwa pakukura kwekristaro; Zviito zvekudzivirira zvakawanda zvinogona kuitwa kuburikidza nemidziyo yekutarisa, sekudonha kwezvinhu kunokonzerwa nekupisa kwechoto, kusakwana vacuum, mvura iri pasi pekumanikidzwa kana kushomeka, etc. Iyo midziyo iri nyore kushanda, uye iyo mikuru parameter yakaiswa inosanganisira tembiricha yevira, tembiricha ye kumusoro, pakati, uye pasi zvikamu zvekristallizer, pre kudhonza kumhanya, crystal kukura kudhonza kumhanya (pamwe ne inch mode, zvinoreva kudhonza kwenguva uye kumira kwenguva yakati. yenguva), uye akasiyana maalarm values.

Hasung Yakakosha Metal Yakazara Otomatiki Inoenderera Inokanda Muchina

2, Main tekinoroji paramita yemidziyo:

1. Rudzi: Vertical, automatic control, automatic heat.

2. Yese magetsi ekupa magetsi: matatu-chikamu 380V, 50Hz matatu-chikamu

3. Kupisa simba: 20KW

4. Nzira yekupisa: Induction kupisa (isina ruzha)

5. Kukwanisa: 8kg (goridhe)

6. Nguva yekunyunguduka: 3-6 maminitsi

7. Maximum tembiricha: 1600 madhigirii Celsius

6. Shamhu yemhangura dhayamita: 6-10m

7. Vacuum degree: Cold state<6 67× 10-3Pa

8. Tembiricha: 1600 ℃

9. Shamhu yemhangura yekudhonza kumhanya: 100-1500mm/min (inogadziriswa)

10. Masimbi anokandwa: goridhe, sirivha, mhangura, uye alloy zvinhu.

11. Nzira yekutonhodza: Kutonhodza mvura (tembiricha yemvura 18-26 degrees Celsius)

12. Kudzora maitiro: Siemens PLC + touch screen intelligent control

13. Equipment size: 2100 * 1280 * 1950mm

14. Kurema: Inenge 1500kg. High vacuum: inenge 550kg.

3. Tsanangudzo huru yezvimiro:

1. Furnace body: Muviri wechoto unotora vertical double-layer water-cooled structure. Chivharo chechoto chinogona kuvhurwa kuti zvive nyore kuisa macrucibles, crystallizers, uye mbishi zvinhu. Pane hwindo rekucherechedza pane chikamu chepamusoro chevhavha yevira, iyo inogona kutarisa mamiriro ezvinhu akanyungudutswa panguva yekunyunguduka. Induction electrode flanges uye vacuum pipeline flanges zvakarongwa zvakaenzanirana munzvimbo dzakasiyana dzehurefu pakati pechoto chemoto kuunza induction electrode majoini uye kubatana neiyo vacuum unit. Iyo yevira yepasi ndiro yakashongedzerwa ine crucible rutsigiro furemu, iyo inoshandawo semurwi wakamisikidzwa kugadzirisa nemazvo nzvimbo yekristaro, kuve nechokwadi chekuti gomba repakati rekristaro rakatarisana nemugero wekuvharisa pandiro yepasi pechoto. Zvikasadaro, iyo crystallization inotungamira tsvimbo haizokwanisi kupinda mukati meiyo crystallizer kuburikidza nekuvharisa chiteshi. Kune zvindori zvitatu zvakanyoroveswa nemvura pamadziro ekutsigira, zvinoenderana nepamusoro, pakati, uye pasi pezvikamu zvekristallizer. Tembiricha yechikamu chimwe nechimwe chekristaro inodzorwa chaizvo nekudzora kuyerera kwemvura inotonhorera. Kune mana thermocouples pane yekutsigira furemu, ayo anoshandiswa kuyera tembiricha yekumusoro, yepakati, uye yakaderera zvikamu zvecrucible uye crystallizer, zvichiteerana. Iyo yekubatanidza pakati pe thermocouples uye kunze kwechoto iri pachoto chepasi ndiro. Chigadziko chekuburitsa chinogona kuiswa pazasi pechitsigiro chesimbi kudzivirira tembiricha yekunyunguduka kuti isayerera yakananga pasi kubva kune inochenesa uye ichikonzera kukanganisa kumuviri wechoto. Kune zvakare diki diki rinobvisika vacuum chamber iri pakati penzvimbo pane yepasi ndiro yechoto. Pazasi pekamuri yekuvhaira ine organic girazi kamuri iyo inogona kuwedzerwa ine anti-oxidation ajenti kuvandudza kuvharika kwekuvharisa kwewaya yakanaka. Izvo zvinhu zvinogona kuwana iyo anti oxidation mhedzisiro pamusoro pedanda remhangura nekuwedzera anti-oxidation mumiriri kune organic girazi mhango.

2. Crucible uye Crystallizer: The crucible uye crystallizer yakagadzirwa nepamusoro-kuchena graphite. Pazasi pe crucible ndeye conical uye yakabatana kune crystallizer kuburikidza neshinda.

3. Vacuum system:

1. Pombi yemidzi

2. Pneumatic high vacuum disc valve

3. Electromagnetic high vacuum inflation valve

4. High vacuum gauge

5. Low vacuum gauge

6. Muviri wevira

7. Pneumatic high vacuum baffle valve

8. Cold trap

9. Diffusion pombi

4. Kudhirowa uye kumonereka michina: Kuramba kuchikandwa kwemhangura kunosanganisira mavhiri ekutungamira, madhiri akanyatsokonesa, madhairekitori emitsara, uye nzira dzekumonera. Gumbo rinotungamirira rinoita basa rekutungamirira uye rekumisa, uye chinhu chekutanga chinopfuura tsvimbo yemhangura painobuda muchoto ndiyo vhiri rinotungamirira. Iyo crystallization inotungamira tsvimbo inogadzikwa pane chaiyo screw uye linear gwara mudziyo. Tsvimbo yemhangura inotanga kudhonzwa kubva muchoto chevira (pre kudhonzwa) kuburikidza nemutsara wekufamba kwekristaro gwara tsvimbo. Kana tsvimbo yemhangura inopfuura nepavhiri rekutungamira uye iine humwe hurefu, iyo yekubatanidza nekristalllization gidhi tsvimbo inogona kugurwa. Zvadaro inogadziriswa pamushini wekupeta uye inoramba ichikwevera tsvimbo yemhangura kuburikidza nekutenderera kwemuchina wekupeta. Iyo servo mota inodzora mutsara wekufamba uye kutenderera kwemuchina unomonereka, unogona kunyatso kudzora kuenderera kunoramba kuchikanda kumhanya kwetsvimbo yemhangura.

5. Simba remagetsi e-ultrasonic power supply rinotora German IGBT, iyo ine ruzha rushoma uye kuchengetedza simba. Iyo tsime inoshandisa tembiricha yekudzora zviridzwa zvekudziya kwakarongeka. Magadzirirwo emagetsi emagetsi

Kune overcurrent, overvoltage mhinduro uye maseketi ekudzivirira.

6. Kudzora sisitimu: Iyi midziyo inotora chidzitiro chekubata zvizere otomatiki dhizaini ine michina yakawanda yekutarisa kunyatso kudzora tembiricha yechoto uye crystallizer, kuwana iyo yakareba yakagadzikana mamiriro anodiwa kuti tsvimbo yemhangura irambe ichikanda; Zviito zvekudzivirira zvakawanda zvinogona kuitwa kuburikidza nemidziyo yekutarisa, senge kudonha kwezvinhu kunokonzerwa nekupisa kwechoto, kusakwana vacuum, mvura iri pasi pekumanikidzwa kana kushomeka, etc. Midziyo yacho iri nyore kushanda uye iyo mikuru mikuru yakaiswa.

Kune tembiricha yechoto, tembiricha yekumusoro, yepakati, uye yakaderera zvikamu zvekristaro, pre kudhonza kumhanya, uye kristaro kukura kudhonza kumhanya.

Uye akasiyana maalarm values. Mushure mekuisa akasiyana ma parameter, mukugadzirwa kwemhangura tsvimbo inoenderera mberi ichikanda, chero kuchengetedzwa kuchichengetedzwa.

Isa crystallization guide rod, isa zvinhu zvakasvibirira, vhara gonhi rechoto, cheka chinongedzo pakati petsvimbo yemhangura uye crystallization gidhi tsvimbo, uye uibatanidze kumuchina unomonereka.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur